Sewage disposal mechanism with good anti-blocking effect for sewage disposal

A technology of sewage treatment and sewage discharge mechanism, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc. It can solve problems such as difficult cleaning, blockage of sewage outlets, and inability to discharge residual bait in time, and achieves good anti-blocking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

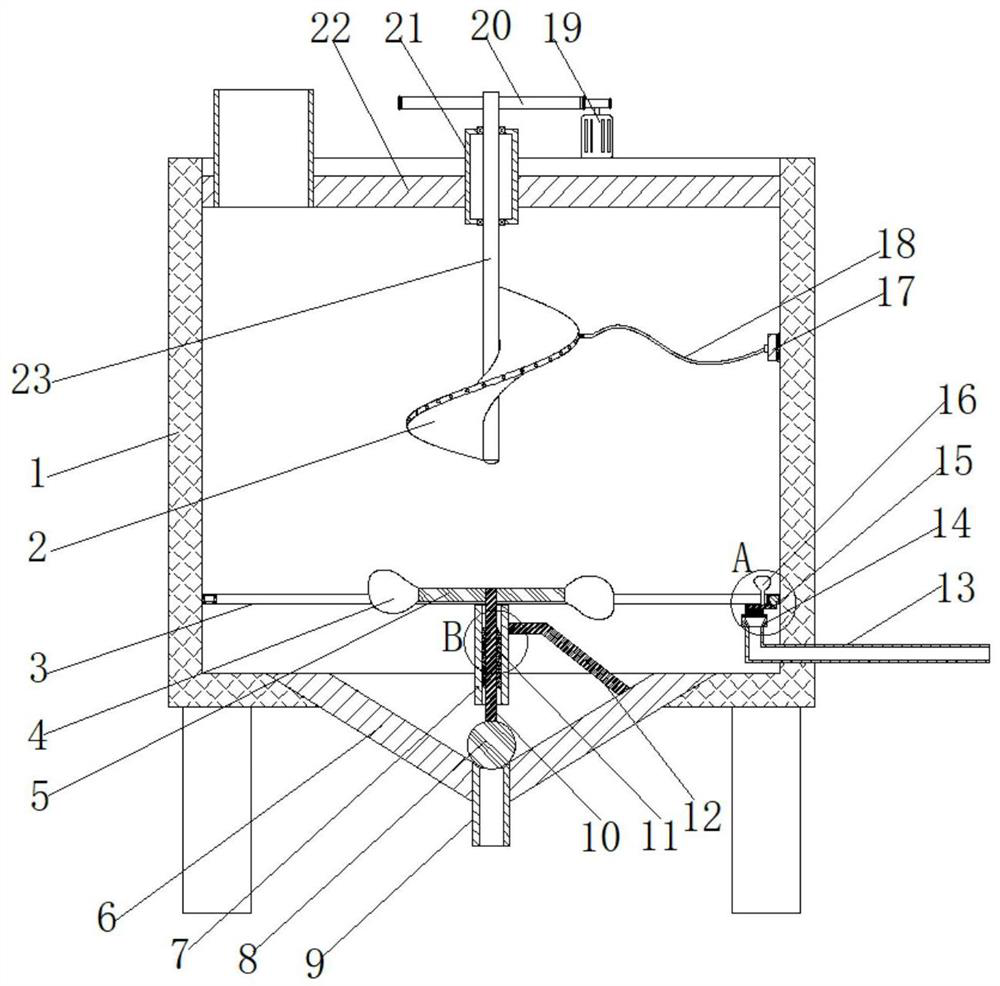

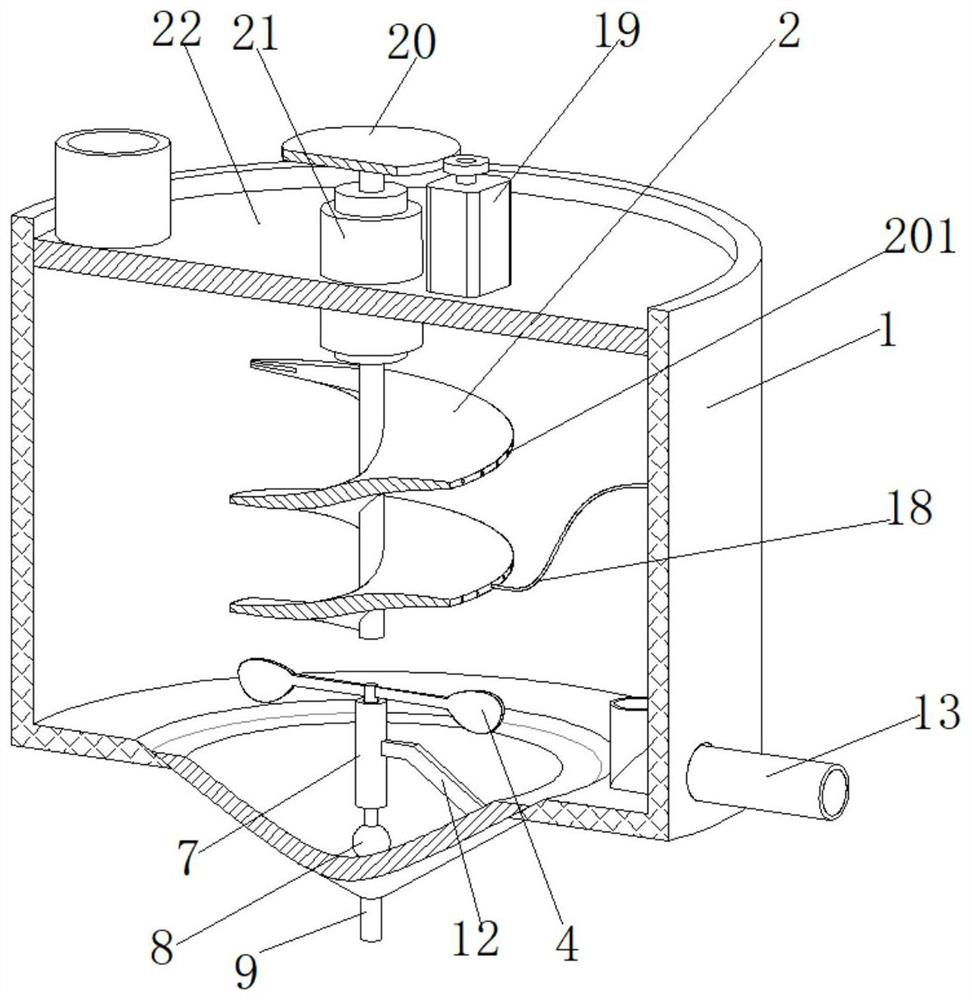

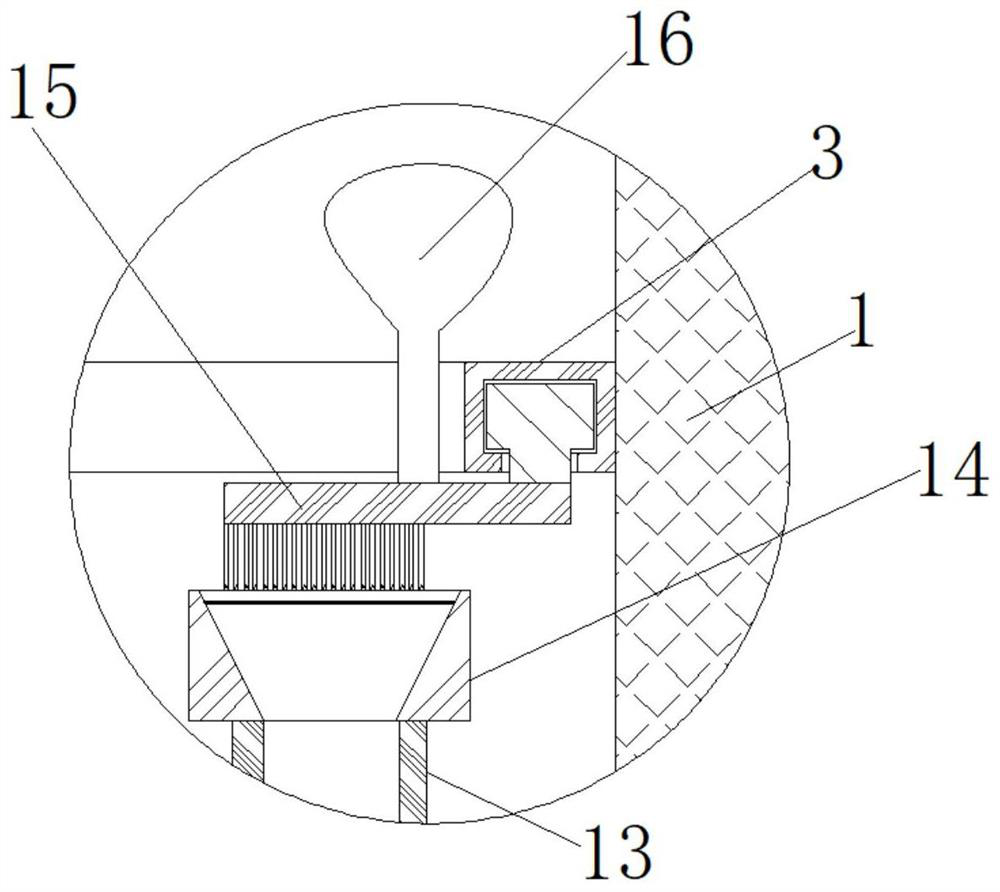

[0030] refer to Figure 1-5 A sewage discharge mechanism with good anti-blocking effect for sewage treatment, comprising a treatment barrel 1 with a cylindrical structure with a cavity inside, and a drainage pipe 13 in an L-shaped structure inserted into the outer wall of the treatment barrel 1 near the bottom end, the drainage pipe The opening of 13 faces directly above, and the top opening of the drain pipe 13 is sleeved with a filter head 14, the top of the filter head 14 is fixed with a filter screen, and the circumferential inner wall of the processing barrel 1 is fixed with an opening near the bottom end, and the downward section is C-shaped. The structure of the ring slide rail 3, and a T-shaped slider is slidably connected in the chute of the ring slide rail 3, and the lower surface of the T-shaped slider is fixed with a brush plate 15, and the bristles on the lower surface of the brush plate 15 and the surface of the filter screen In contact, the upper surface of the ...

Embodiment 2

[0041] refer to figure 1 and Figure 4 , a sewage discharge mechanism with good anti-blocking effect for sewage treatment. Compared with Embodiment 1, this embodiment also includes a driven gear 20 fixed near the top of the circumference outer wall of the transmission rod 23, and a fixed top of the top plate 22 near the middle. Servomotor 19, the top of the output shaft of servomotor 19 is fixed with the driving gear that meshes with the driven gear 20, so that when the inner wall of the processing barrel 1 needs to be cleaned during use, only the bent rod 18 needs to be bent to make the brush head 17 Just close to the inner wall of the processing barrel 1, and then start the servo motor 19 to allow the brush head 17 to brush on the inner wall of the processing barrel 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com