Roller washing machine

A drum washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of poor assembly effect of the main control board and achieve good assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

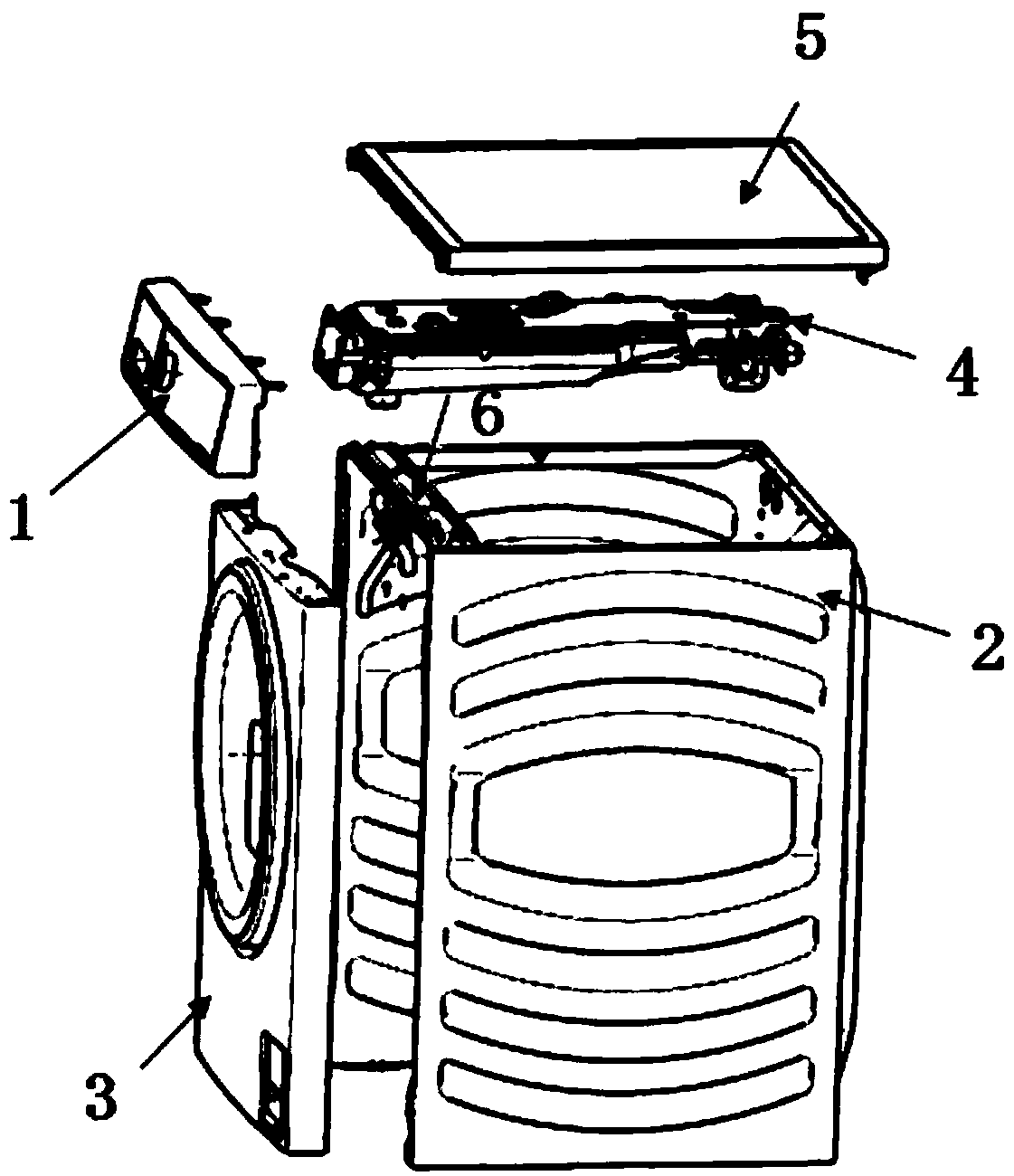

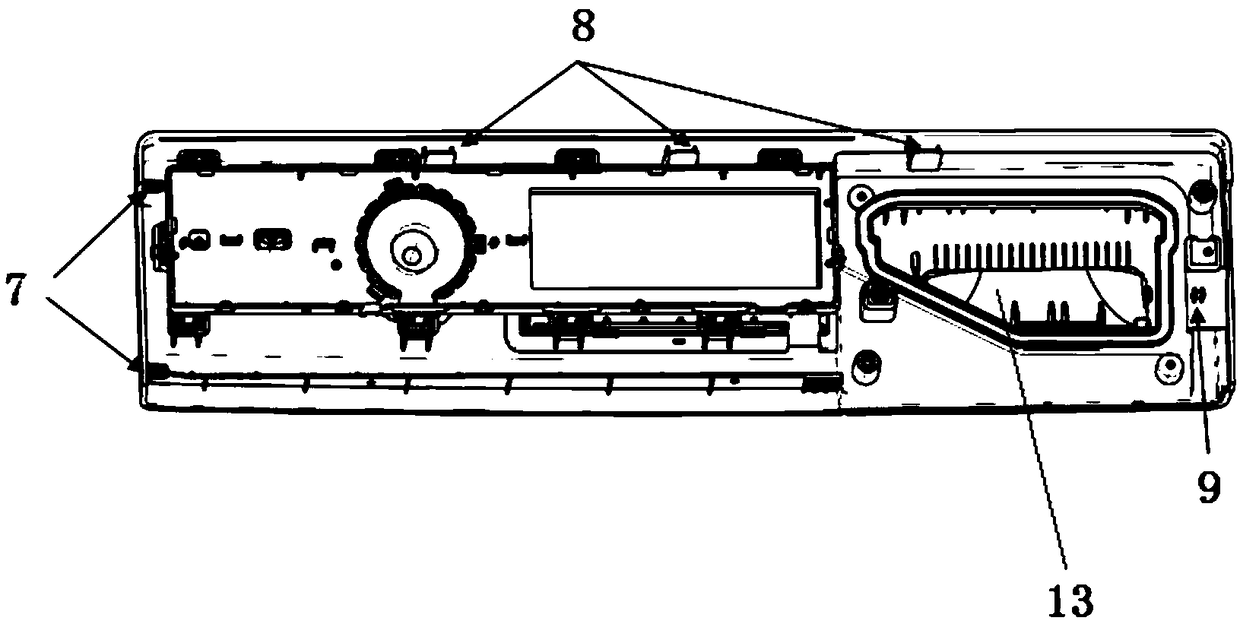

[0046] Such as Figure 4 , the clamping part in this embodiment is a buckle 7, and the box body 2 includes a crossbeam 6 located at the top of the washing machine. The end of the crossbeam 6 is correspondingly provided with a bayonet that cooperates with the buckle 7, and one end of the main control board 1 passes through the crossbeam 6. The cooperation between the buckle 7 and the card slot is connected with the box body 2, and the connection between the buckle 7 and the beam 6 is convenient for disassembly and installation, and this assembly method is relatively simple.

[0047] As a further alternative, the buckle 7 is integrally formed with the main control board 1, and the buckle 7 is bent inwardly in the horizontal direction on one end of the main control board 1. In this embodiment, the buckle 7 is in the height direction of the washing machine. There are two arranged side by side, but not limited to two, but also more, so that the connection between the main control b...

Embodiment 2

[0049] Such as Figure 2-5 As shown, the main control board 1 in this embodiment is a rectangle with two long sides and two short sides. On one end of the short side, two short sides of the main control board 1 are connected with the washing machine cabinet 2 , one long side of the main control board 1 is connected with the table top 5 , and the other long side is located on the top of the front board 3 .

