Ultrasonic detection 3D printer capable of avoiding powder interference

A 3D printer and ultrasonic technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, improving energy efficiency, and improving process efficiency, which can solve problems affecting the detection accuracy of ultrasonic detection devices and powder scattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

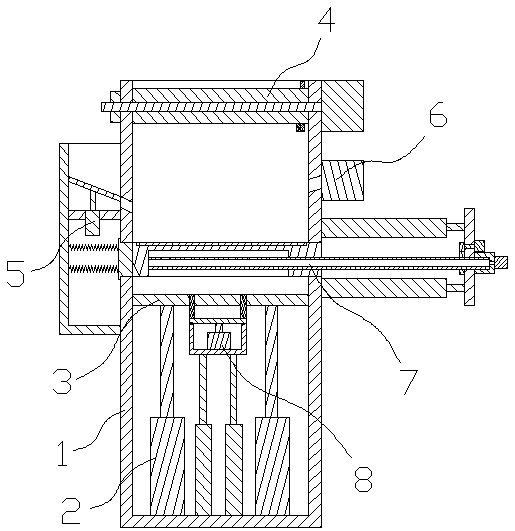

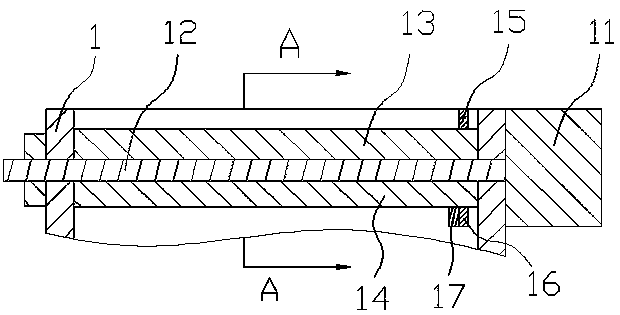

[0026] Such as figure 1 with 4 As shown in -6, the specific structure of the present invention is: an ultrasonic detection 3D printer capable of avoiding powder interference, including a molding box 1, a molding platform 3 provided by a molding lifting cylinder 2 in the molding box 1, and a feeding material set on the side of the molding box Device 5, gas regulating device 6 and scraping device 7, the upper part of the forming box 1 is provided with a scanning detection mechanism 4, the scraping device 7 includes a scraping cylinder 21 arranged on the side of the molding box 1, the The scraping cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com