Turnover pressure boosting shower

A shower and panel technology, applied in spraying devices, spraying devices, etc., can solve the problems of small water spray holes, troublesome cleaning of water spray holes, clogging of impurities in water, etc., and achieve good anti-blocking holes, low production cost, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

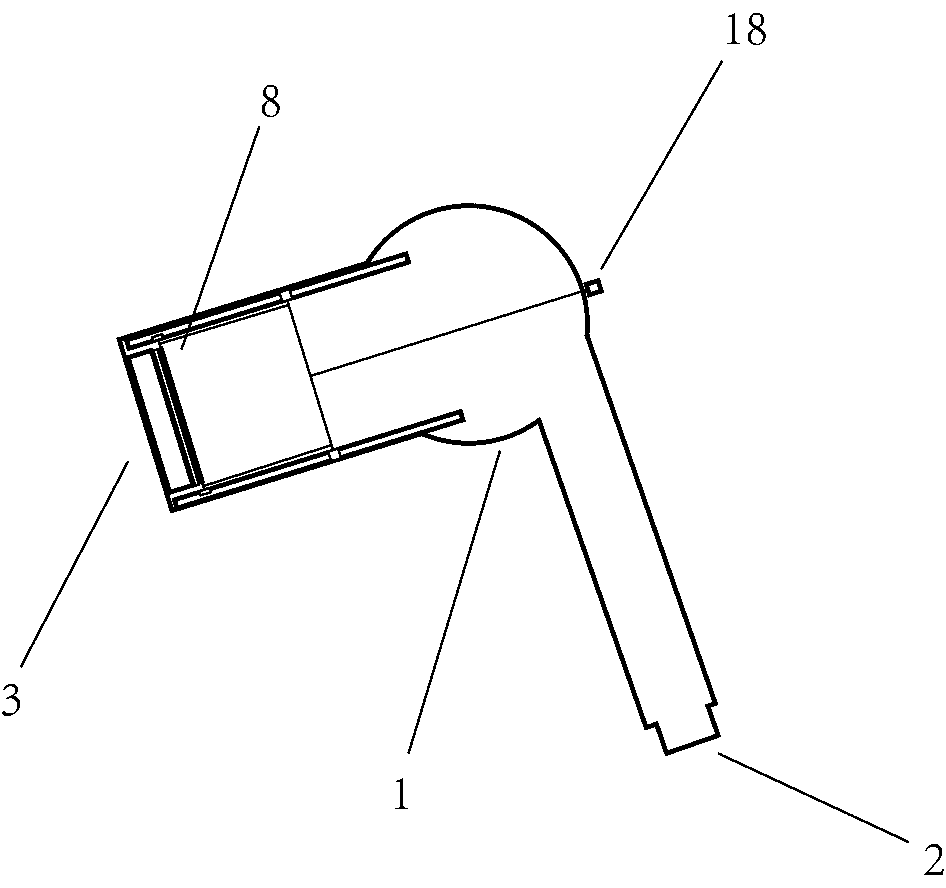

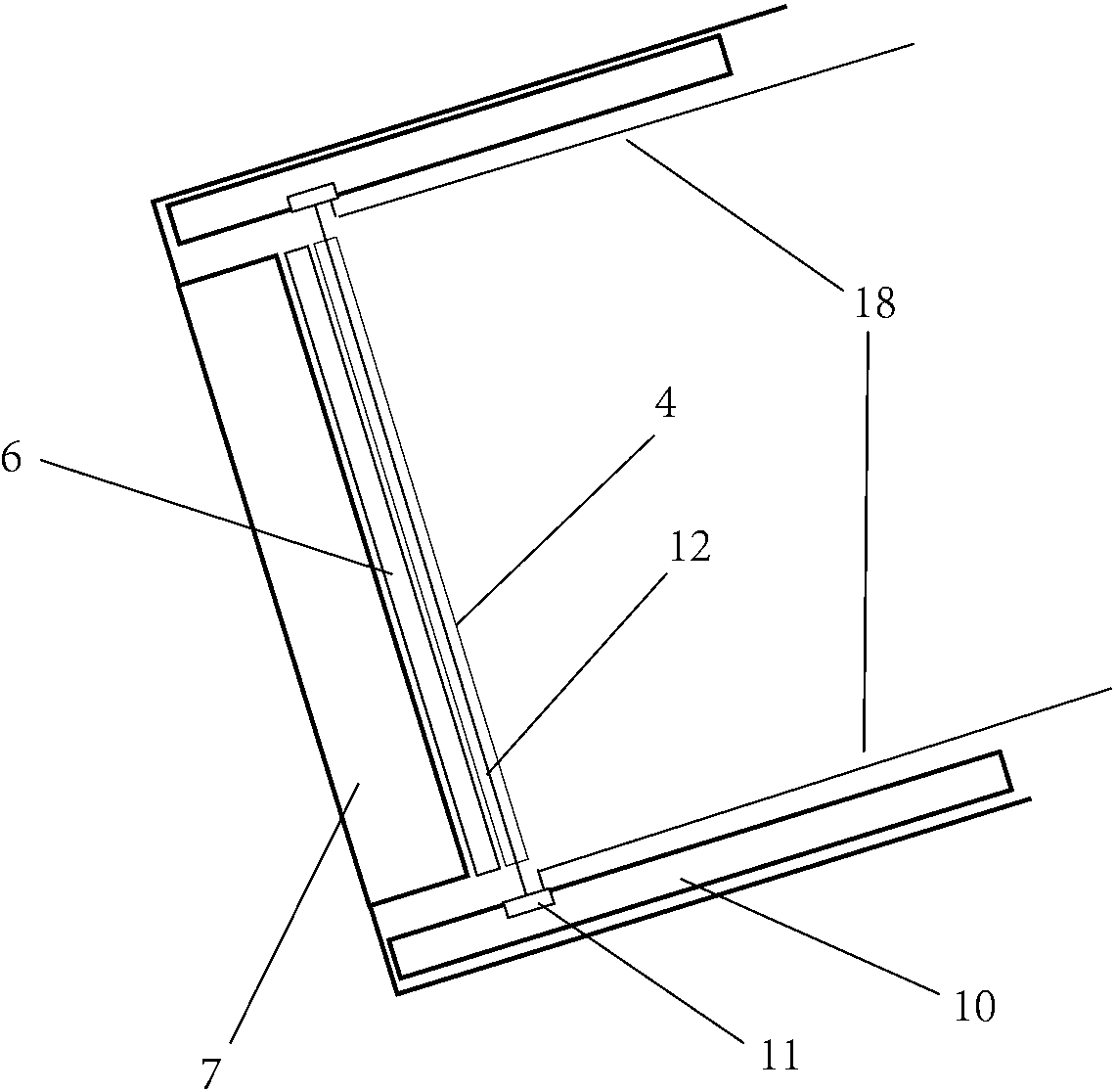

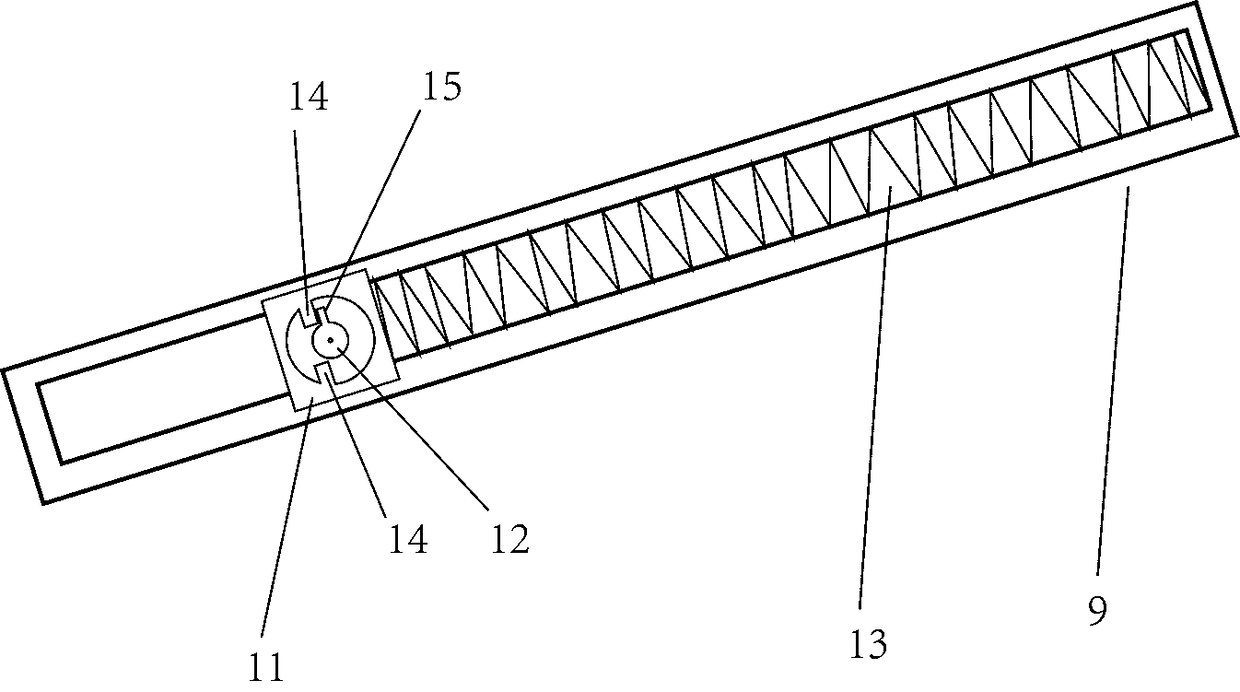

[0021] Embodiment 1: A reverse pressurized shower head, comprising: a casing 1, a water inlet 2, a water spray port 3, a panel 4, a fine hole 5, a sealing ring 6, a panel fixing ring 7 and a turning mechanism 8, the described The water inlet 2 is used for shower water intake, and the water spray port 3 is used for shower water outlet. The panel fixing ring 