Energy efficiency detecting method and device of boiler

A detection method and boiler technology, applied in the direction of measuring devices, machine/structural components testing, instruments, etc., can solve problems such as restricting the development of electric heating, not fully applicable to electric boiler evaluation, energy efficiency evaluation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0087] The invention provides a method for detecting energy efficiency of a boiler, such as figure 1 As shown, the method includes the steps of:

[0088] Control the boiler to enter the heating stage, stable stage and cooling stage in turn and measure the boiler parameters in the heating stage, stable stage and cooling stage respectively;

[0089] Carry out energy efficiency detection on the boiler according to the boiler parameters in the heating stage, stable stage and cooling stage;

[0090] Wherein, the boiler parameters include boiler water supply temperature, circulating water flow, return water temperature and real-time power.

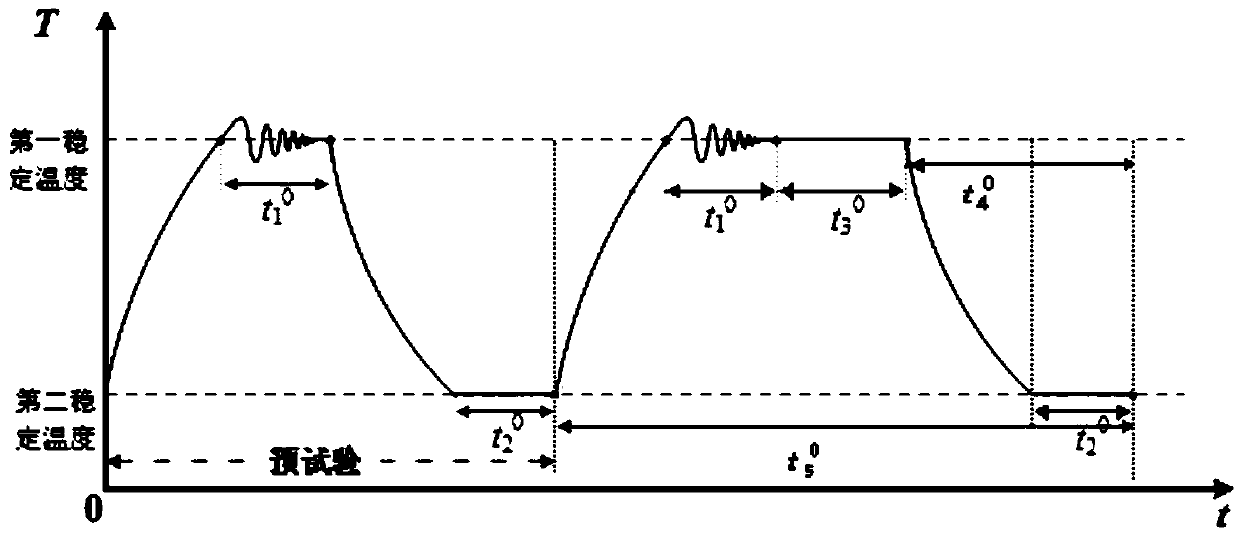

[0091] Specifically, before the control boiler enters the heating stage, the stable stage and the cooling stage successively and measures the boiler parameters of the heating stage, the stable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com