Cable pulley assembly

A pulley and component technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of offset, affecting the quality of the cable, changing the direction, etc., to achieve the effect of ensuring the transmission effect and the smoothness of the conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

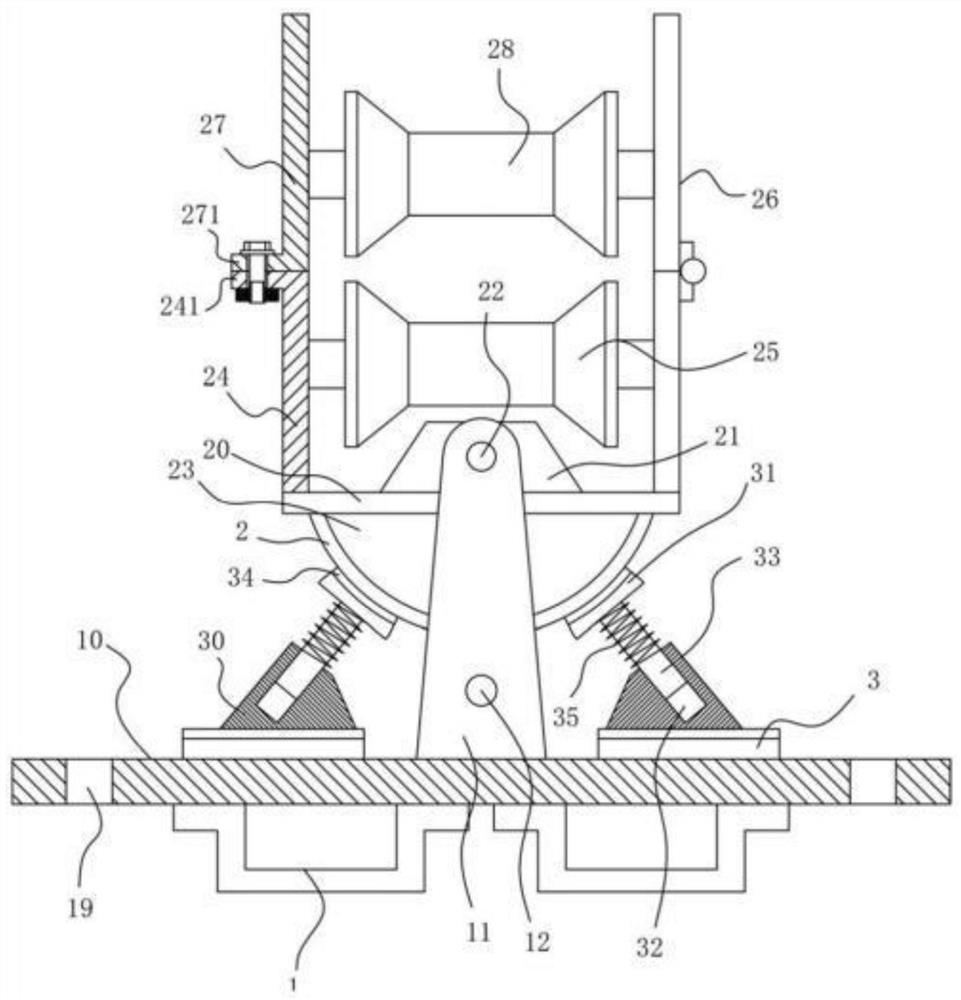

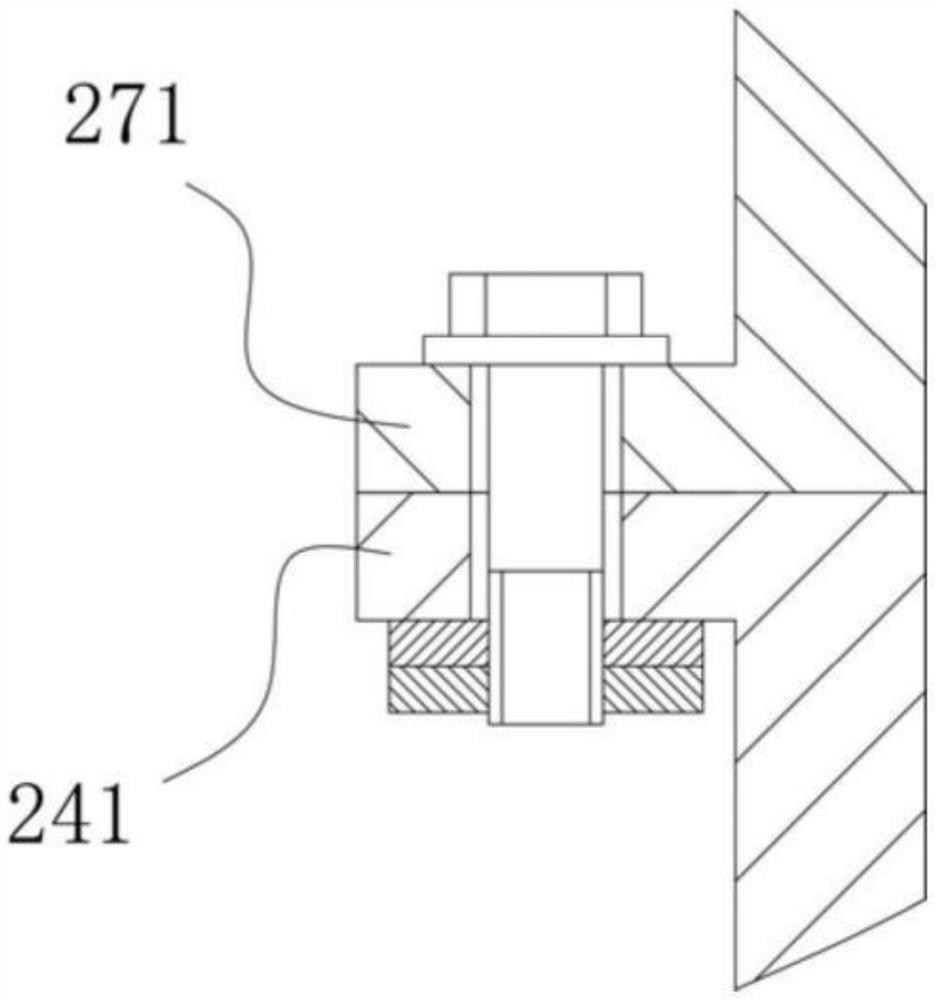

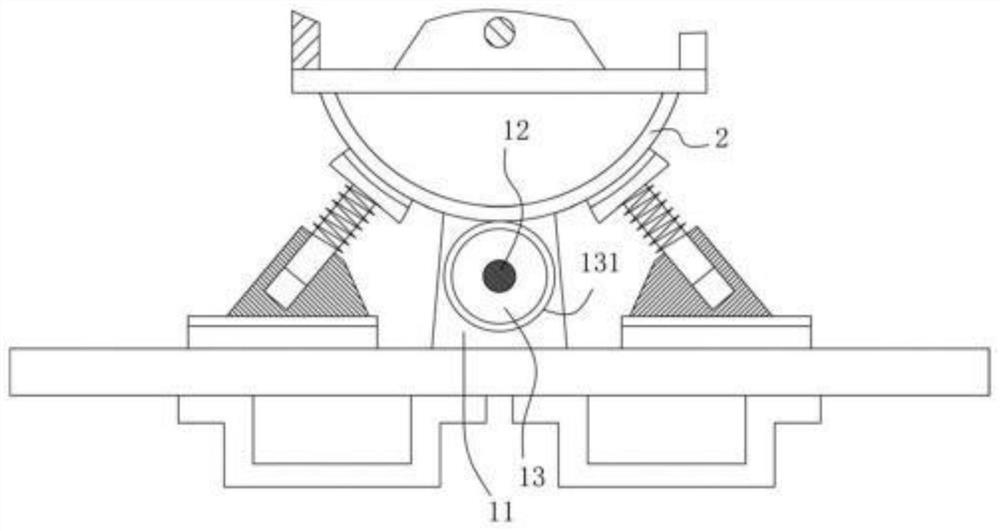

[0021] Example: see Figure 1 to Figure 3 As shown, a cable trolley assembly includes a base 10, the front and rear parts of the top surface middle of the top plate of the base 10 are fixed with vertical support plates 11, and the lower parts of the two vertical support plates 11 are fixed with lower The connecting shaft 12, the middle part of the lower connecting shaft 12 is hinged with the lower roller 13 through the bearing, the upper fixing plate 20 is between the two vertical support plates 11, and the upper fixing block 21 is fixed on the top surface middle part of the upper fixing plate 20, and the upper fixing The middle part of block 21 is hinged with upper connecting shaft 22 by bearing, and upper connecting shaft 22 is fixed on two vertical supporting plates 11, and the bottom surface middle part of upper fixing plate 21 is fixed with arc-shaped block 23, and the side wall of arc-shaped block 23 is tight. Paste the side wall of the roller 13;

[0022] The left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com