7 is arranged at the water spray port 3, and the panel 4 is placed inside the panel fixing ring 7 of the water spray port 3. A sealing ring 6 is arranged between the panel fixing ring 7 and the panel 4, and a fine hole 5 is arranged on the panel 4, and the fine hole 5 penetrates the panel 4, and the two sides of the panel 4 are penetrated, and the turning mechanism 8 can quickly turn over the panel 4, and the front of the panel 4 and the The reverse side of the panel faces outside the water spout 3 in turn, the water spout 3 is a rectangle, the panel 4 is a rectangle, a shaft 12 is arranged along the center of the panel 4, an...

Embodiment 2

[0026] Embodiment 2: A reverse pressurized shower head, including: a casing 1, a water inlet 2, a water spray port 3, a panel 4, a fine hole 5, a sealing ring 6, a panel fixing ring 7 and a turning mechanism 8, the described The water inlet 2 is used for shower water intake, and the water spray port 3 is used for shower water outlet. The panel fixing ring 7 is arranged at the water spray port 3, and the panel 4 is placed inside the panel fixing ring 7 of the water spray port 3. A sealing ring 6 is arranged between the panel fixing ring 7 and the panel 4, and a fine hole 5 is arranged on the panel 4, and the fine hole 5 penetrates the panel 4, and the two sides of the panel 4 are penetrated, and the turning mechanism 8 can quickly turn over the panel 4, and the front of the panel 4 and the The reverse side of the panel faces outside the water spout 3 in turn, the water spout 3 is a rectangle, the panel 4 is a rectangle, a shaft 12 is arranged along the center of the panel 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com