A sealing valve spool structure and no-cleaning washing machine

A technology for sealing valves and spools, applied in the field of washing machines, which can solve problems such as inability to clean, easy accumulation of dirt, increased bacteria in washing machines, etc., achieving remarkable effects, clear design concepts, and simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

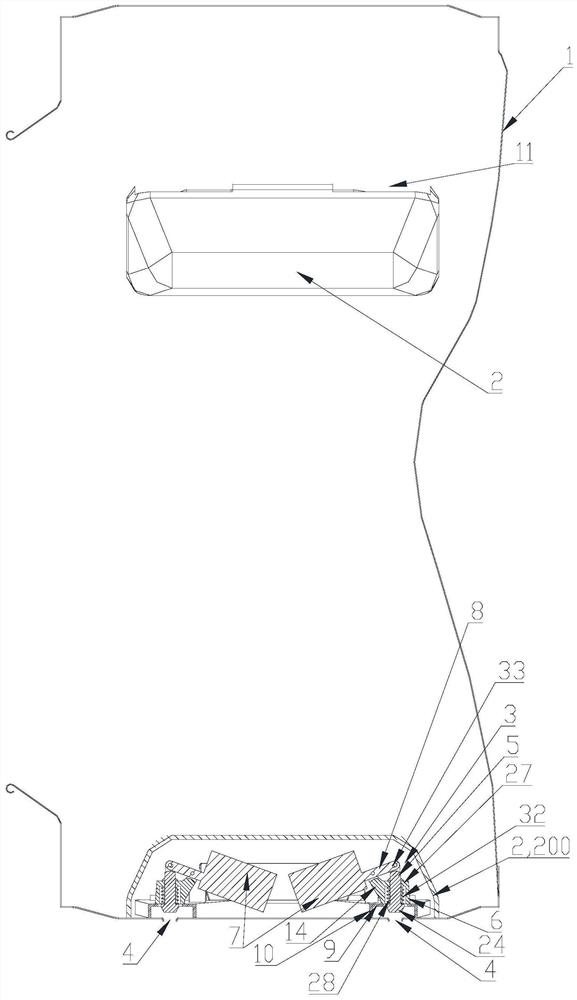

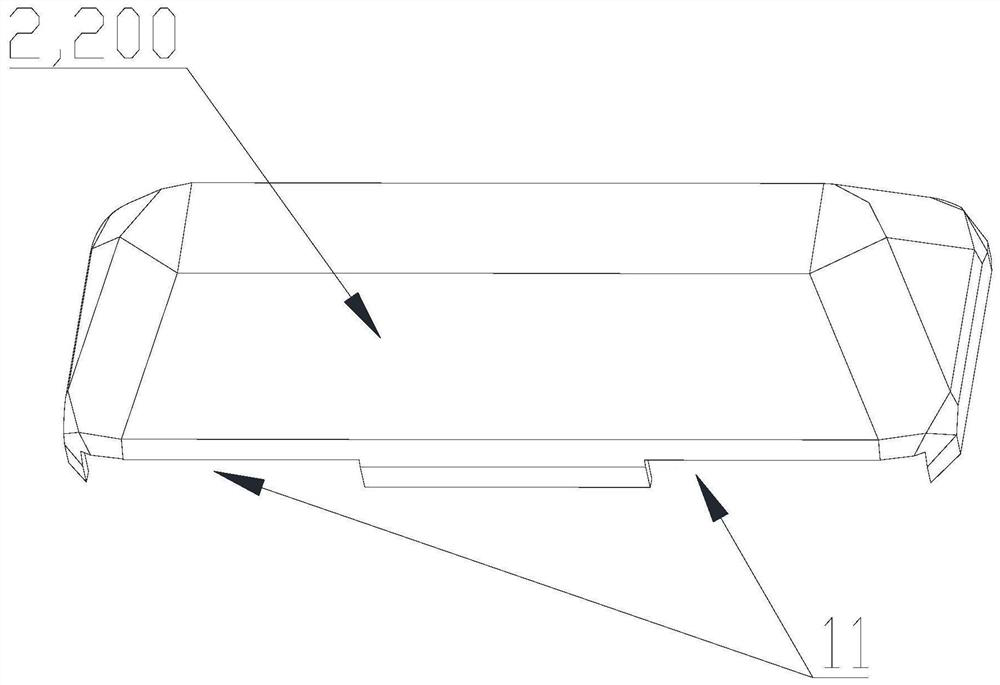

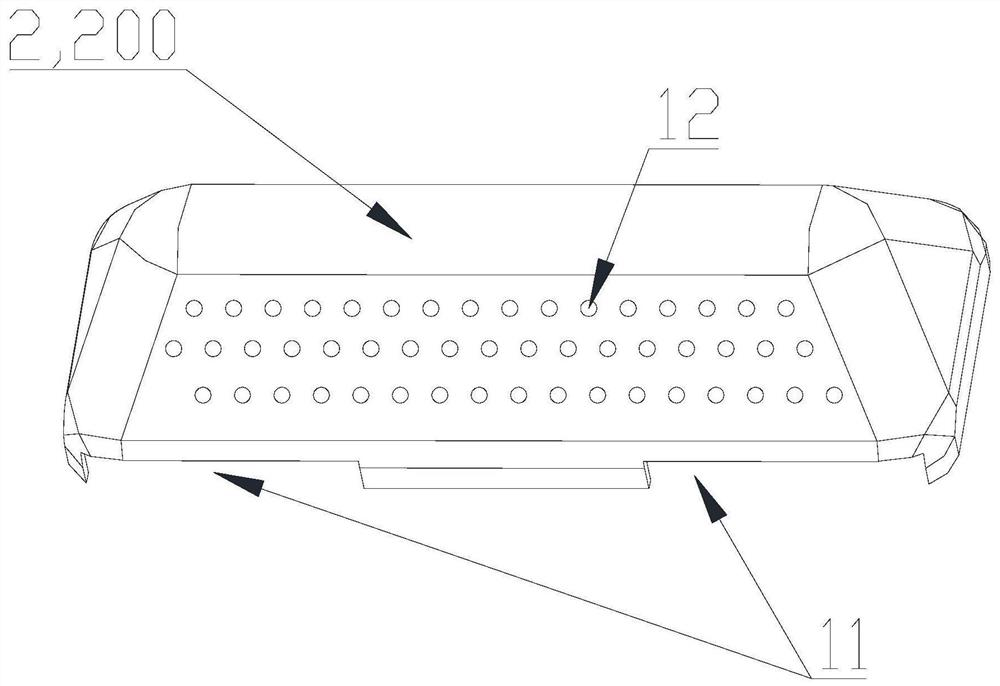

[0044] like Figure 1 to Figure 5 As shown, this embodiment introduces a lifting rib structure of the inner tube for the above-mentioned no-cleaning washing machine. The inner tube lifting rib 2 includes a lifting rib body 200 extending along the inner tube side wall construction line. The shell structure is open on the side and fastened to the inner wall of the inner cylinder 1. The interior of the lifting rib body 200 is hollow to form the installation cavity 3 for the installation of the sealing valve. into the water structure in the installation cavity 3.

[0045] By setting the lifting rib of the inner cylinder as a hollow chamber, the inside of the lifting rib forms a chamber for the installation of the water supply and drainage sealing valve, thereby achieving the concealed assembly of the sealing valve and realizing the function of the non-cleaning washing machine using centrifugal force to drain water; at the same time, the lifting The ribs extend along the construct...

Embodiment 2

