Aircraft wing trimming device

An aircraft and airfoil technology, applied in the field of aircraft trim design, can solve the problems of increasing the pilot's control burden and not having the follow-up compensation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

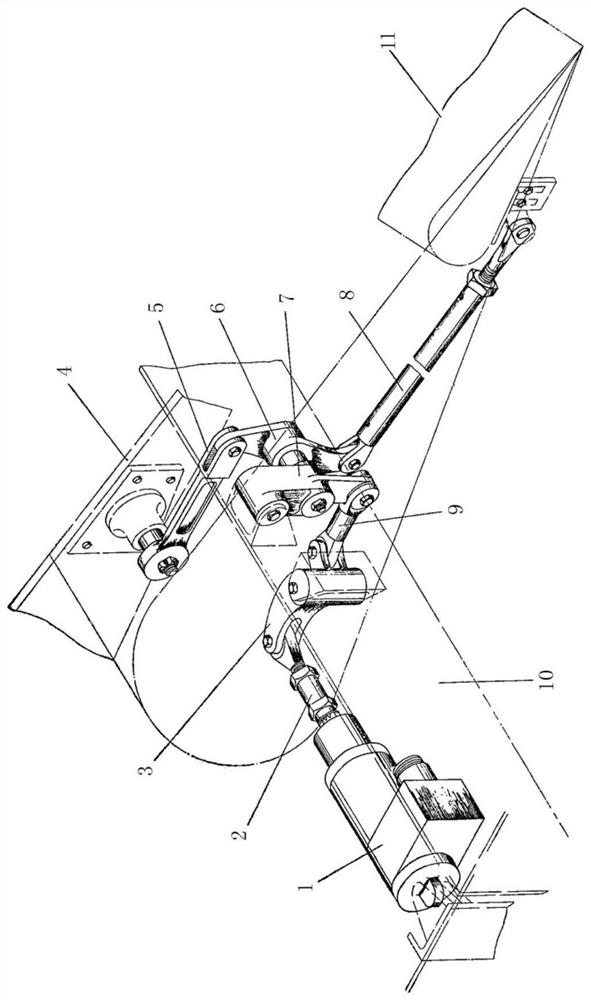

[0013] See attached figure 1 In this embodiment, an aircraft wing surface trimming device is proposed, including an electric mechanism 1, a first connecting rod 2, a first double-arm rocker 3, an aileron suspension arm 4, a second connecting rod 5, a second double Rocker arm 6, rocker arm 7, pull rod 8, third connecting rod 9, aileron beam 10 and aileron trim piece 11;

[0014] The electric mechanism 1 is installed on the aileron girder 10 , the actuator of the electric mechanism 1 is fixedly connected with one end of the first connecting rod 2 , and the other end of the first connecting rod 2 is connected with the first double-arm rocker arm 3 installed on the aileron girder 10 One support arm is hinged, the upper lug of the rocker arm 7 is hinged on the bracket of the aileron beam 10, the middle hole of the rocker arm 7 is hinged with the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com