[0050] The clamping part in this embodiment is a buckle 7, and the buckle 7 is arranged on a short side of the main control board 1. In this embodiment, there are two buckles 7, and the two buckles 7 are based on the main control board 1. The line of symmetry in the horizontal direction is centrally symmetrical, and the symmetrical setting of the buckle 7 is to ensure that the main control board 7 is evenly stressed in the longitudinal direction after installation. beautiful.

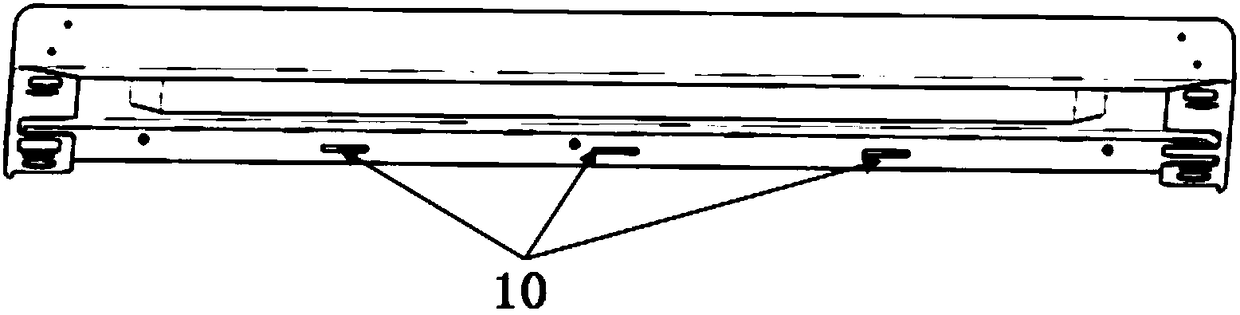

[0051] A limiting rib 11 for limiting the sliding of the main control board 1 is provided on th...

Embodiment 3

[0054] Such as figure 2 As shown, in this embodiment, a connector is provided on the other end of the main control board 1 on the basis of embodiment 1. The connector described in this embodiment is a screw 12 structure, and the other end of the main control board 1 and the beam Mounting holes are provided at the corresponding positions of 6, and screws 12 are fixedly connected to the main control board 1 and the box body 2 through the mounting holes. The main control board 1 of this embodiment is provided with a detergent box installation port 13 for installing a detergent box. The box installation port 13 is provided on the other end of the main control board 1 .

[0055] The mounting holes of the present embodiment are set to four, but not only limited to four but also more, the mounting holes are arranged on the periphery of the detergent box mounting port 13, such as figure 2 As shown, four installation holes are set on the four corners of the detergent box installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com