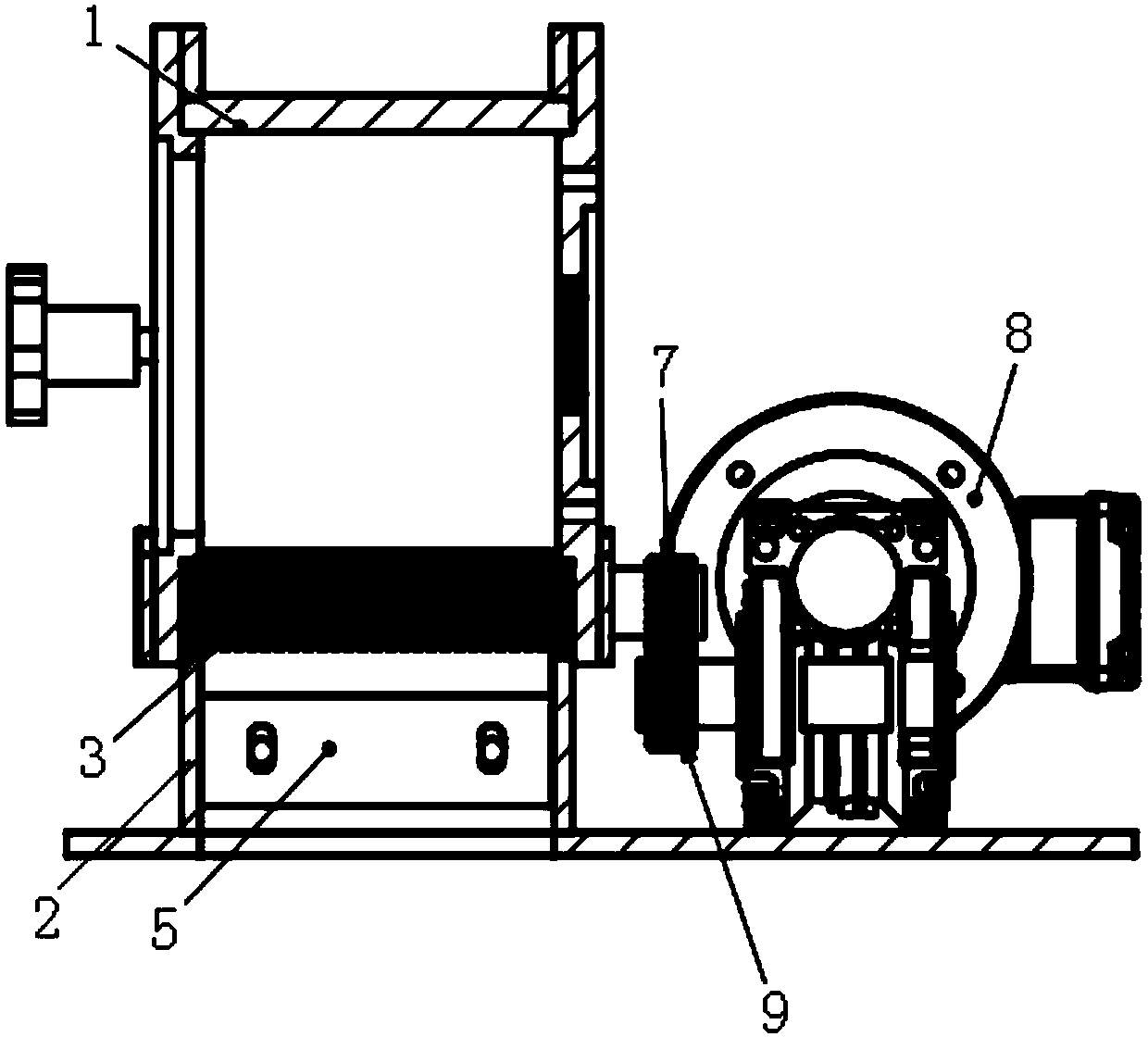

Double-screen-roller discharging mechanism

A sieve roller and blanking technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing the cost of manual cleaning, unable to unload, and affecting the effect of unloading broken materials, etc., to achieve reasonable structure and unloading Good effect, improve the effect of cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

