Integrated automobile panel accessory opening forming die

A technology of hole forming and sheet metal, which is applied in the field of hole forming molds for integrated automobile sheet metal parts, can solve the problems of lower production efficiency, high stamping pressure, increase of operators, turnover boxes of semi-finished products of stamping equipment, and venues, so as to improve production efficiency , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

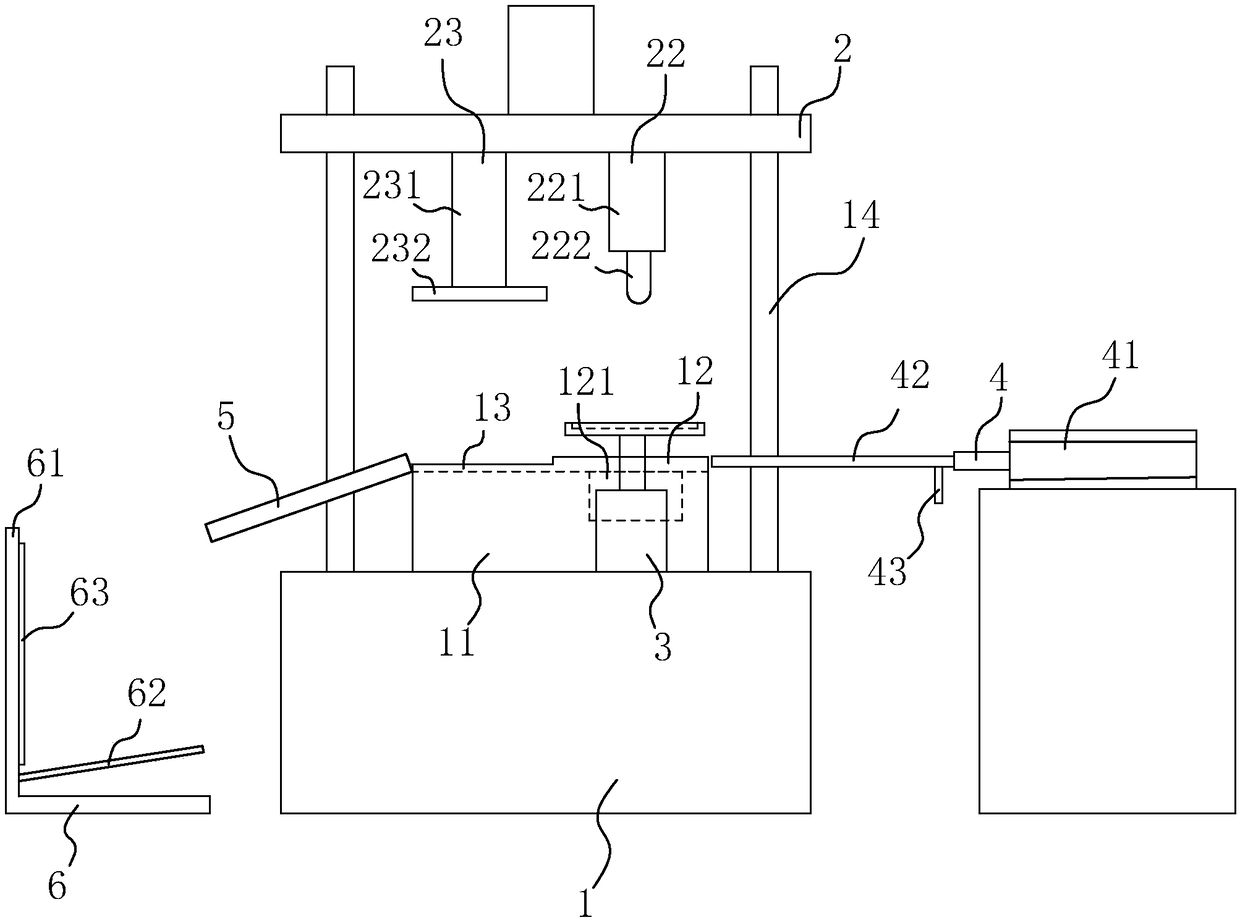

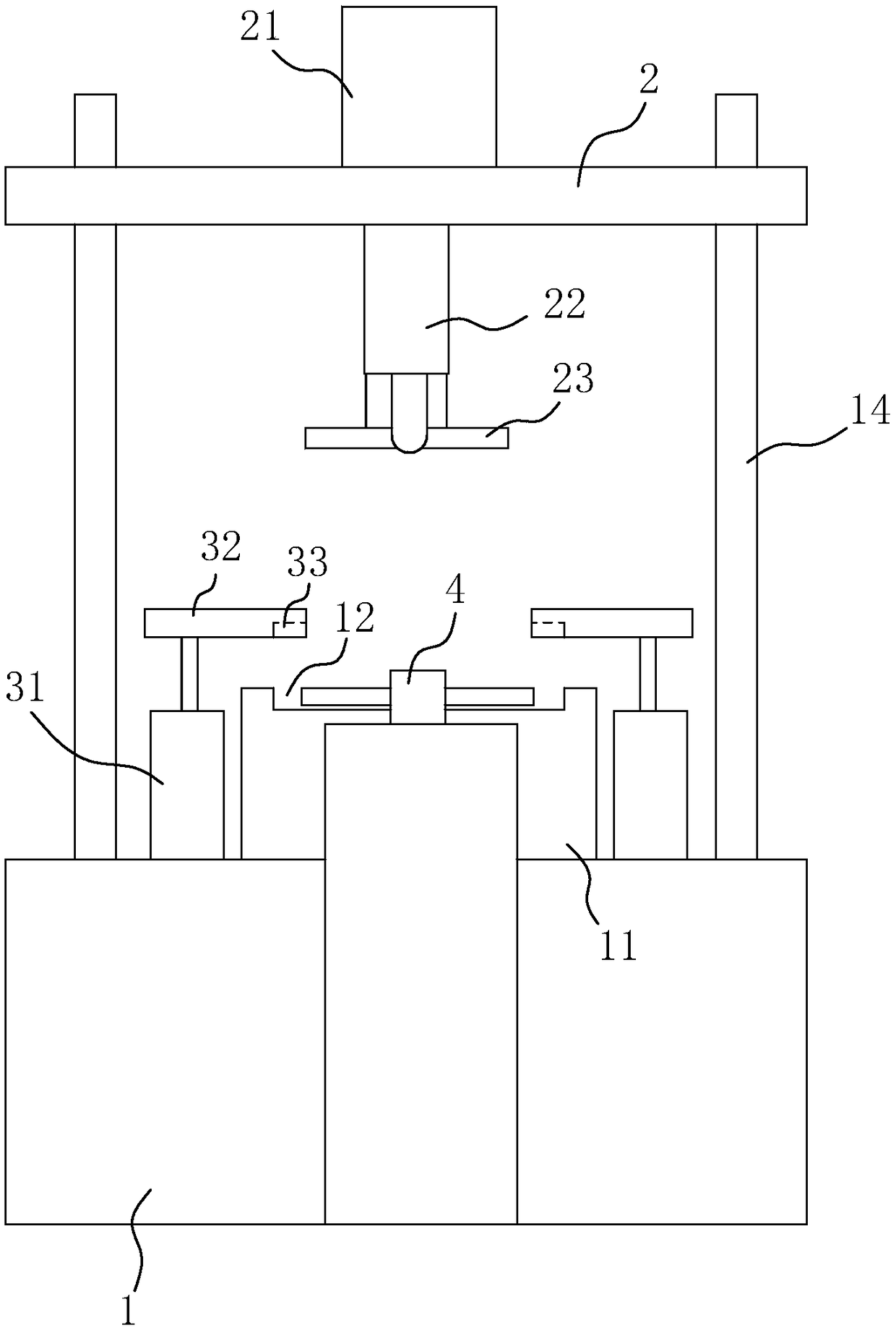

[0035] An integrated automobile plate accessories hole forming mold, such as figure 1 and figure 2 As shown, it includes: a lower mold base 1, a mold core 11 is provided on the lower mold base 1, a first mold cavity 12 and a second mold cavity 13 for accommodating the plate to be processed are opened on the mold core 11, the first mold cavity 12 One group of opposite sides is open, the second mold cavity 13 is connected with the first mold cavity 12 and the bottom walls of the two are flush, and the lower mold base 1 is provided with a guide rod 14; The upper mold base 2 of the rod 14, the upper mold base 2 is connected with the driving device 21, and the lower surface of the upper mold base 2 is provided with a punching assembly 22 at a position corresponding to the first die cavity 12, and is connected with the second mold A stamping assembly 23 is provided at a position corresponding to the cavity 13; a fixing assembly 3 carried on the lower mold base 1 for pressing and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com