High-stability special ceramic preparation device

A special ceramic, high-stability technology, applied in clay preparation devices, clay mixing devices, chemical instruments and methods, etc., can solve the problems of reducing work efficiency, prolonging preparation time, etc., to achieve the effect of increasing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

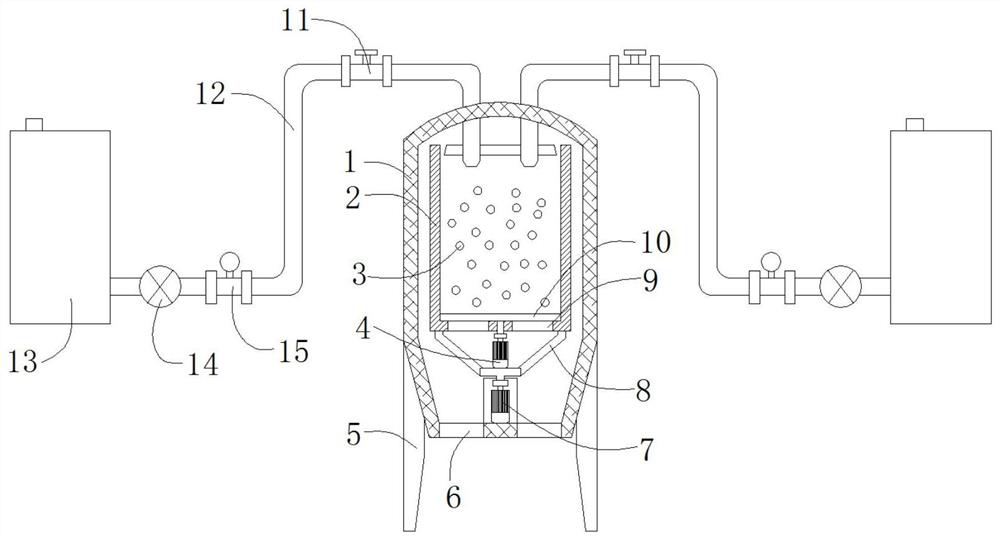

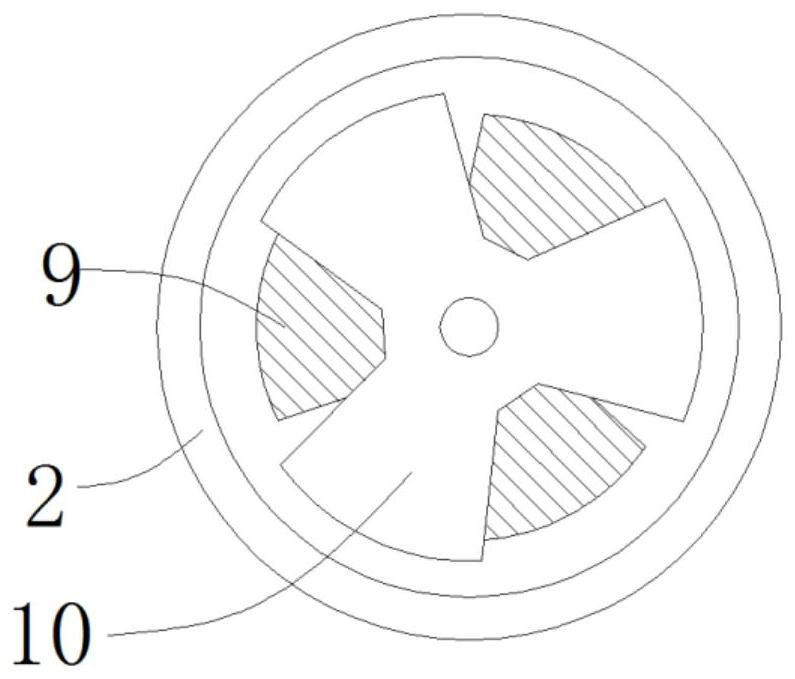

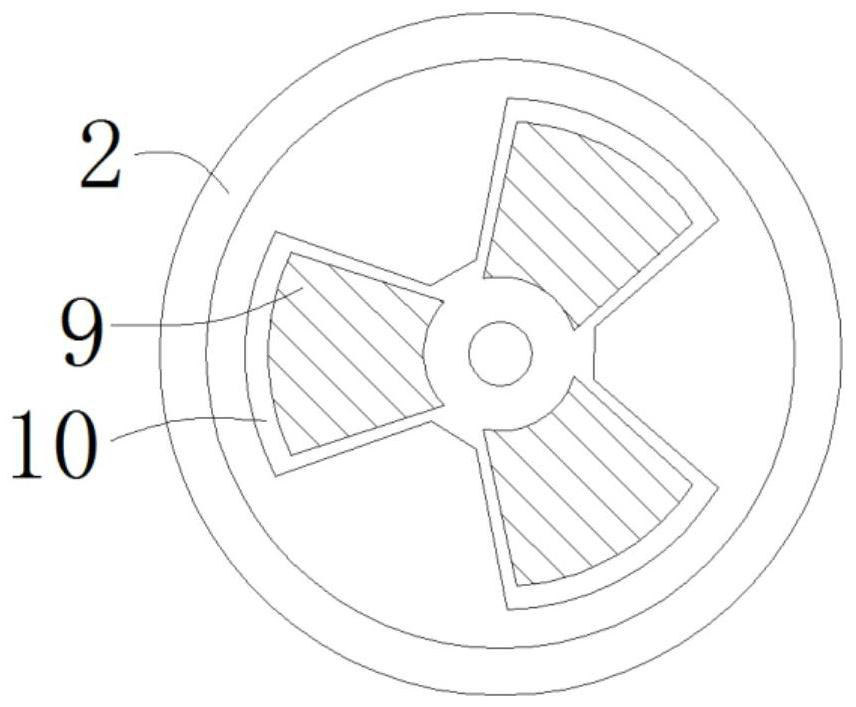

[0025] Example: refer to Figure 1-4 , a high-stability special ceramic preparation device, comprising a preparation tank 1, a ball mill mechanism, a tank leg 5, a material tank 13, a pump body 14 and a feeding pipe 12, the bottom of the preparation tank 1 is welded with four tank legs 5, prepared The connection between the tank 1 and the material tank 13 is transmitted through the material tank 13, and the pump body 14 is arranged between the material tubes 12;

[0026] One end of the feeding pipe 12 is connected to the material tank 13, and the other end of the feeding pipe 12 is inserted into the through hole provided above the preparation tank 1, and the outer ring of the feeding pipe 12 placed in the preparation tank 1 is also fixedly glued. There is a clamping plate, and the clamping plate is placed at the upper opening of the ball mill box 2.

[0027] Specifically, in the external space of the preparation tank 1, through the connection of the feeding pipe 12, two feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com