Automatic ejection device for injection molds

An automatic ejection and injection mold technology, applied in the field of injection molds, can solve problems such as complex results, additional air sources, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

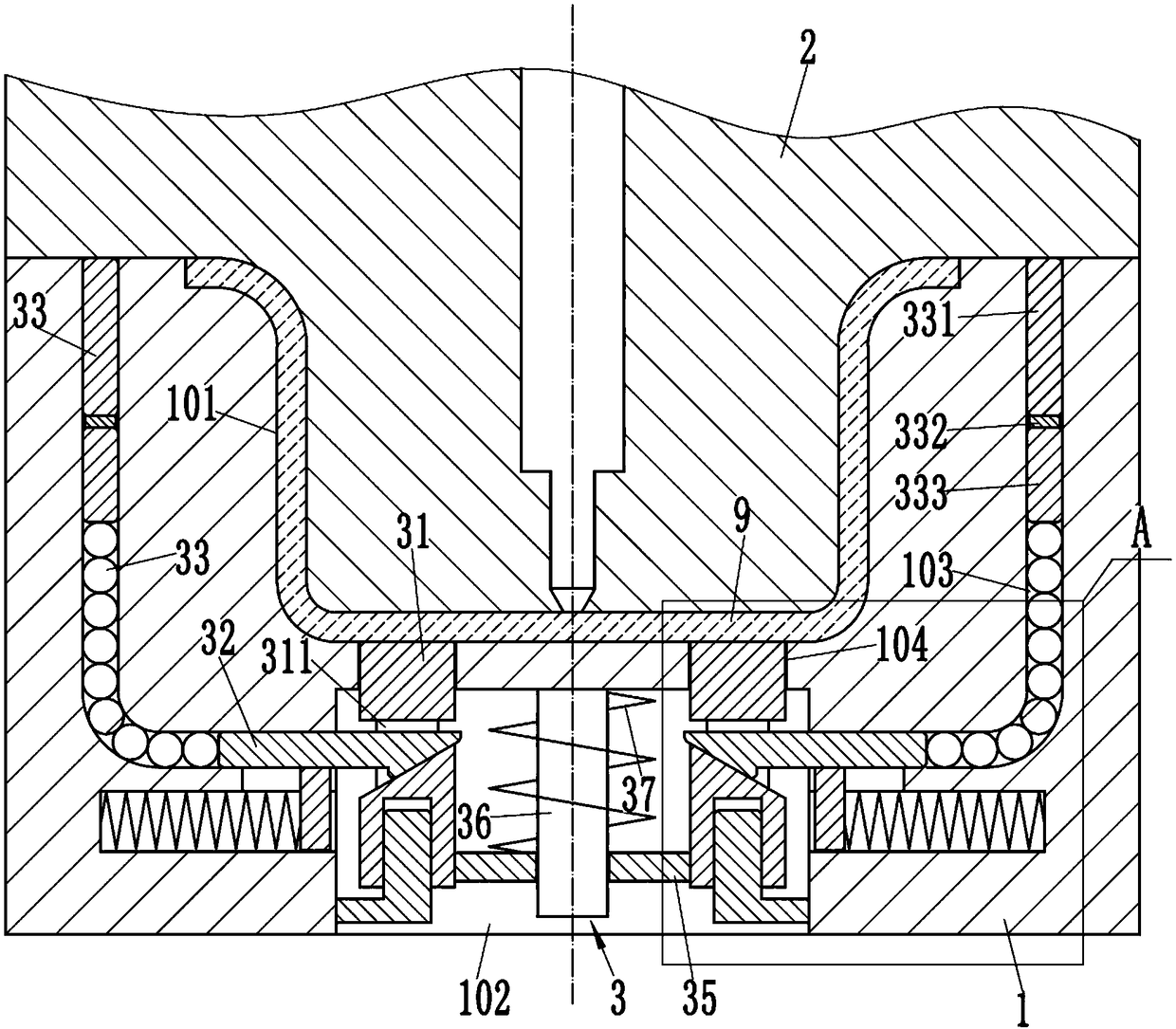

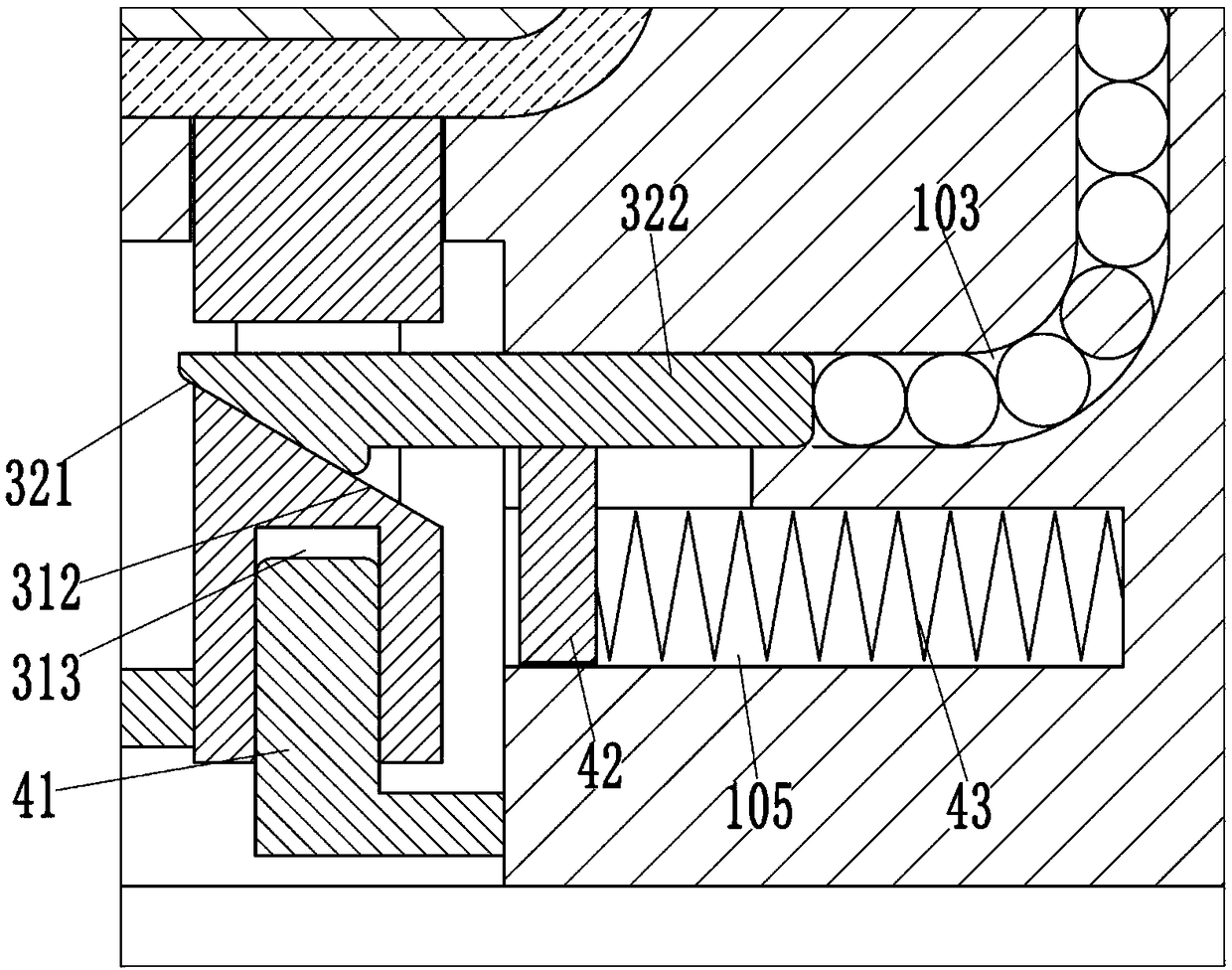

[0014] Example, see as Figure 1 to Figure 2 As shown, an automatic ejection device for an injection mold includes a concave mold 1 and a convex mold 2 that can move up and down. The concave mold 1 is formed with a concave mold cavity 101, and the convex part of the convex mold 2 is inserted into the concave mold cavity 101 , The plastic product 9 is molded in the cavity formed by the concave mold cavity 101 and the convex mold 2. The concave mold 1 is provided with an automatic ejection device 3, and the concave mold 1 is molded with a driving cavity 102 with a lower side opening and a For the L-shaped channel 103 arranged symmetrically, the lower end of the L-shaped channel 103 communicates with the driving cavity 102. Two parallel thimble holes 104 are provided between the cavity 101 and the driving cavity 102. The outlet device 3 includes two thimble pins 31 respectively inserted and sleeved in the two thimble holes 104. The center of the thimble 31 is formed with a left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com