A power supply topology and control method for high-speed railway system over-phase separation

A topology, high-speed railway technology, applied in power lines, circuit devices, electrical components, etc., can solve problems such as unbalance, restrict safe and reliable operation, and exceed standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

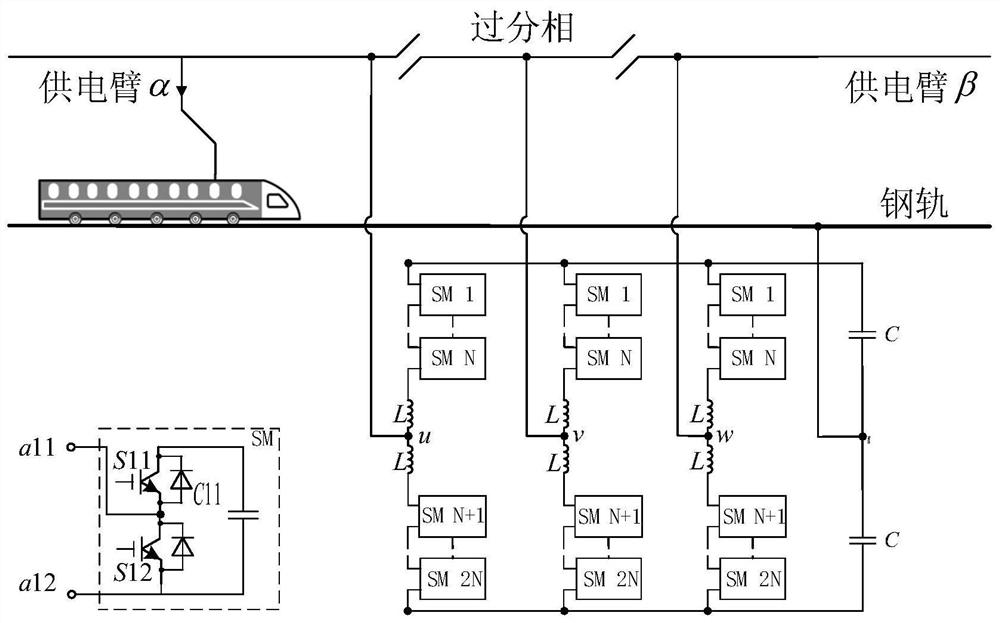

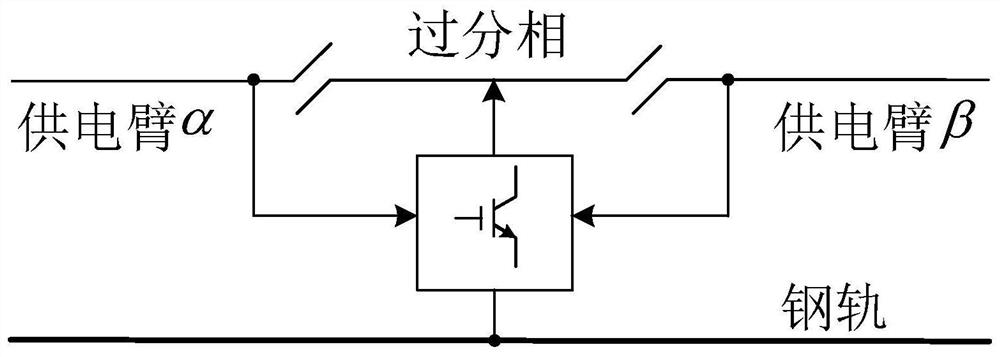

[0017] This embodiment is realized through the following technical solutions, as figure 1 As shown, a power supply topology for high-speed railway system with over-phase separation is u, v, w three-phase multi-level converter module branch, and each phase multi-level converter module branch is divided into upper bridge arm and the lower bridge arm, the upper bridge arm and the lower bridge arm of the u, v, w three-phase multi-level converter module branches are respectively composed of n multi-level converter modules MMC and a buffer inductor, The bridge arm and the lower bridge arm are respectively composed of n capacitor modules, and n is a positive integer greater than 1; wherein, the second interface a12 of the first multilevel converter module MMC1 is connected to the second interface a12 of the second multilevel converter module MMC2 The n multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com