Split paper drawing roller bearing seat

A technology for bearing housings and paper pulling rollers, which is applied in the direction of bearing components, shafts and bearings, and rigid supports for bearing components. It can solve the problems of bearing housings and bearings being worn and loose, only downtime for maintenance, and increased replacement costs. Stability, reduced maintenance costs, improved installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

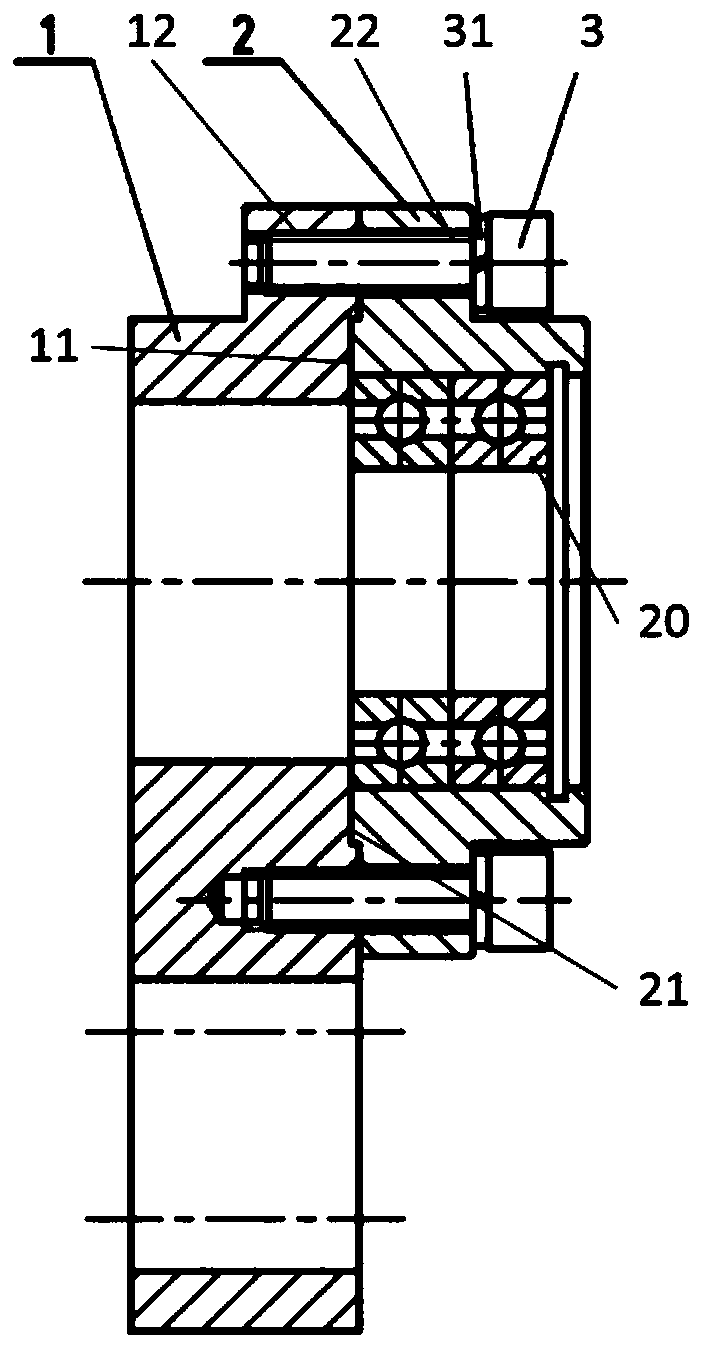

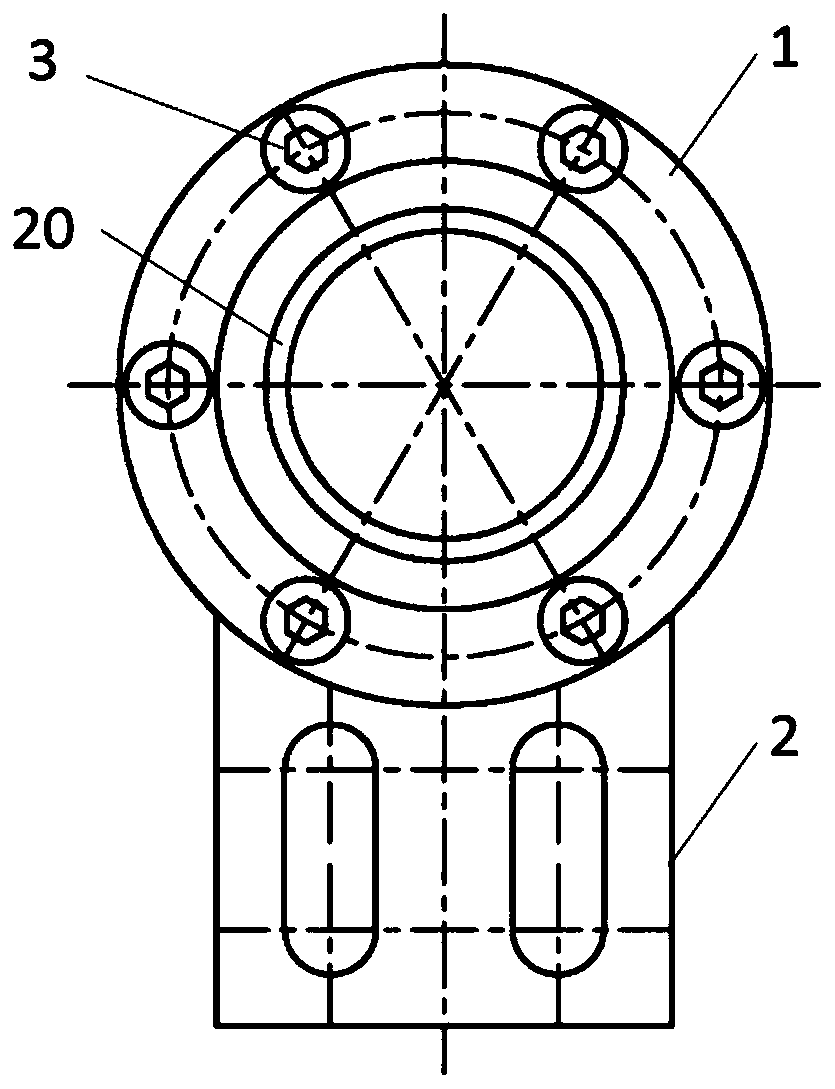

[0026] A kind of split type drawing roller bearing seat, such as Figure 1-2 , the bearing seat includes a bolt-connected bearing main seat 1 and a bearing sub-seat 2, the bearing main seat 1 is welded on the installation base plate, and the bearing 20 is installed in the bearing sub-seat 2. The material of the bearing sub-seat 2 is 40Cr steel or quenched and tempered 45# steel, and the high-strength material is beneficial to prolong the service life of the bearing seat.

[0027] The main bearing base 1 is provided with 6 bolt holes 12 . The bearing sub-seat 2 is provided with bolt through holes 22 matching the position and quantity of the bolt holes 12 . The bearing main seat 1 and the bearing sub-seat 2 are connected by six symmetrically arranged bolts 3 . A spring washer 31 is arranged between the bolt 3 and the bearing sub-seat 2, which can reduce the wear effect of the bolt 3 on the bearing sub-seat 2.

[0028] A circular groove 11 is provided on the bearing main seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com