A mechanical performance test equipment for electrical safety tools

A technology for electrical safety and testing equipment, applied in the direction of using stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve the problems of high use cost, complex structure, single function, etc. Small cost, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

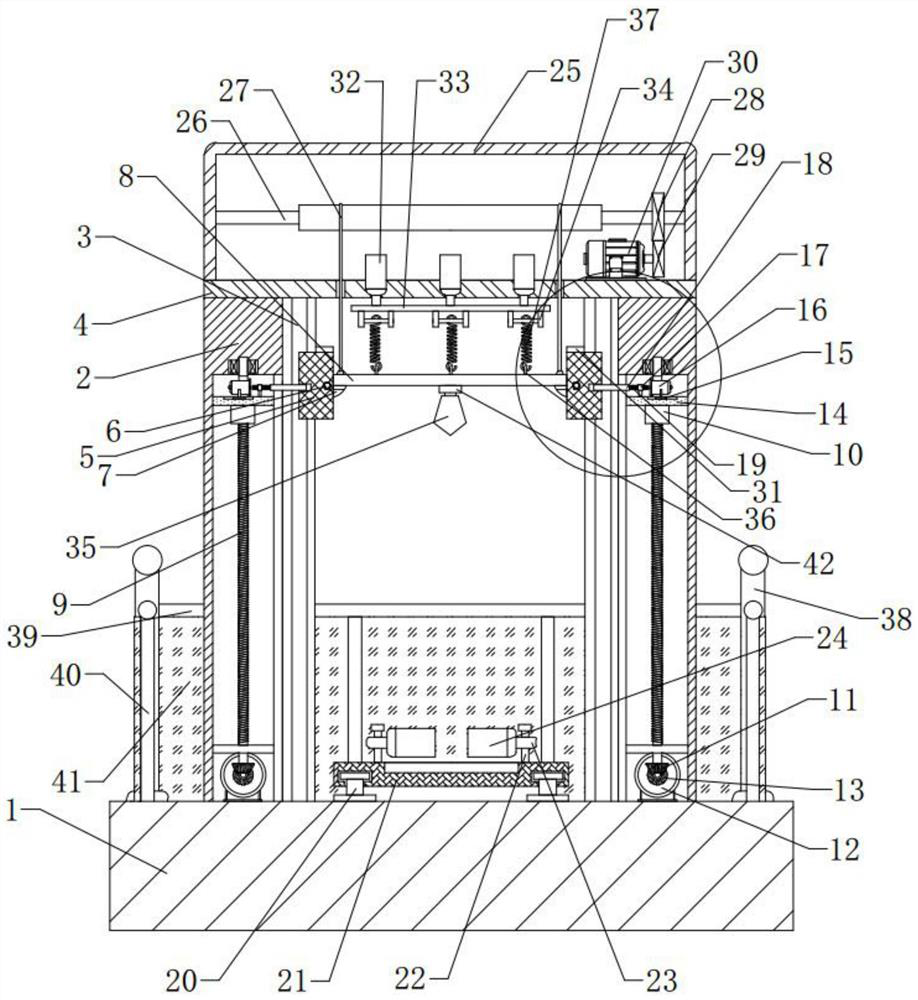

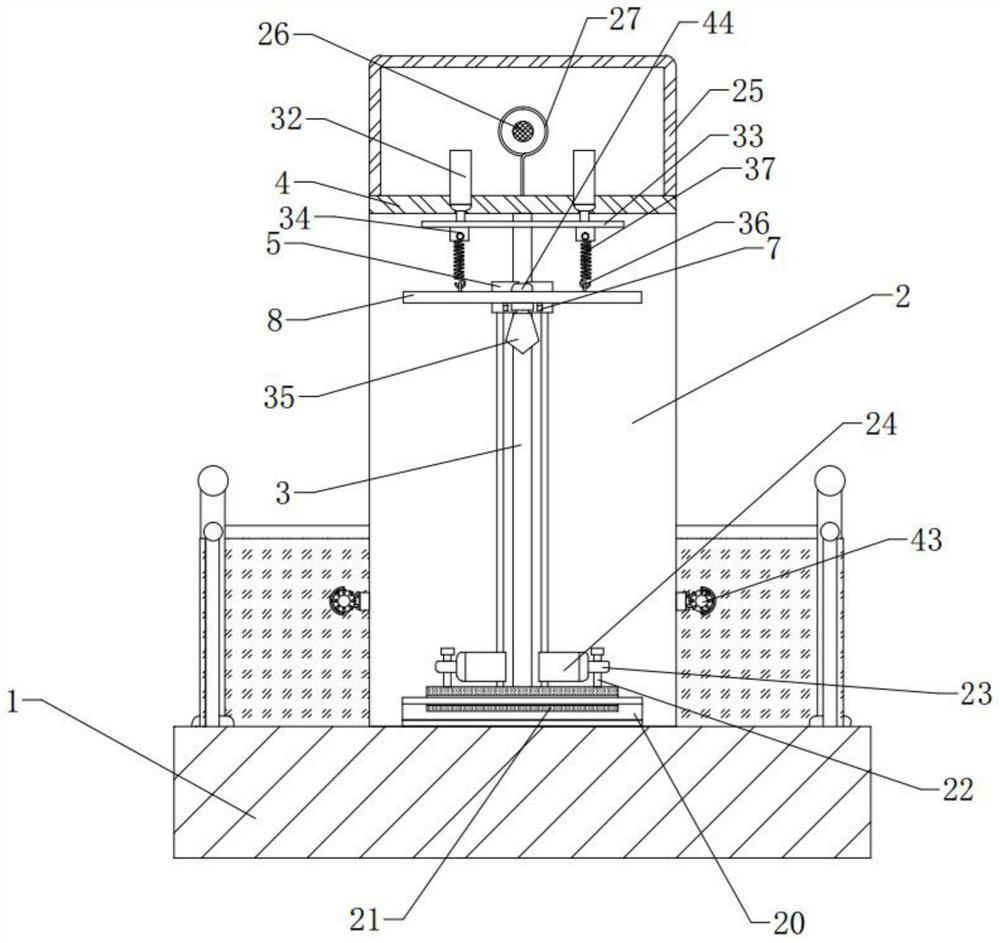

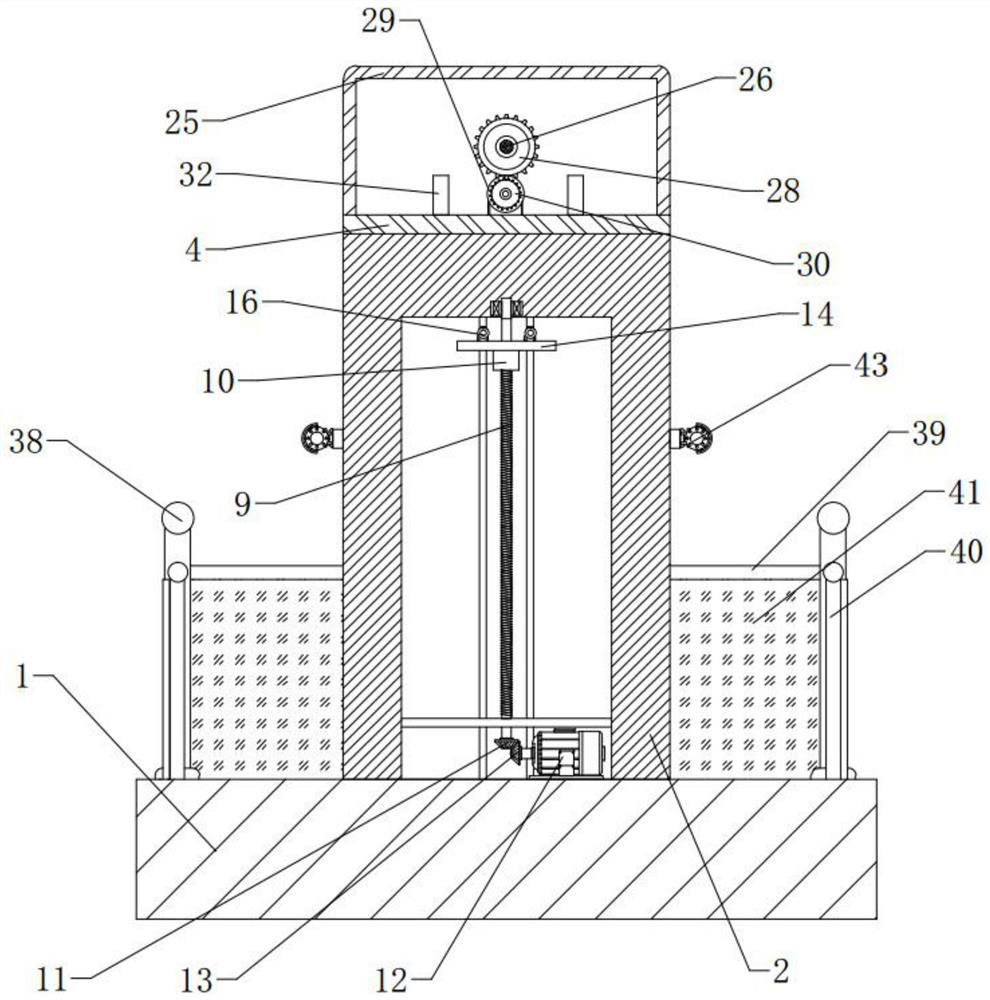

[0049] Embodiment: When in use, the test bench 1 is placed on the flat ground in the laboratory, and the whole device is placed on the test bench 1 to reduce the pressure on the ground. A pair of vertical boards 2 are installed on both sides of the upper wall of the test bench 1, The vertical slide rail 3 is installed on the opposite wall, and splicing blocks 5 are installed on both sides of the vertical slide rail 3. After the splicing blocks 5 are docked, they are connected and fixed with bolts 6, and can move up and down on the vertical slide rail 3. The horizontal plate 8 passes through The limit block 7 is fixed on two pairs of spliced splicing blocks 5, the threaded shaft 9 is installed in the vertical groove in the riser 2, and the driven bevel gear 11 is installed on the lower end, and the first servo motor 12 and its Driven by the active bevel gear 13, two pairs of splicing blocks 5 are provided with sockets on the rear wall, and a ball nut 10 is installed on the thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap