Pre-insertion indexing mechanism for motor stator insulated slot wedge

A technology of motor stator and indexing mechanism, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of bending insulating slot wedges, reducing the qualified rate of motor stators, etc., to improve the qualified rate and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

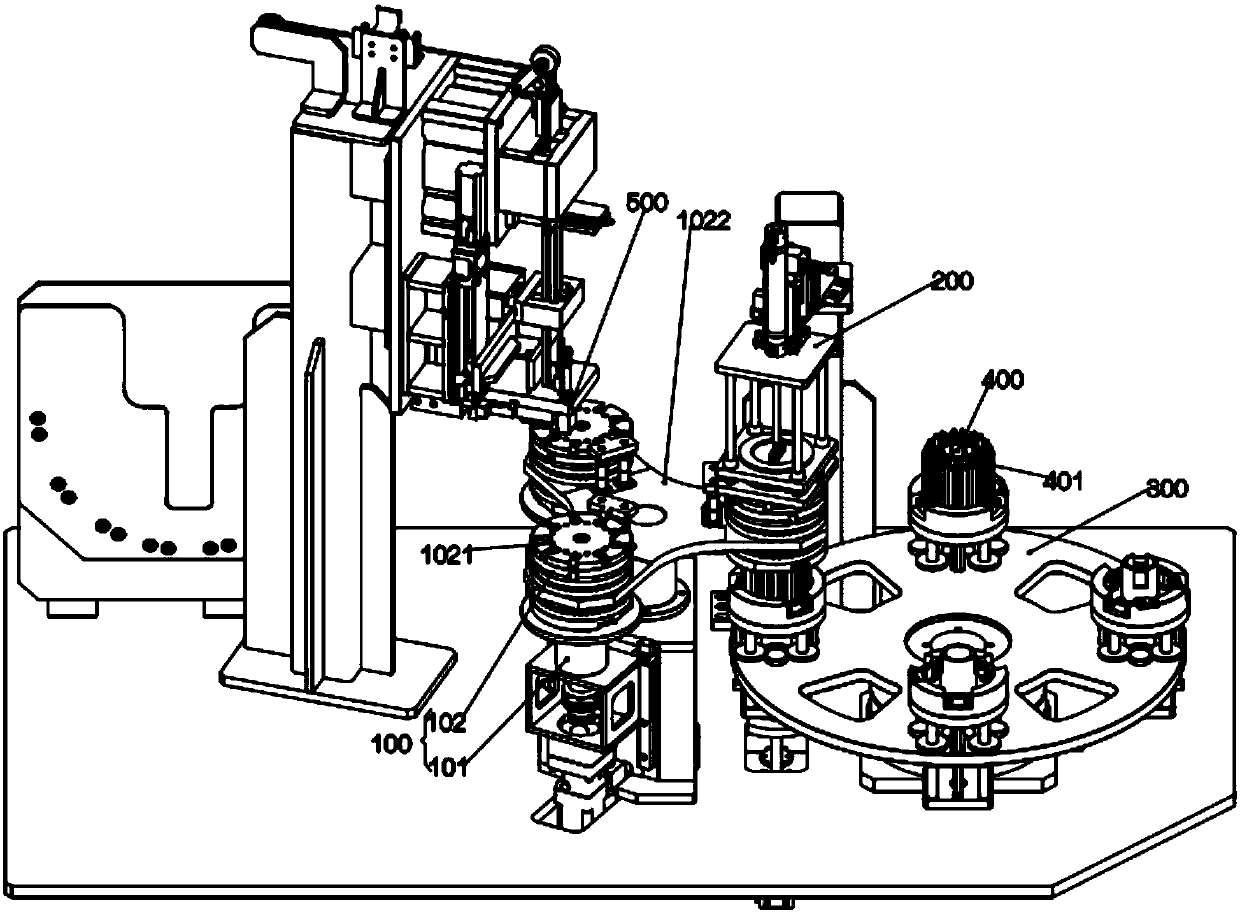

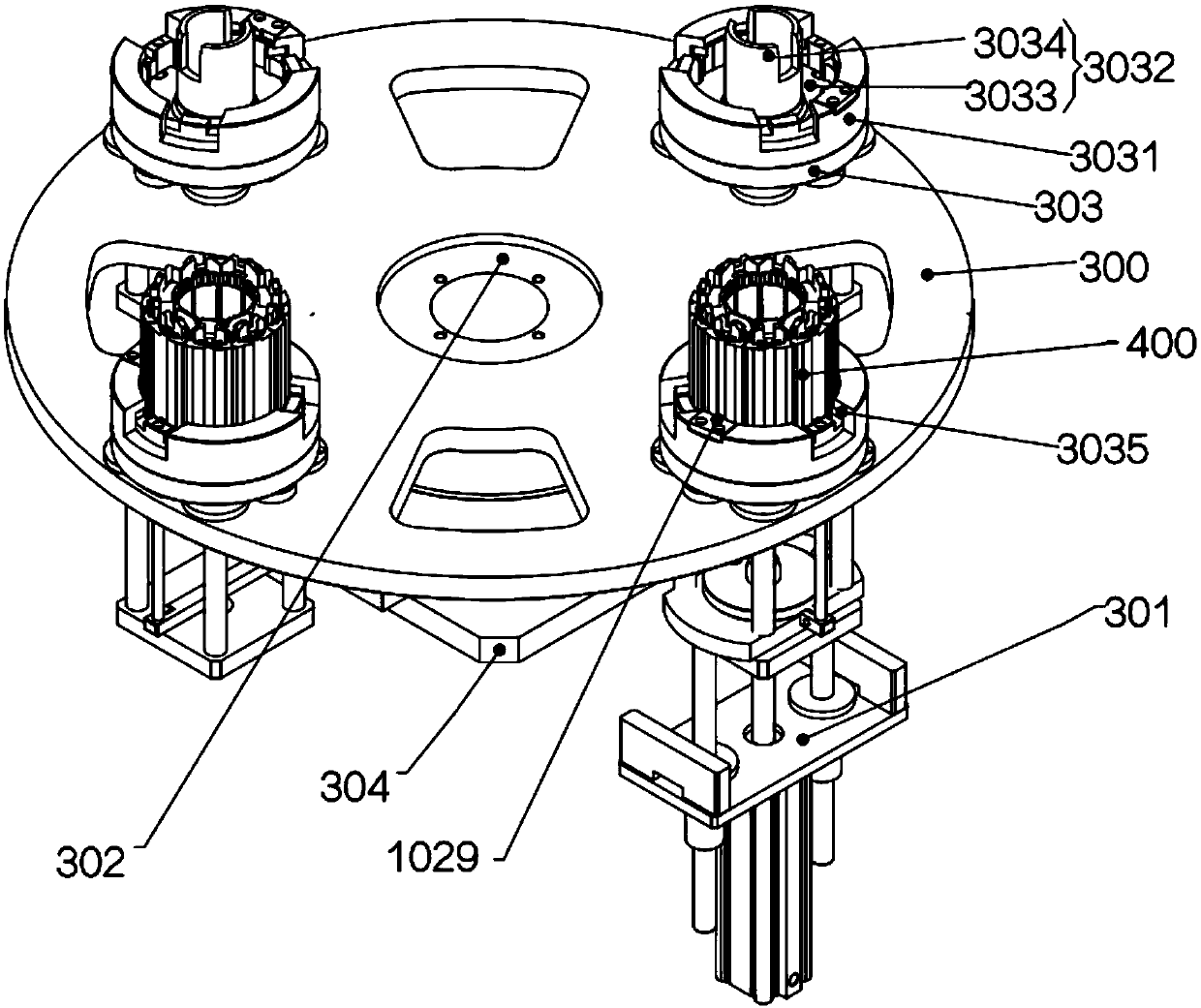

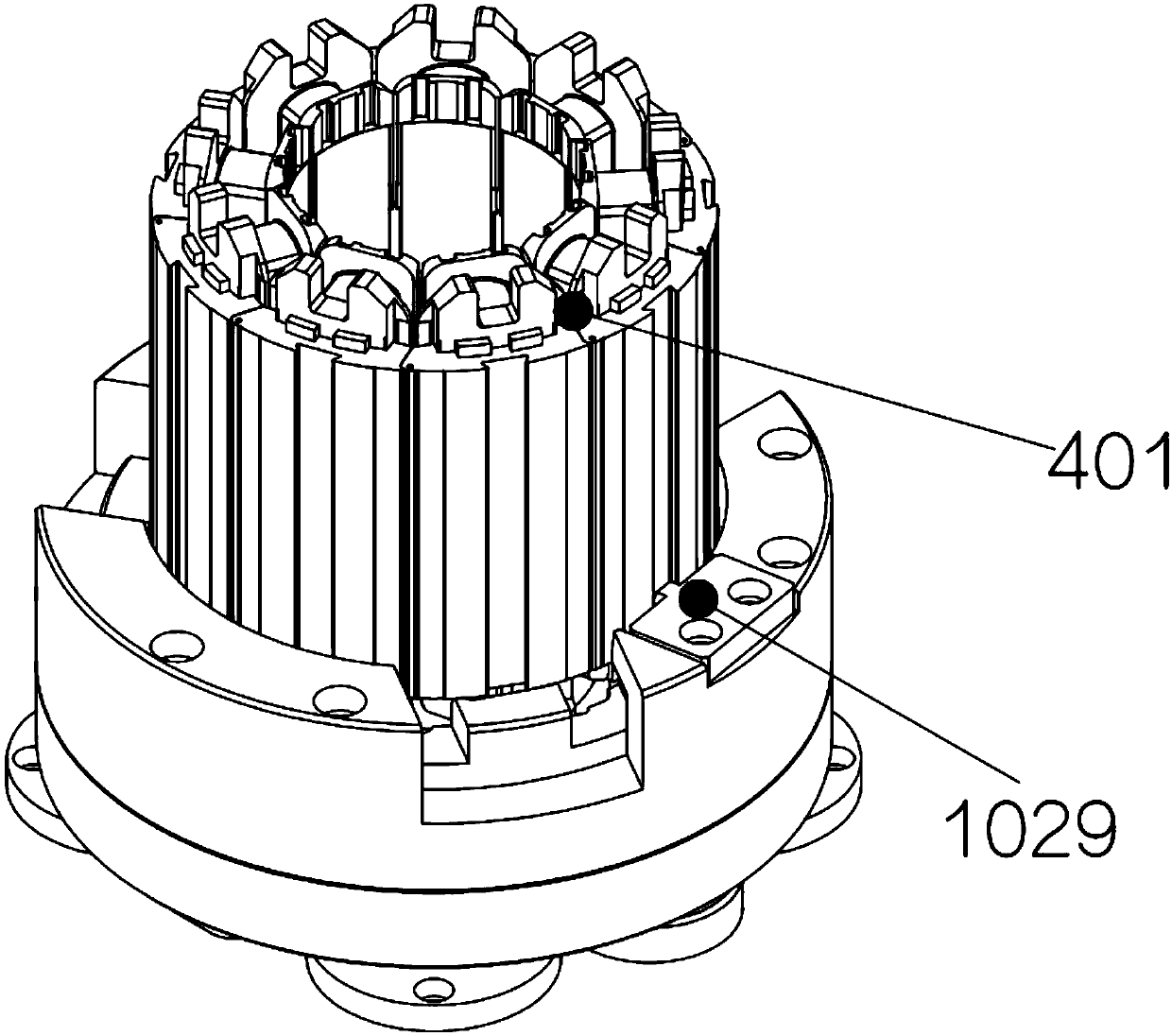

[0052] Such as figure 1 , Figure 4 to Figure 8 As shown, this embodiment provides a pre-insertion indexing mechanism 100 for motor stator insulation slot wedges, including a temporary storage device 102, and a temporary storage hole is provided on the temporary storage device 102 corresponding to the slot wedge installation hole 401 of the motor stator 400 1021 , the temporary storage hole 1021 is used for storing the slot wedge 600 .

[0053] The storage of the slot wedge 600 is facilitated by setting the temporary storage hole 1021. After the slot wedge 600 is stored in the temporary storage hole 1021, the pre-insertion indexing mechanism 100 is aligned with the slot wedge installation hole 401 of the motor stator 400, and force is applied to the pre-insertion When the slot wedge 600 in the indexing mechanism 100, the force direction of the insulating slot wedge 600 is facing the slot wedge installation hole 401, so as to avoid the bending of the insulating slot wedge 600 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com