Material conveying lifting device for civil engineering

A technology of civil engineering and lifting devices, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of no shock absorbing device and material falling down, and achieve the effect of increasing the storage space and improving the transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

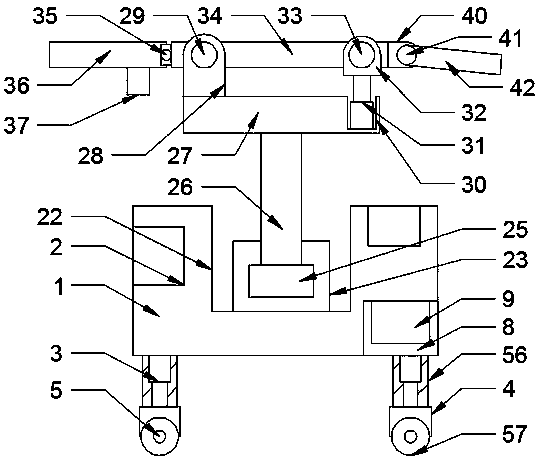

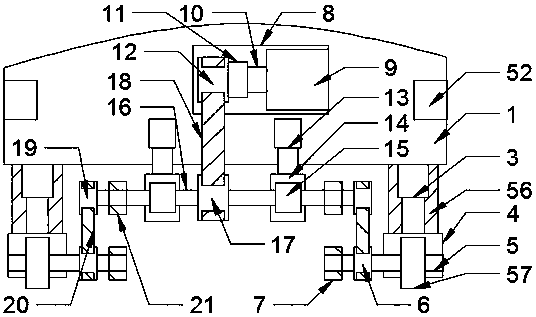

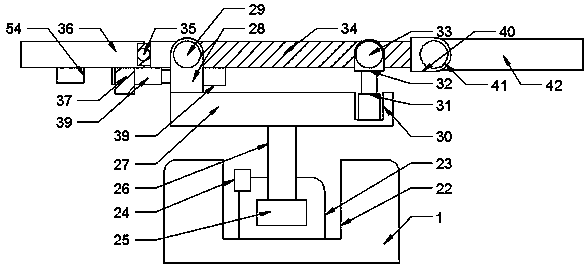

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 shown.

[0022] In this embodiment, in the first step, when transporting materials, touch the placement key on the controller 2, the two-way solenoid valve 24 is activated, the piston 25 moves downward in the hydraulic cylinder 23, and the piston 25 drives the lifting column 26 to move downward, The lifting column 26 drives the lifting and fixing plate 27 and the fixed placing plate 34 to move downwards. It is convenient to place materials, and materials can be placed at different heights, saving time and effort. Growth board 36, when level sensor 54 senses that placement growth board 36 is in horizontal position, hydraulic telescopic rod two 38 starts, and the telescopic end of hydraulic telescopic rod two 38 stretches in and drives fixed clamping rod 39 to move, and fixed clamping rod 39 is moved to the fixed position. The growth plate 36 is fixedly placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com