Detection device and method for effective filter scanning table frame scanning

A high-efficiency filter and detection device technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of leakage in the vertical gap of the filter frame, energy waste, and accuracy cannot be guaranteed, and achieve the isolation of external air , detection of accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

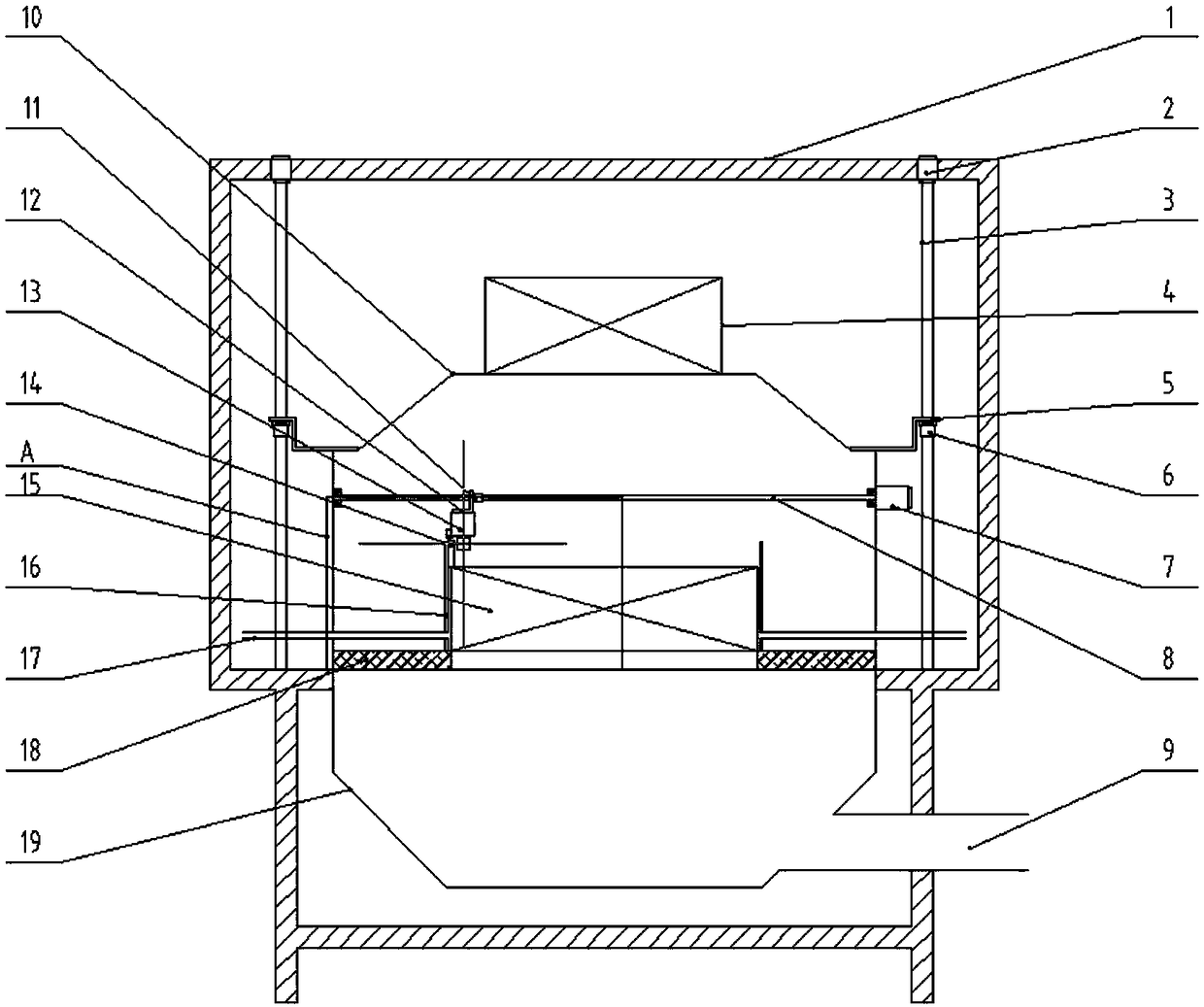

[0044] as attached figure 1 To attach Figure 5 As shown, the present invention is a detection device for scanning the frame of a high-efficiency filter scanning table, including a frame 1, a filter test fixture 18, a sampling head, a displacement drive mechanism, a controller, and an airflow anti-interference device.

[0045] In this embodiment, the filter test jig 18 is installed on the frame 1 to fix the filter 15 to be tested. Filters of different sizes match different sizes of jigs, and the frame 1 provides structural support.

