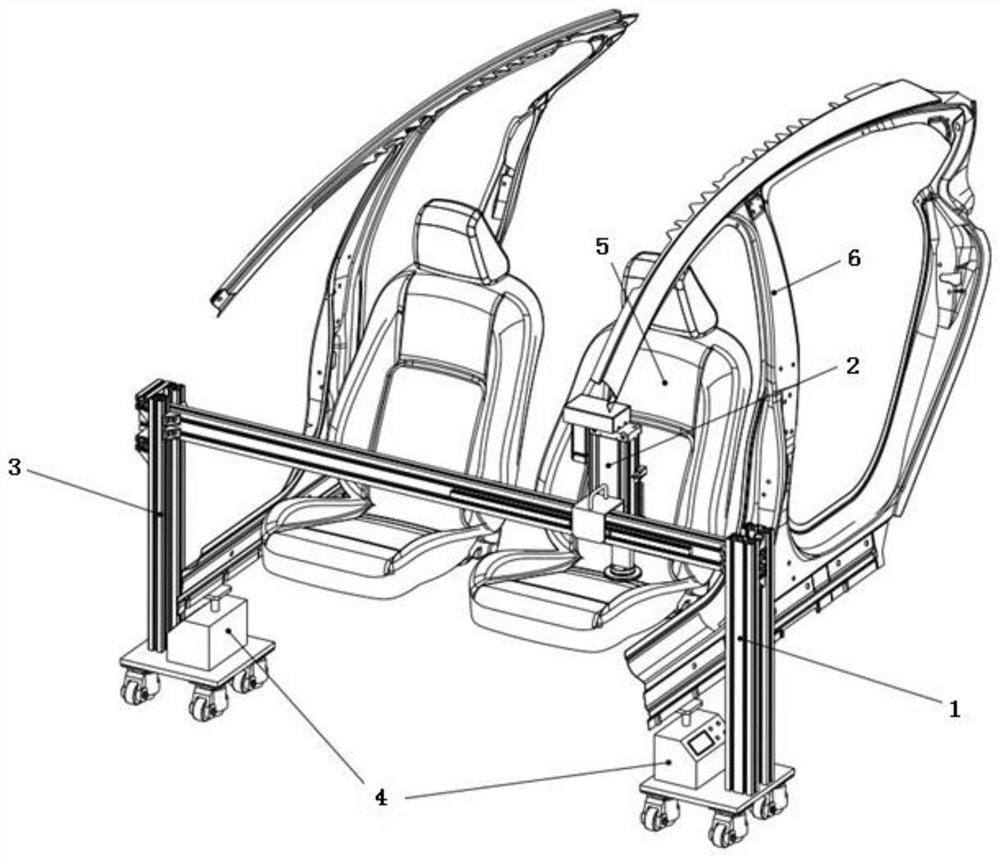

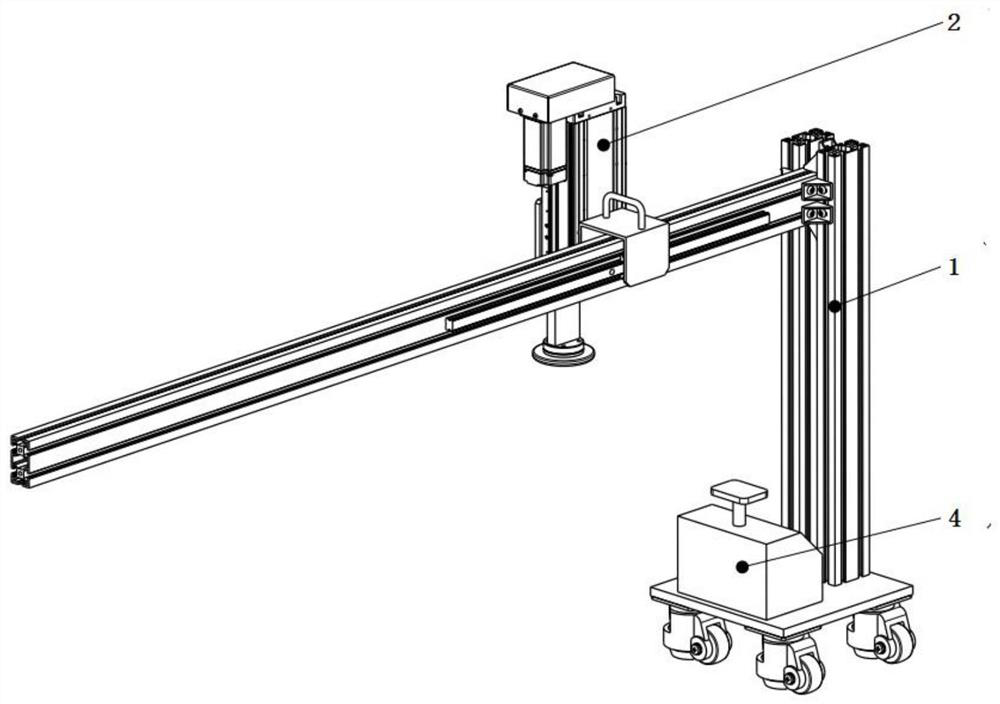

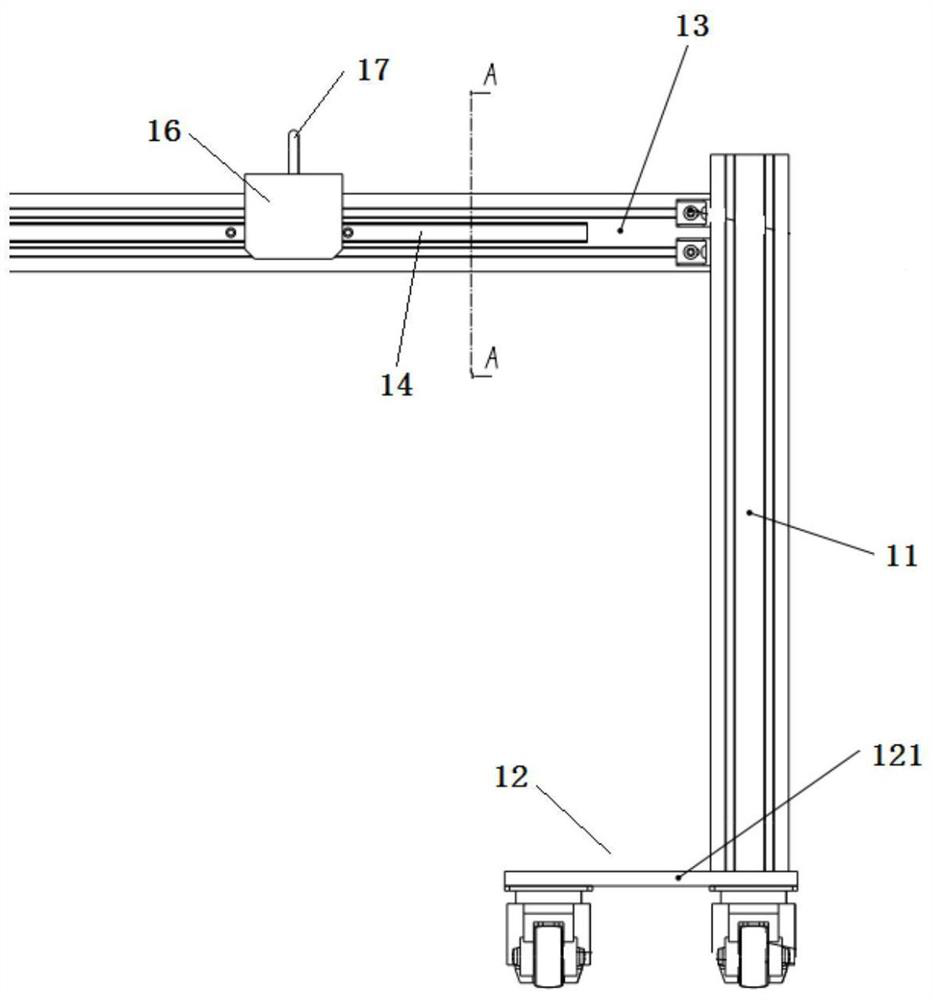

A kind of automobile seat hardness in-the-loop testing equipment and testing method

A technology of car seats and testing equipment, which is applied in the direction of elastic testing, testing material hardness, testing of machine/structural components, etc. It can solve problems such as unstable product subjective evaluation, difficult definition of hardness index, and difficult judgment of pass rate. Achieve the effects of fast and flexible switching and locking the test position, eliminating human interference, and stabilizing the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The vehicle seat hardness-in-the-loop test equipment and test method were used to press the measurement point of the A seat by 30 mm, and then unload at the same speed. Read the force value at 30mm on the curve, the first time is 150N, the second time is 158N, the third time is 165N, and the average value is 157.7N.

Embodiment 2

[0071] The vehicle seat hardness in-ring test equipment and test method are used to press the B seat by 30mm at the same point, and then unload at the same speed. Read the force value at 30mm on the curve, the first time is 173N, the second time is 181N, the third time is 190N, and the average value is 181.3N.

[0072] From the results obtained in Example 1 and Example 2, it can be seen that the force of seat B is 23.6 N greater than that of seat A by pressing the same point at the same depth, indicating that seat B is harder than seat A. If the enterprise takes more than 180N as the unqualified index of seat hardness, the B seat is judged to be unqualified.

Embodiment 3

[0074] Using the vehicle seat hardness-in-the-loop testing equipment and testing method, the hardness comfort test is carried out on the left and right A and B points of a certain seat along the vehicle transverse direction. Corresponding point positions, press 30mm into the two points respectively, then unload at the same speed, and read the force value at 30mm on the curve. If point A is 150N for the first time, 158N for the second time, and 165N for the third time, the average value is 157.7N; point B is 173N for the first time, 181N for the second time, and 190N for the third time, and the average value is calculated. The value is 181.3N. Point B is 23.6N larger than point A, indicating that point B is harder than point A. If the difference between the left and right of the company exceeds 20N as the unqualified index of seat hardness, the seat will be judged as unqualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com