a washing machine

A washing machine and inner tub technology, applied in the field of washing machines, can solve problems such as washing water discharge, and achieve the effects of improving washing cleanliness, simple structure, and avoiding incomplete washing of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment of the present invention in order to remove the washing machine inner cylinder 1 after the clothing is separated from the water flow, and to achieve the washing machine work process of the inner cylinder 1 sealed water for normal washing, the following settings:

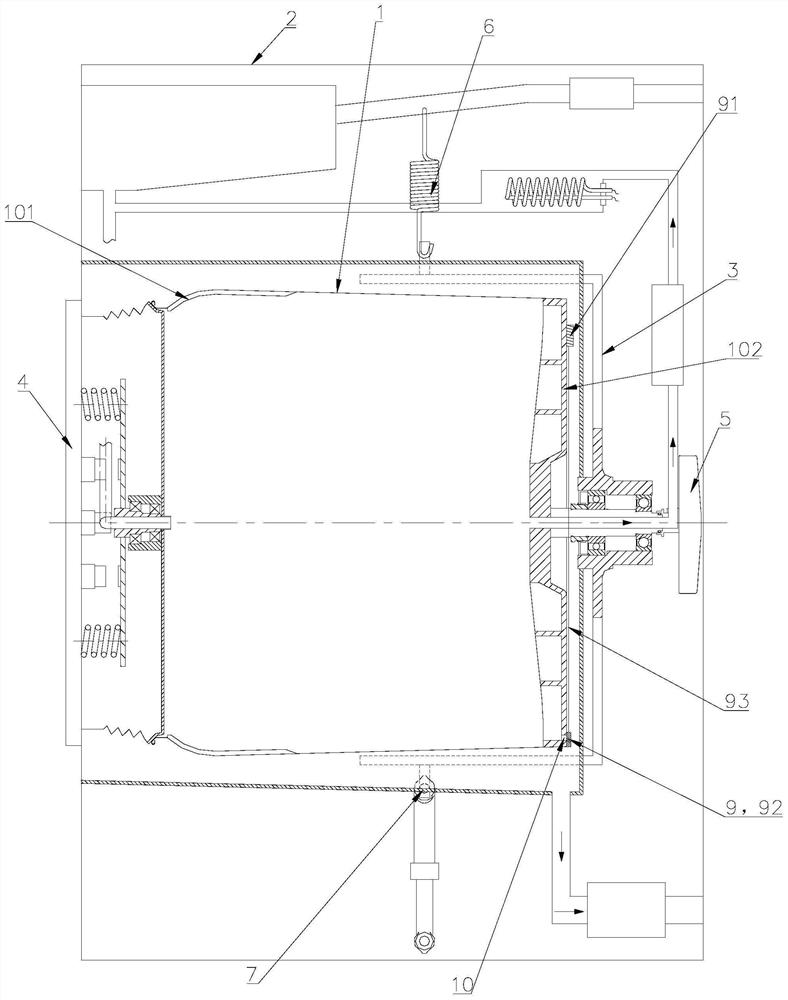

[0057] as Figures 1 through 4 As shown in the present embodiment, a washing machine is introduced, the inner cylinder of the washing machine 101 is a closed container after the door cover 4 is fastened, the bottom of the inner cylinder 102 has at least one drain 10, the drainage port 10 is provided along the bottom of the inner cylinder 102 radially moving open and closed the sealing valve 9, the valve body of the sealing valve 9 when the inner cylinder 1 rotates at high speed 92 moves radially in the center direction along the bottom of the inner cylinder 102 under the action of centrifugal force, in order to open the drainage port 102 provided by the bottom of the inner cylinder 102.

[0058] In the p...

Embodiment 2

[0070] Embodiment of the present invention in order to remove the washing machine inner cylinder 1 after the clothing is separated from the water flow, and to achieve the washing machine work process of the inner cylinder 1 sealed water for normal washing, the following settings:

