A plate conveying system applied to the cabinet plate production line

A technology of sheet production and conveying system, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of sheet backlog or long distance, affecting processing efficiency, and uncontrollable sheet distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The technical solution of the present invention will be more clearly described, and the present invention will be described below, which will be apparent from the accompanying drawings, and the drawings described below are merely an embodiment of the invention, and those of ordinary skill in the art, Other embodiments are obtained in accordance with this drawings and examples without paying creative labor.

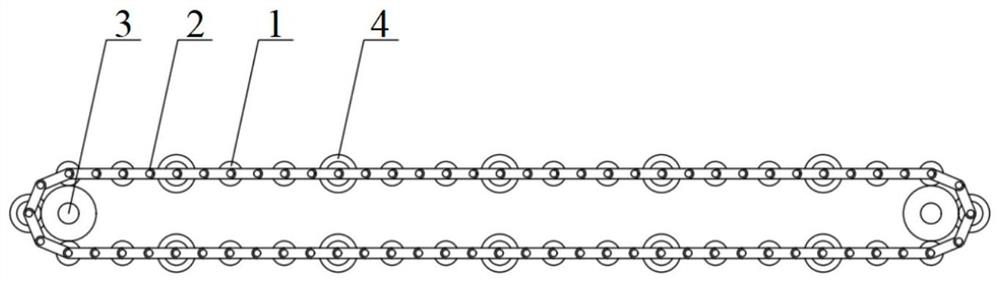

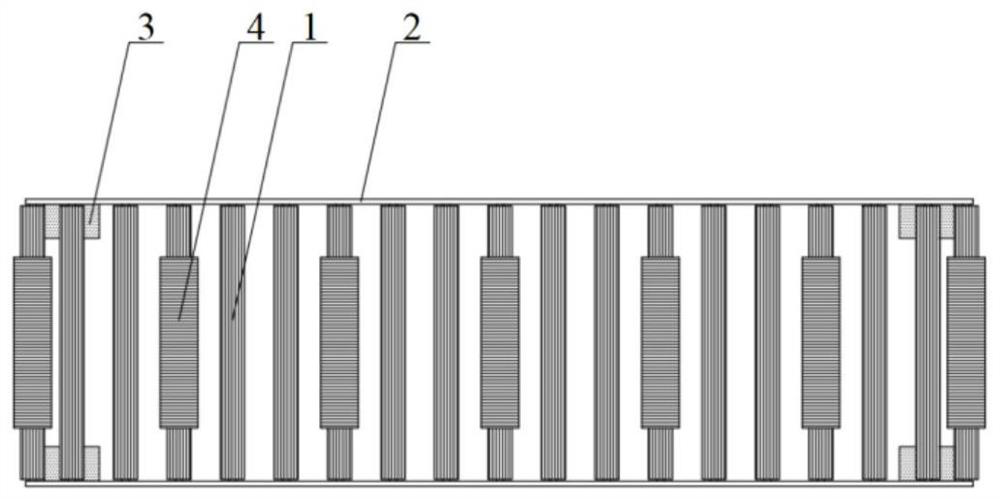

[0013]A sheet conveying system applied to the cabinet plate production flow line, such asfigure 1 withfigure 2As shown, a plurality of conveyor rollers 1 are included, and the conveying roller 1 is sequentially coupled to a closed ring, and the connecting member 2 is rotated between the conveying roller 1; the closed ring and the drive roller. 3 Match the delivery device; the drive roller 3 acts on the left and right ends of the closed circle and the intermediate is discontinuous; the transport roller 1 is actively provided with a brave sleeve 4, the plus coarse sleeve 4 In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com