Pet house and assembling element thereof

A pet house and assembly technology, applied in animal houses, synthetic resin layered products, layered products, etc., can solve problems such as low production efficiency, and achieve the effects of reducing strength, improving assembly efficiency, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

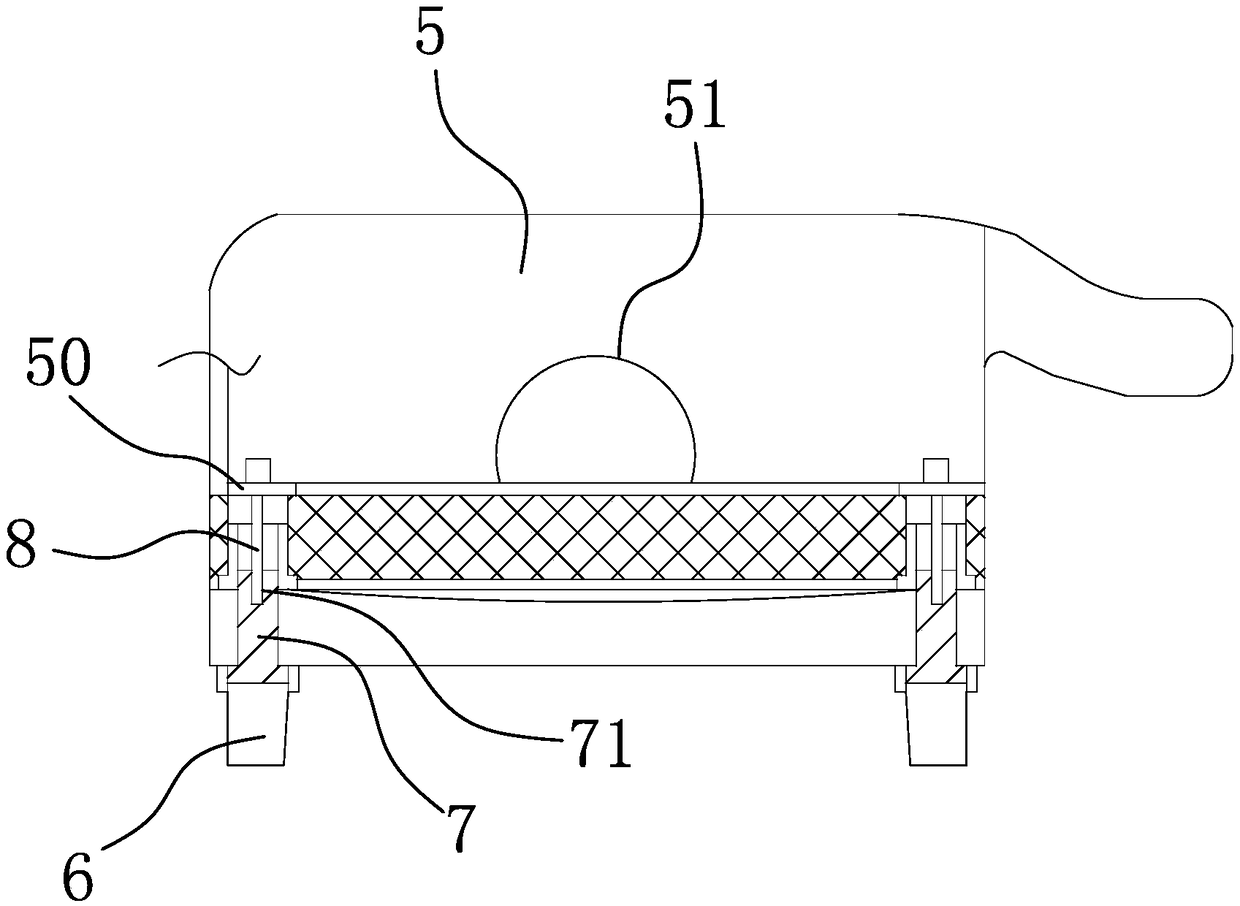

[0030] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

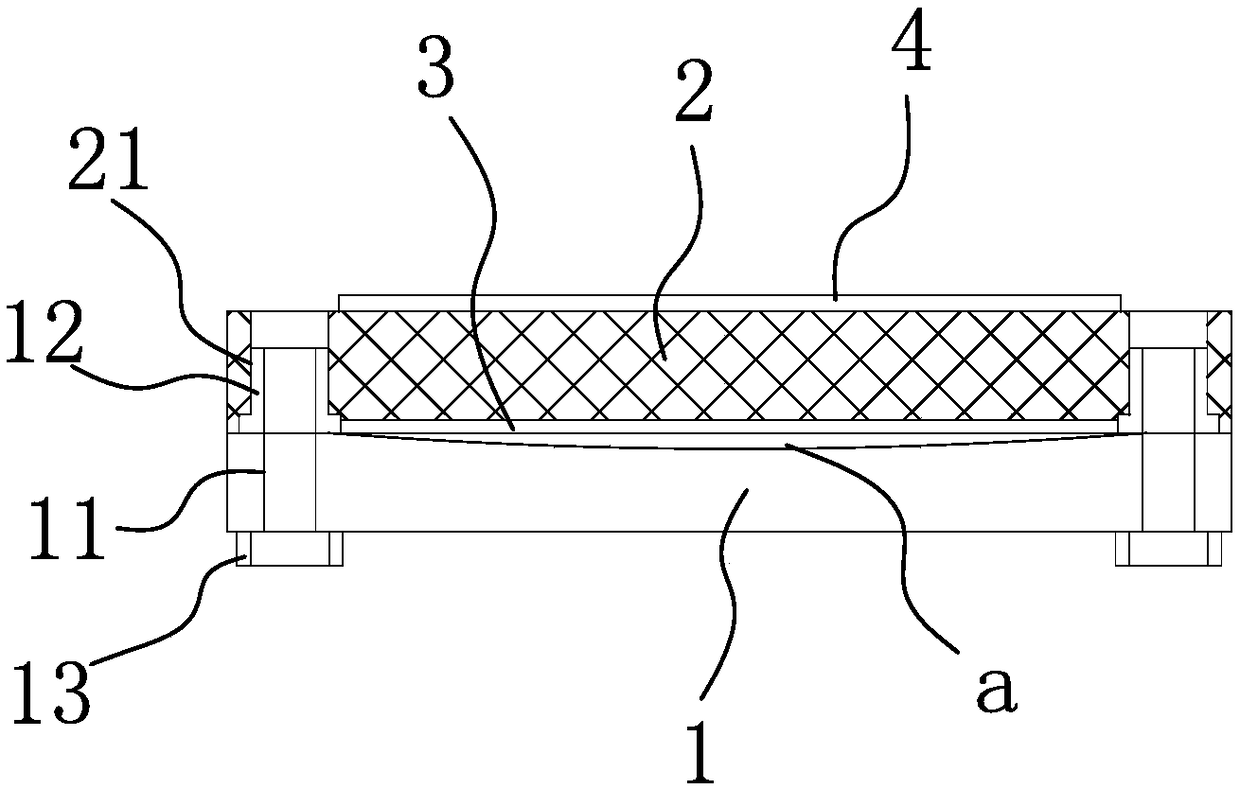

[0031] Such as figure 1 as shown,

[0032] The pet house assembly is arranged horizontally, including a wooden board 1, a sponge material layer 2 is arranged on the upper surface of the wooden board 1, and a plurality of through holes 11 are arranged around the upper surface of the wooden board 1, and are fixed on each through hole. The connecting sleeve 12 of the upper end opening of the hole 11 is provided with avoidance holes 21 for the connecting sleeves 12 to penetrate one by one on the sponge material layer 2 , and a film layer 3 is provided between the wooden board 1 and the sponge material layer 2 .

[0033] The lower end of the connecting sleeve 12 is provided with some pins, and the periphery of the upper end of the through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com