3D (three-dimensional) glass with interlayer circuit and preparation method and application thereof

A glass and 3D technology, which is applied in the field of 3D glass with interlayer circuits and its preparation, can solve problems such as the difficulty of bonding antennas or coils to 3D glass, and achieve changeable industrial design, wide design freedom, and reduced process effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] The present invention solves the defects of difficulty in bonding antennas or coils to 3D glass, low yield, and high cost in the prior art, and proposes a process of welding conductive functional layers such as antennas or coils with two kinds of glass to obtain a new type of 3D glass. Circuit structure in glass, preparation method and application. Specifically, the embodiment of the present invention discloses a 3D glass with an interlayer circuit and its preparation method and application.

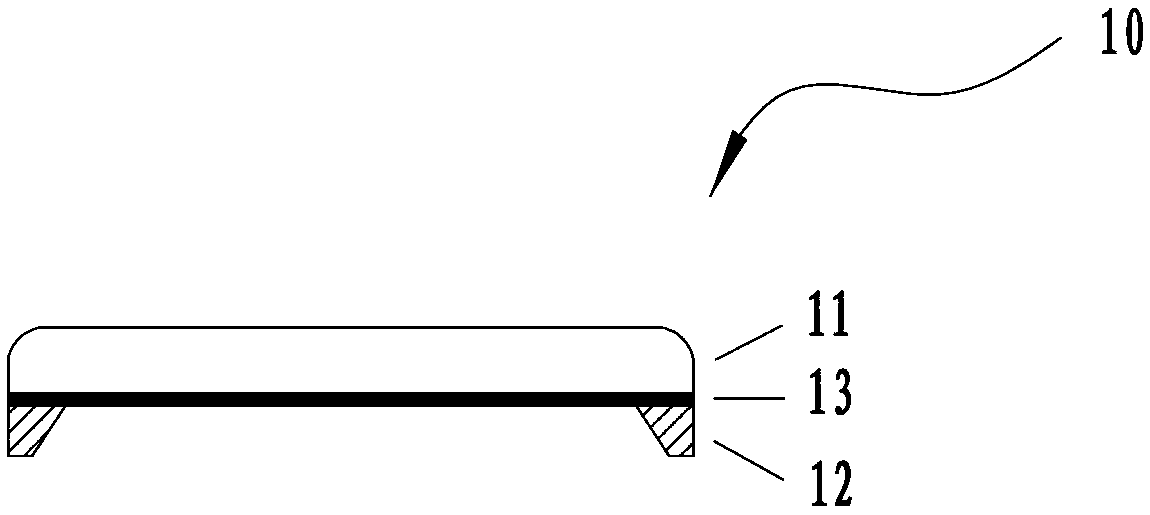

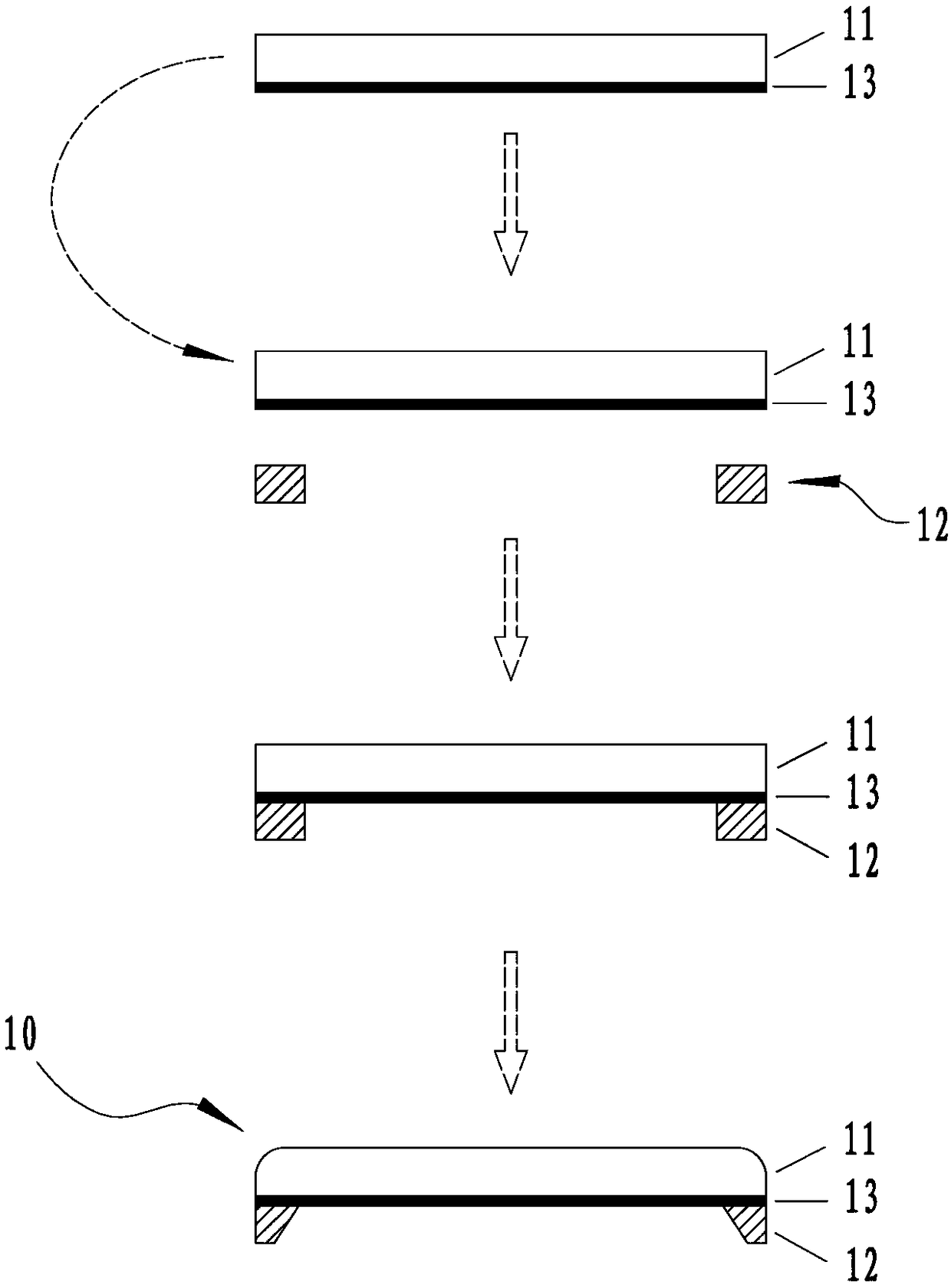

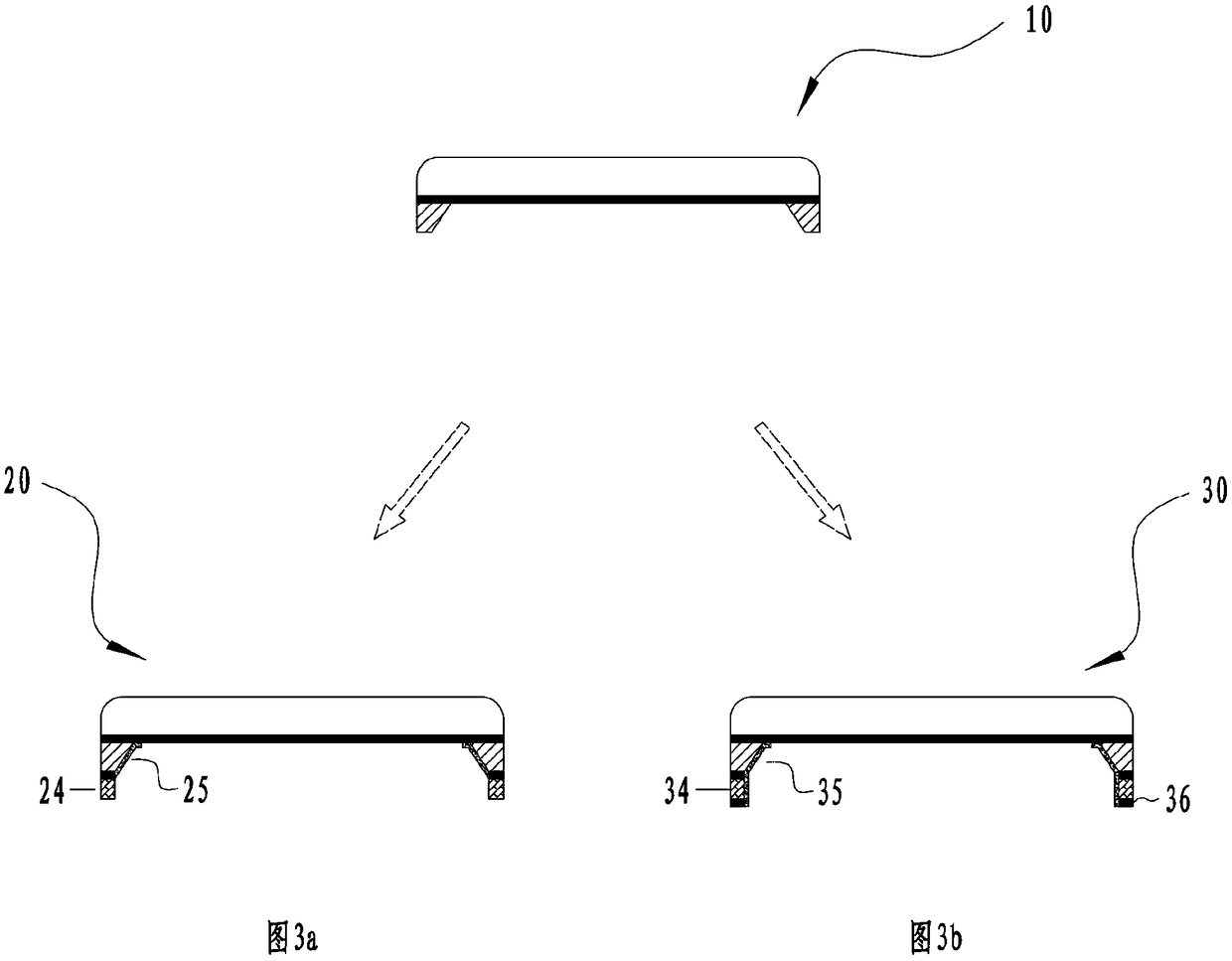

[0030] Please combine the following Figure 1-3 , the embodiment of the present invention first provides a 3D glass 10 with an interlayer circuit, which includes a first glass 11, a second glass 12, and a conductive functional layer 13 disposed therebetween, and the conductive functional layer can be formed on the first glass or one side of the second gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com