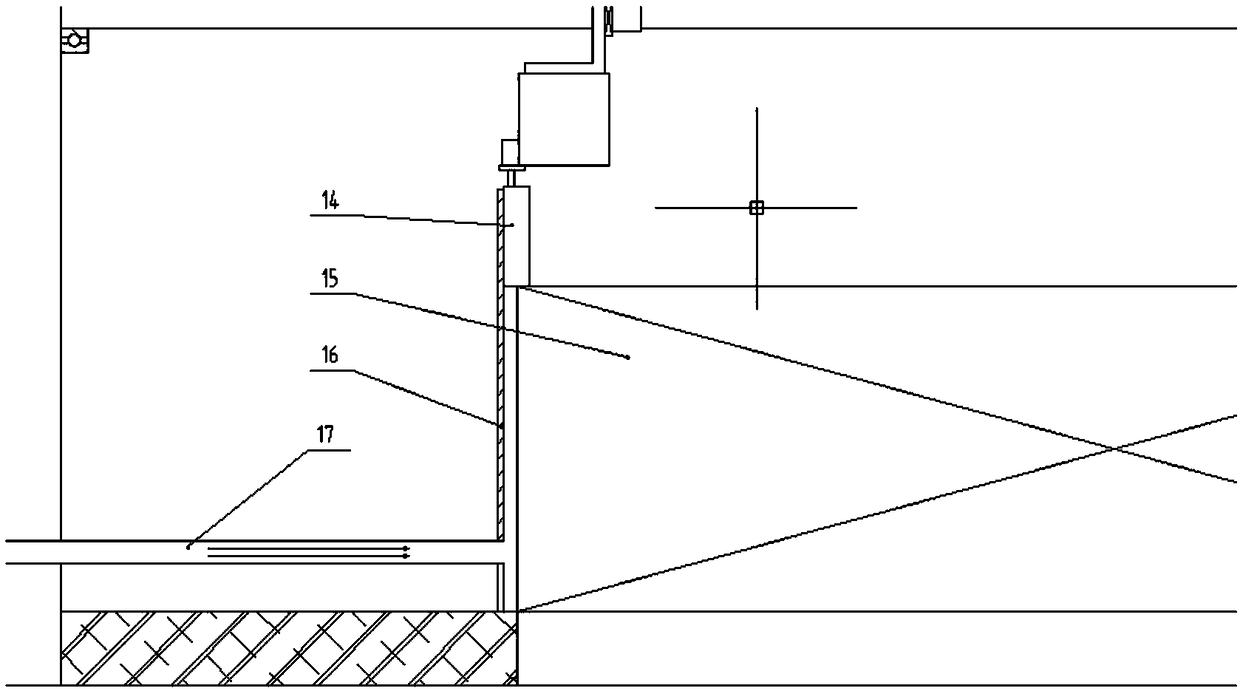

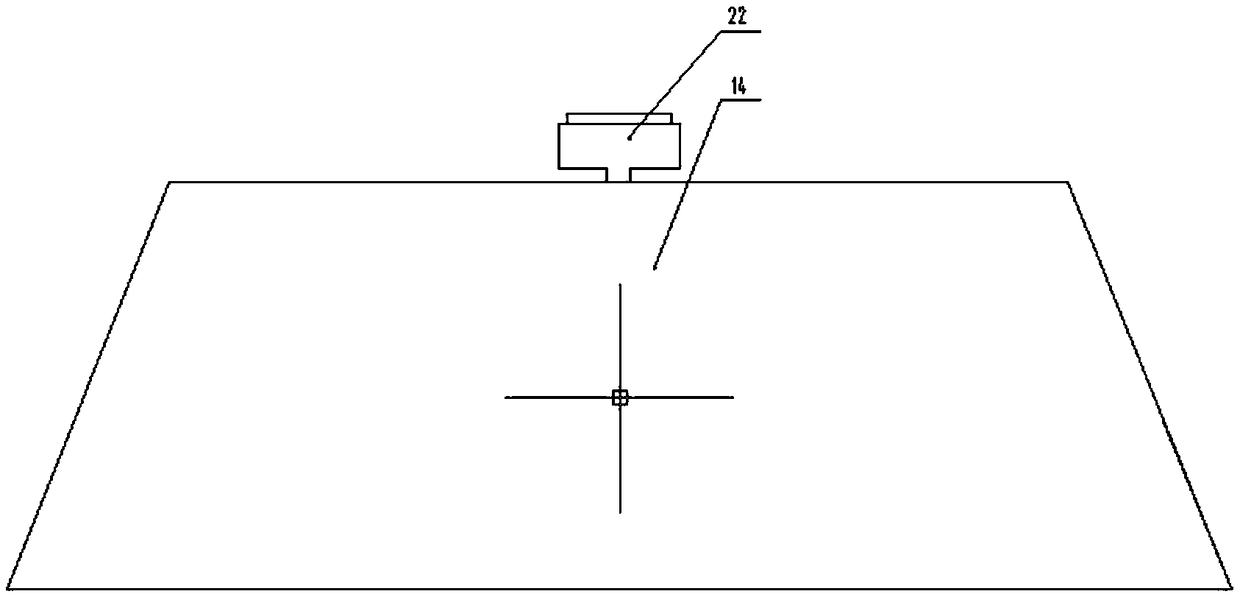

[0046] In this embodiment, in order to ensure that the sampling head can take particles on the frame, the sampling head is a rotatable sampling head 14, including a sampling head body and a rotary cylinder 22 that drives its rotation, for the frame and body of the filter 15 to be tested. For scanning, the particle concentration at the designated position of the frame is taken. In order to improve the scanning efficiency and increase the accuracy ...

Embodiment 2

[0056] as attached Image 6 To attach Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the distance between the isolation baffle and the frame is 10 mm, that is, the distance between the isolation baffle and the frame is equal to the width of the sampling head, and the rest of the structure is the same as that of Embodiment 1.

[0057] This embodiment is set up like this. When scanning the frame, the projected area of the sampling head can completely fall between the isolation baffle and the outer edge of the frame. If there is leakage at this time, it can be determined that it is an attached Figure 5 The frame vertical gap 20b of the frame of the filter to be tested leaks, and when the sampling head completely covers the frame of the filter to be tested and there is leakage, it is determined that the attached Figure 5 The frame plane gap 20a of the filter frame to be tested leaks, further distinguishing the leakage of the plane gap and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com