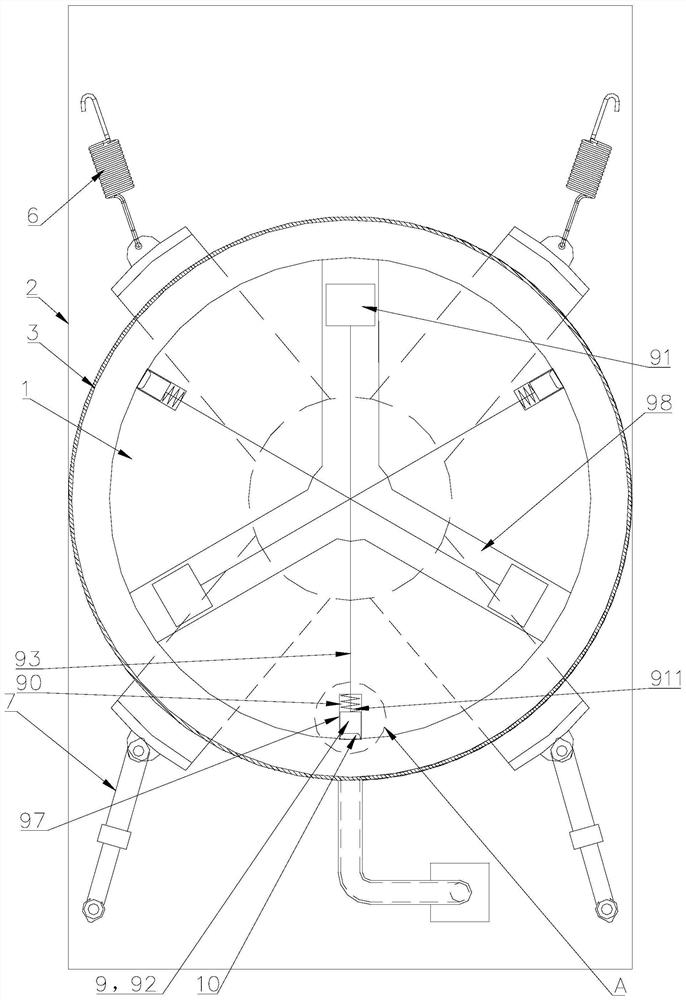

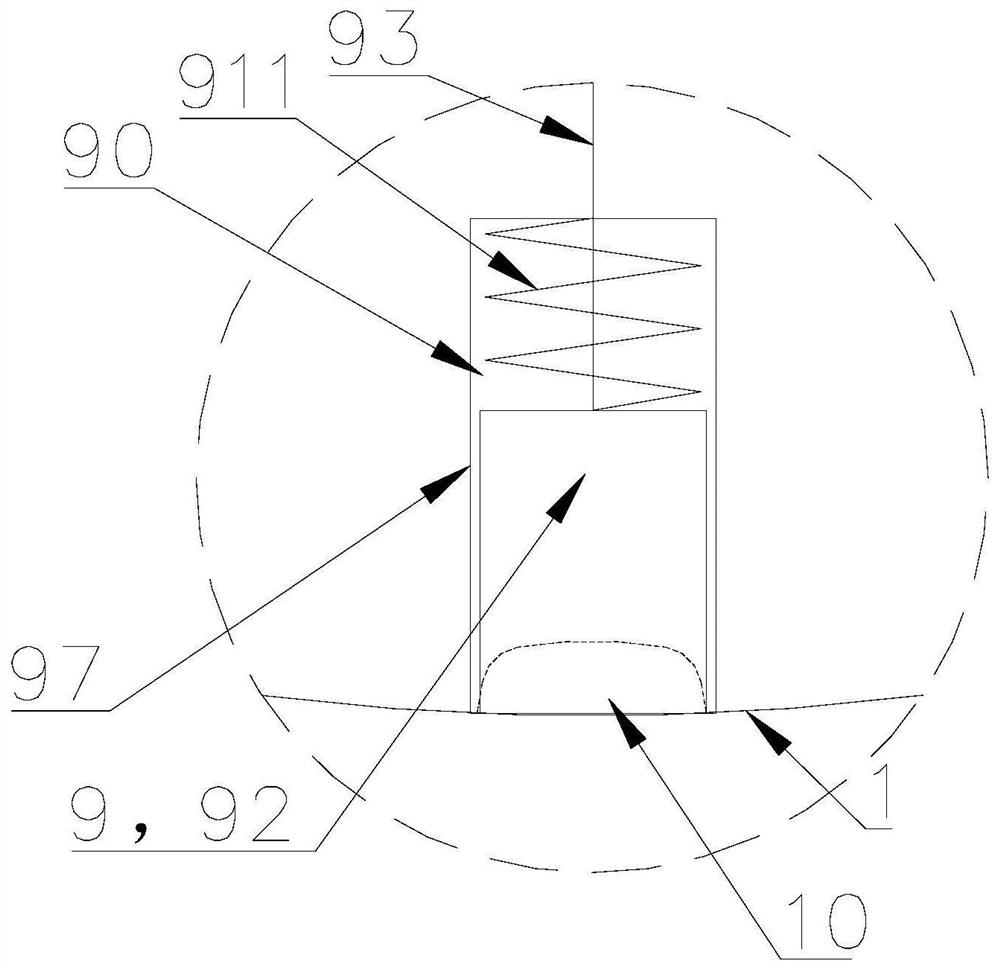

[0071] as Figures 5 through 7 As shown, the present embodiment introduces a washing machine, the washing machine inner cylinder 101 is a closed container after the door cover 4 is fastened, the bottom of the inner cylinder 102 has at least one drain 10, the drain port 10 is provided along the bottom of the inner cylinder 102 radially moving open and closed sealing valve 9, the valve body 92 of the sealing valve 9 when the inner cylinder 1 rotates at high speed is moved in the parallel plane of the inner cylinder bottom 102 under centrifugal force to open the drainage port 102 provided by the inner cylinder bottom 102.

[0072] In the present embodiment, the sealing valve 9 comprises a valve body 92 and ...

Embodiment 3

[0083]Embodiment of the present invention in order to remove the washing machine inner cylinder 1 after the clothing is separated from the water flow, and to achieve the washing machine work process of the inner cylinder 1 sealed water for normal washing, the following settings:

[0084] as Figures 8 through 10 As shown, the present embodiment introduces a washing machine, the washing machine inner cylinder 101 is a closed container after the inner cylinder mouth 101 is fastened by the door cover 4, the inner cylinder 1 side wall is provided with a plurality of lifting ribs 8, the lifting rib 8 is hollow and connected to the inner cylinder 1 internally, the inner cylinder 1 side wall is provided with at least one drain port connected to the hollow part of the lifting rib 8 10, the drainage port 10 is provided with a sealing valve 9 inside the lifting rib 8, the valve body 92 of the sealing valve 92 moves in the radial center direction of the inner cylinder 1 under the action of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com