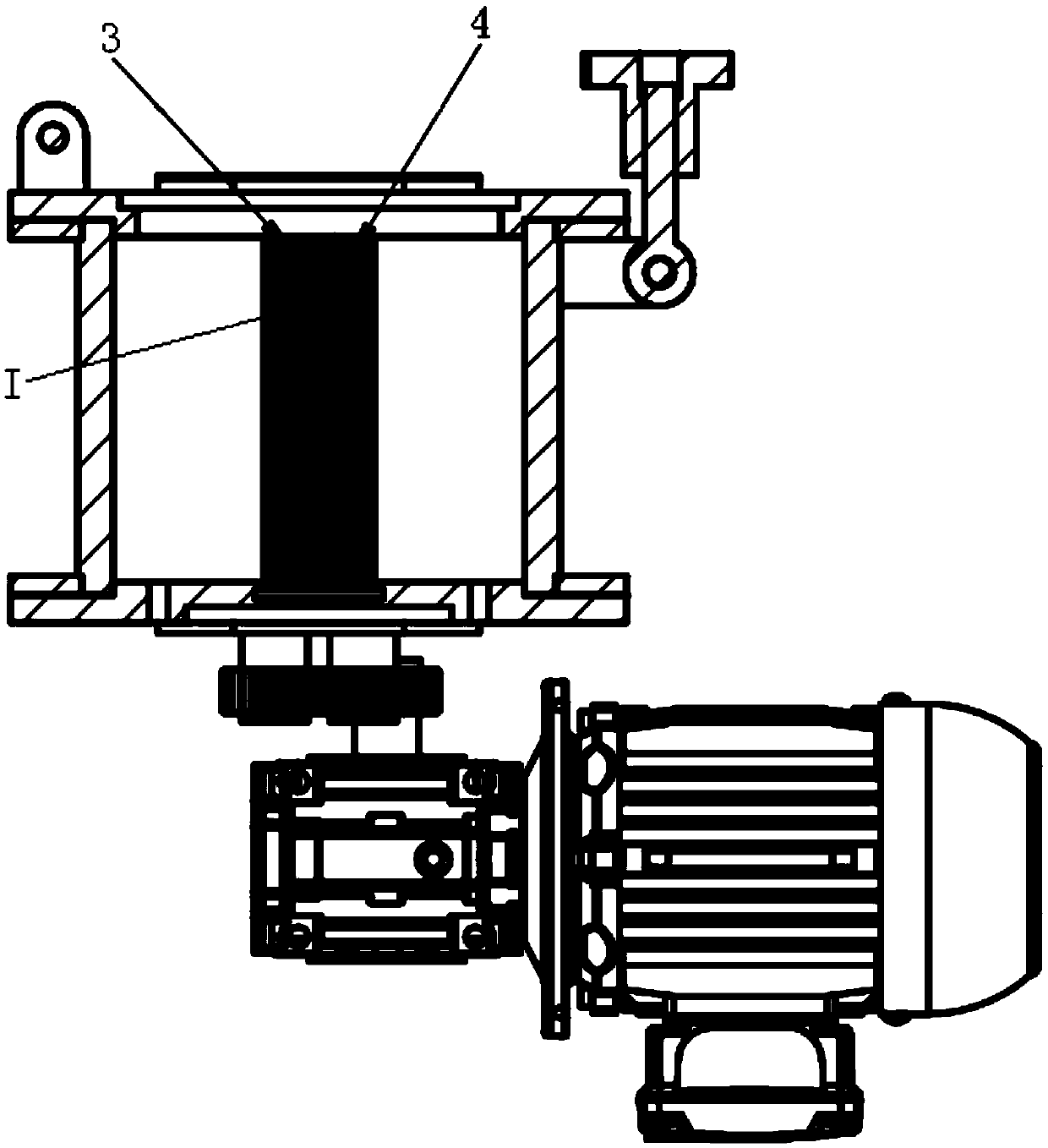

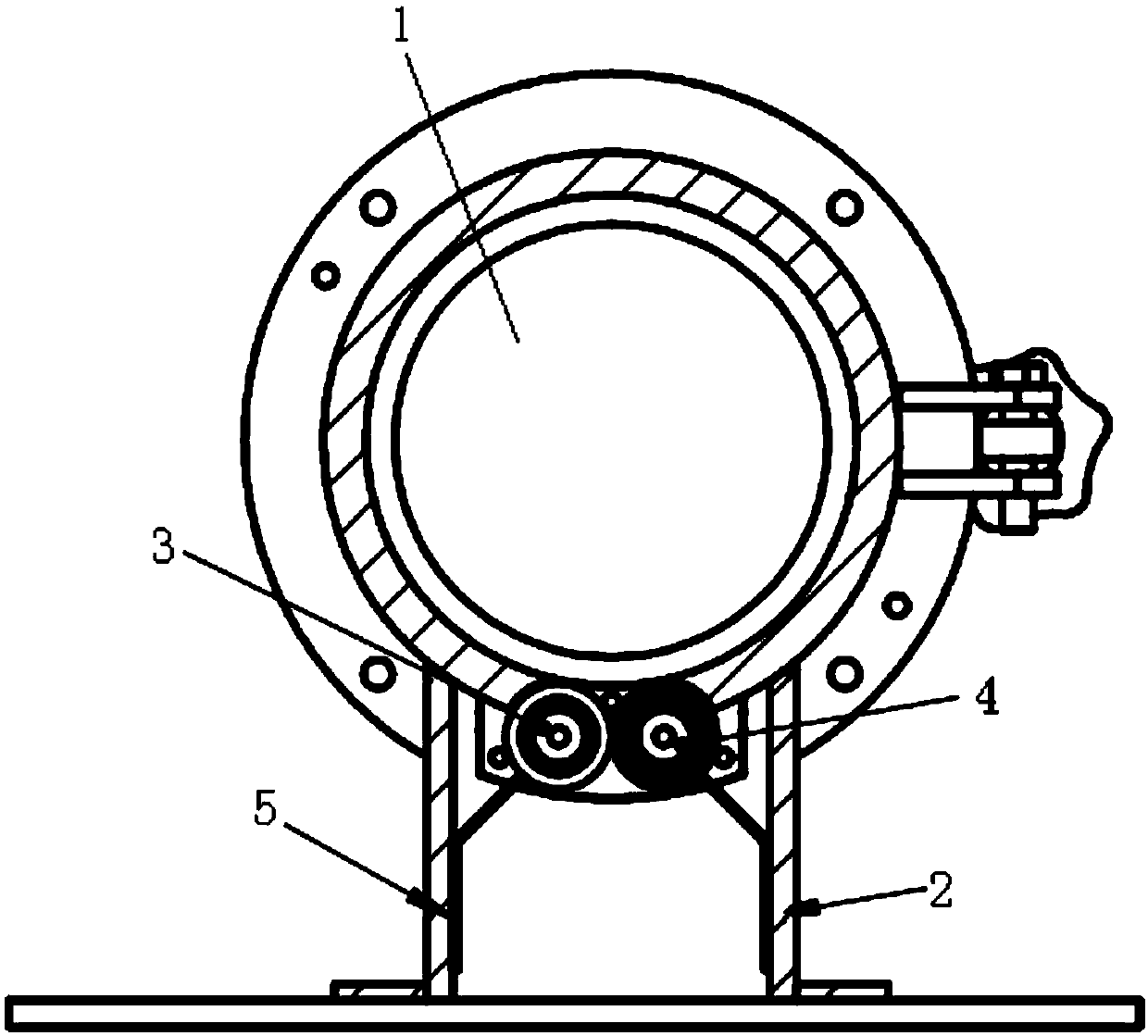

[0028] When in use, turn on the sieve roller drive motor. Driven by the driving gear, the two driven gears rotate inward at the same time. The material falls into the screening gap between the first sieve roller and the second sieve roller. The second sieve roll rotates inward, because the teeth of the first sieve roll and the second sieve roll are placed corresponding to the sieving gap of the first sieve roll and the second sieve roll, the roller teeth press the material into the sieving gap, inward After being rotated, it falls into the lower silo, which can also achieve the effect of further crushing.

[0029] If there is material stuck in the sieving gap with the first sieve roller and the second sieve roller rotating, when it passes the bottom end, it will contact with the scraping teeth at the end of the scraping part arranged obliquely, and the stuck material It will be blocked by the scraper teeth, thrown at the bottom of the inclined scraper under the action of inertia,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com