Roller bearing transfer module and roller bearing transfer machine

A technology of fulai wheel and transfer machine, which is applied to the field of fulai wheel transfer module and fulai wheel transfer machine, can solve the problems such as the inability to transport the box body smoothly and the insufficient power of the driven wheel group, so as to reduce the probability of insufficient power, Guaranteed smooth delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

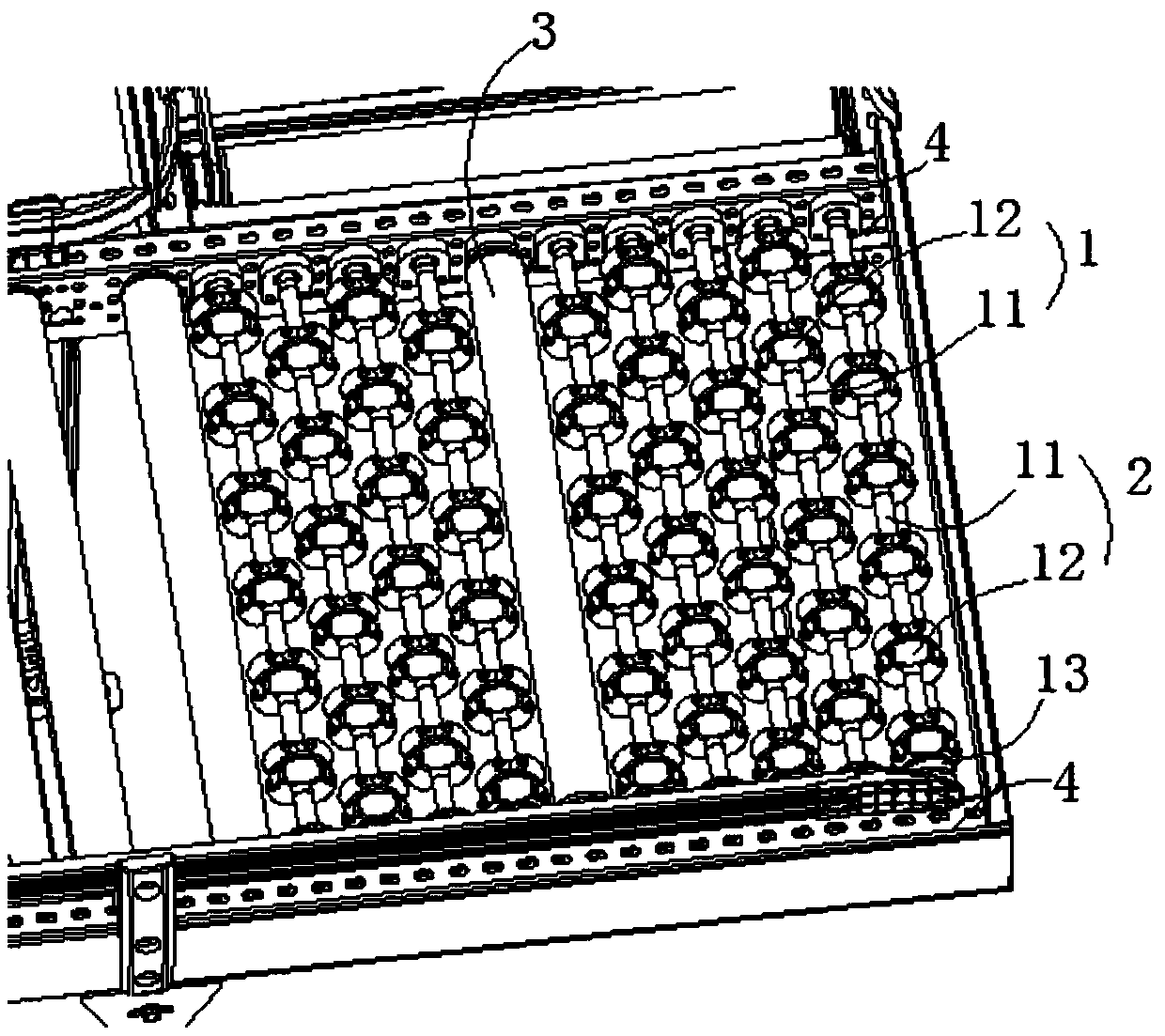

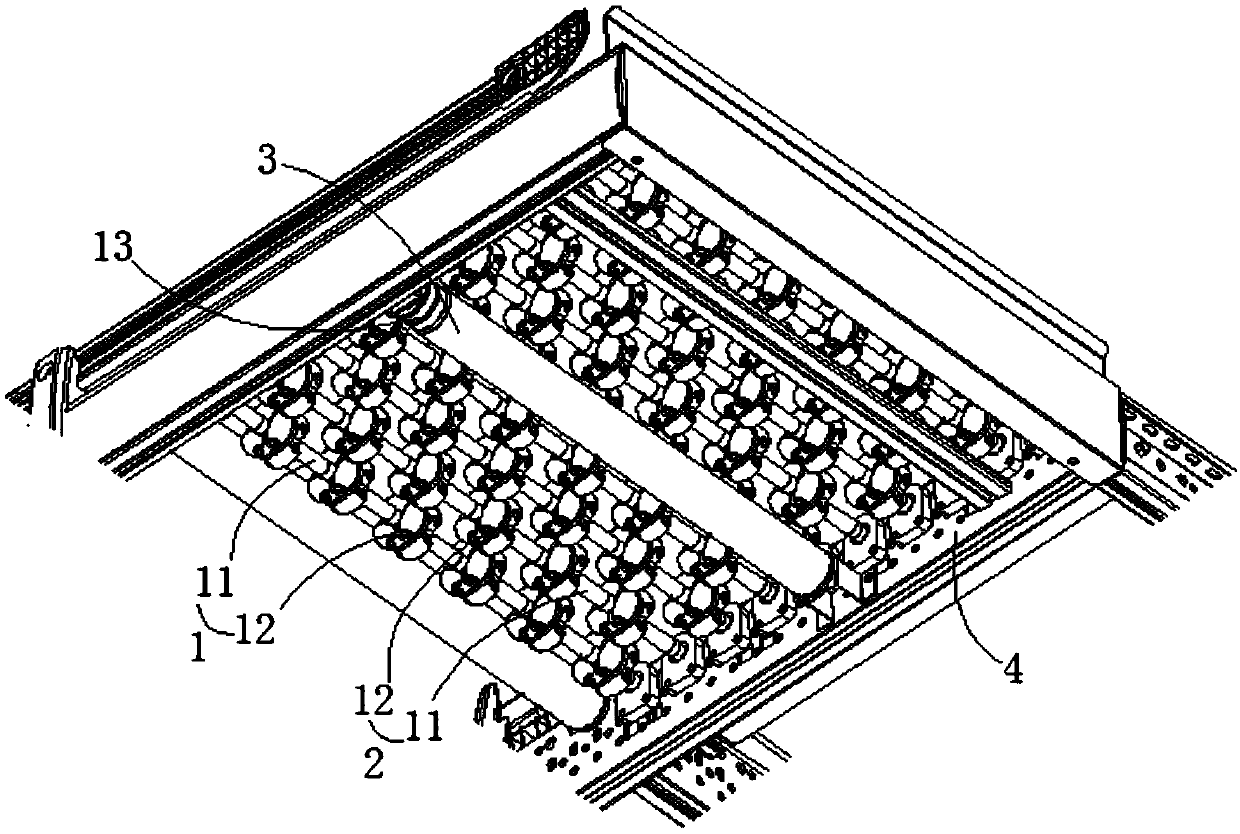

[0028] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a Fulai wheel transfer module, including a first driven wheel set 1, a second driven wheel set 2 and an electric roller 3 arranged parallel to each other. The electric roller 3 has one and is connected to the first The driven wheel set 1 and the second driven wheel set 2 are transmission connected; the first driven wheel set 1 and the second driven wheel set 2 all include a sleeve 11 and a plurality of freewheels 12 fixed on the sleeve 11 at equal intervals. The driven wheel set 1 is adjacent to the second driven wheel set 2 or the electric roller 3, and the second driven wheel set 2 is adjacent to the first driven wheel set 1 or the electric roller 3. The Freewheels 12 and the Freewheels 12 on the adjacent second driven wheel set 2 are arranged in an interlaced manner in the axial direction of the casing 11 .

[0029] In the free wheel transfer module provided by the embodiment ...

Embodiment 2

[0050] Such as figure 1 As shown, the embodiment of the present invention provides a freewheel transfer machine, including at least one freewheel transfer module as described above.

[0051] The technical advantages of the freewheel transfer machine provided by the present invention are the same as those of the abovementioned freewheel transfer module, and will not be repeated here.

[0052] It is worth noting that when multiple Freewheel transfer modules are used, this embodiment preferably sets the number of the first driven wheel group 1 and the second driven wheel group 2 in the multiple Freewheel transfer modules and the ratio of the electric roller 3 The arrangements are all the same; alternatively, the number of the first driven wheel group 1 and the second driven wheel group 2 in the Fulai wheel transfer module can also be set to be different but the arrangement method is the same as that of the electric roller 3. This setting is more flexible and more efficient. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com