Transformer fast riveting tool

A technology for transformers and tooling, which is applied in the field of fast riveting tooling for transformers, and can solve problems such as large size differences and riveting differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

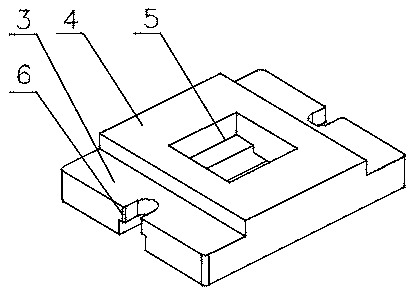

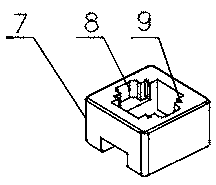

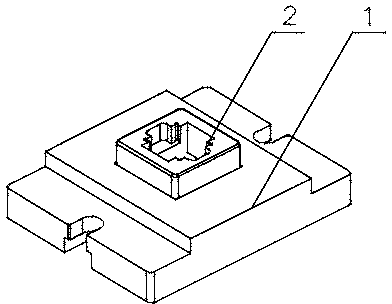

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation to the present invention: a quick riveting tool for a transformer, characterized in that it includes a base 1 and a mold core 2, and the mold core 2 is arranged on the base 1; The base 1 includes a limit structure 3, a base body 4 and a mold core installation structure 5, the limit structure 3 includes a base limit slot 6, and the base limit slot 6 is symmetrically arranged on the base 1 The front and rear sides; the core installation structure 5 is set in the middle of the base 1 and fixed with the core 2; the core installation structure 5 is a quadrilateral structure, and the bottom is a stepped structure; the core 2 includes The mounting base 7 and the micro switch limit structure 8, the bottom of the mounting base 7 cooperates with the stepped structure of the mold core installation structure 5, and the outside of the mold core 2 is a quadrilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com