Trimmer

A technology of edge trimming machine and casing, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of no decorative plate trimming machine, single function, complex structure, etc., and achieve the smoothness of the workpiece , low labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

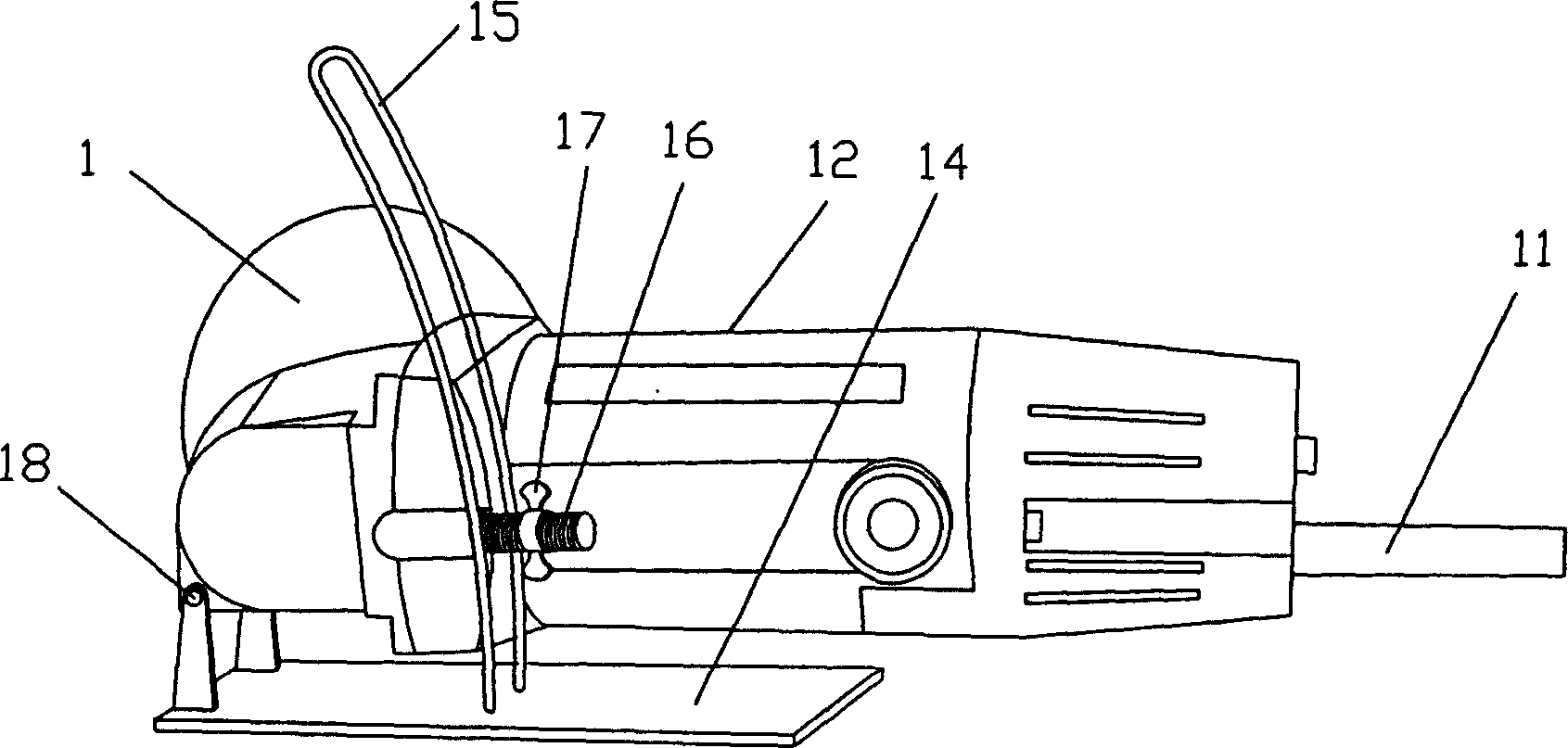

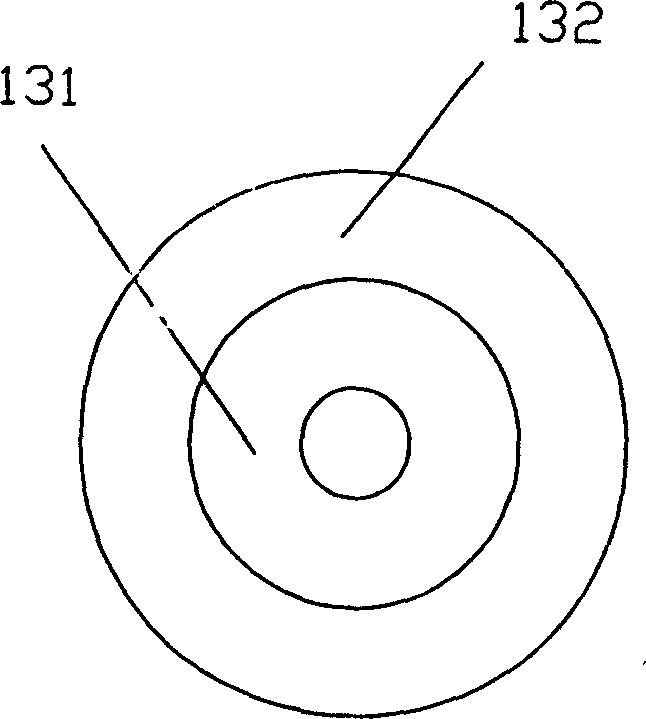

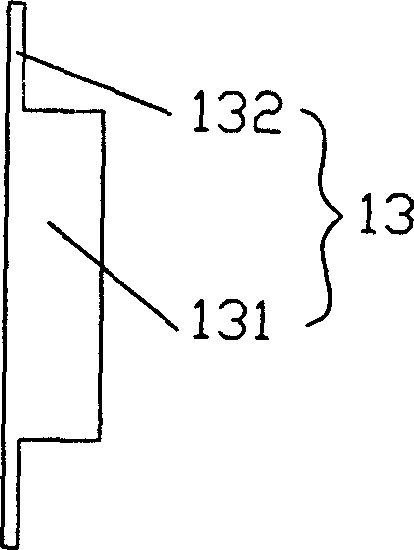

[0018] see Figure 1-4 , the present invention is provided with grinding wheel cover 1, output shaft 2, bearing 3, large helical gear 4, small helical gear 5, fan blade 6, stator 7, armature 8, electric brush 9, switch 10, cable 11, casing 12 , Conical grinding wheel 13, base 14, adjusting rod 15, fixed pin 16 and fixed nut 17. The frustum-shaped grinding wheel 13 is fixed on the output shaft 2, and the transmission mechanism composed of the large helical gear 4 and the small helical gear 5 is arranged at the front of the casing 12, the small helical gear 5 meshes with the large helical gear 4, and the wind blades 6, The stator 7 and the armature 8 are arranged in the middle of the inner cavity of the casing 12, the brushes 9 and the switch 10 are arranged at the rear of the inner cavity of the casing 12, the cables 11 are drawn out of the rear of the casing 12, and the grinding wheel cover 1 is covered in a round On the top of the table-shaped grinding wheel 13, the armature...

Embodiment 2

[0020] Similar to Example 1, the difference is that the grinding wheel and the grinding wheel cover of Example 1 are arranged on one side of the front of the casing, and the transmission mechanism adopts the meshing mode of the large helical gear and the small helical gear, while the grinding wheel and the grinding wheel cover of Example 2 It is located at the front of the casing, and the transmission mechanism is replaced by a reducer. The grinding wheel can be a split grinding wheel with a small diameter of 6cm and a large grinding wheel with a diameter of 10cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com