[0059] like Figure 1 to Figure 7 As shown, this embodiment introduces a sealing valve installation structure for the above-mentioned no-cleaning washing machine. The sealing valve installation structure includes a support plate 9 installed on the inner wall of the inner cylinder 1. The middle part of the support plate 9 is provided with a The through hole 23 corresponding to the outlet 4 on the side wall of the cylinder 1, the support plate 9 and the side wall of the inner cylinder 1 are separated by a certain gap to form a space for the spool of the sealing valve to move up and down; the upper side of the support plate 9 is fixed A sleeve-shaped installation sleeve 6 is installed, and the inner through hole of the installation sleeve 6 is coaxially arranged opposite to the through hole 23 provided on the support plate 9, so that the spool of the sealing valve can be installed coaxially and movable up and down on the inner through hole. in the hole.

[0060] By setting the a...

Embodiment 3

[0071] like Figure 1 to Figure 7 As shown, in this embodiment, a sealing valve plug structure for the above-mentioned no-cleaning washing machine is introduced, and the sealing valve core structure includes a valve plug column 5 correspondingly installed on the drain port provided on the side wall of the inner cylinder 1, and A counterweight 7 hinged at the upper end of the valve plug post 5 ; a sealing valve installation structure is fixedly installed on the side wall of the inner tube 1 , and a return spring 32 is sandwiched between the sealing valve installation structure and the valve plug post 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com