Tea leaf processing equipment capable of improving processing efficiency of spherical tea leaves

A technology of processing efficiency and processing equipment, applied in the direction of pre-extraction tea processing, measuring devices, instruments, etc., can solve the problems of lack of physical quantity and poor tea processing effect, and achieve the effect of improving quality, eliminating quality instability and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

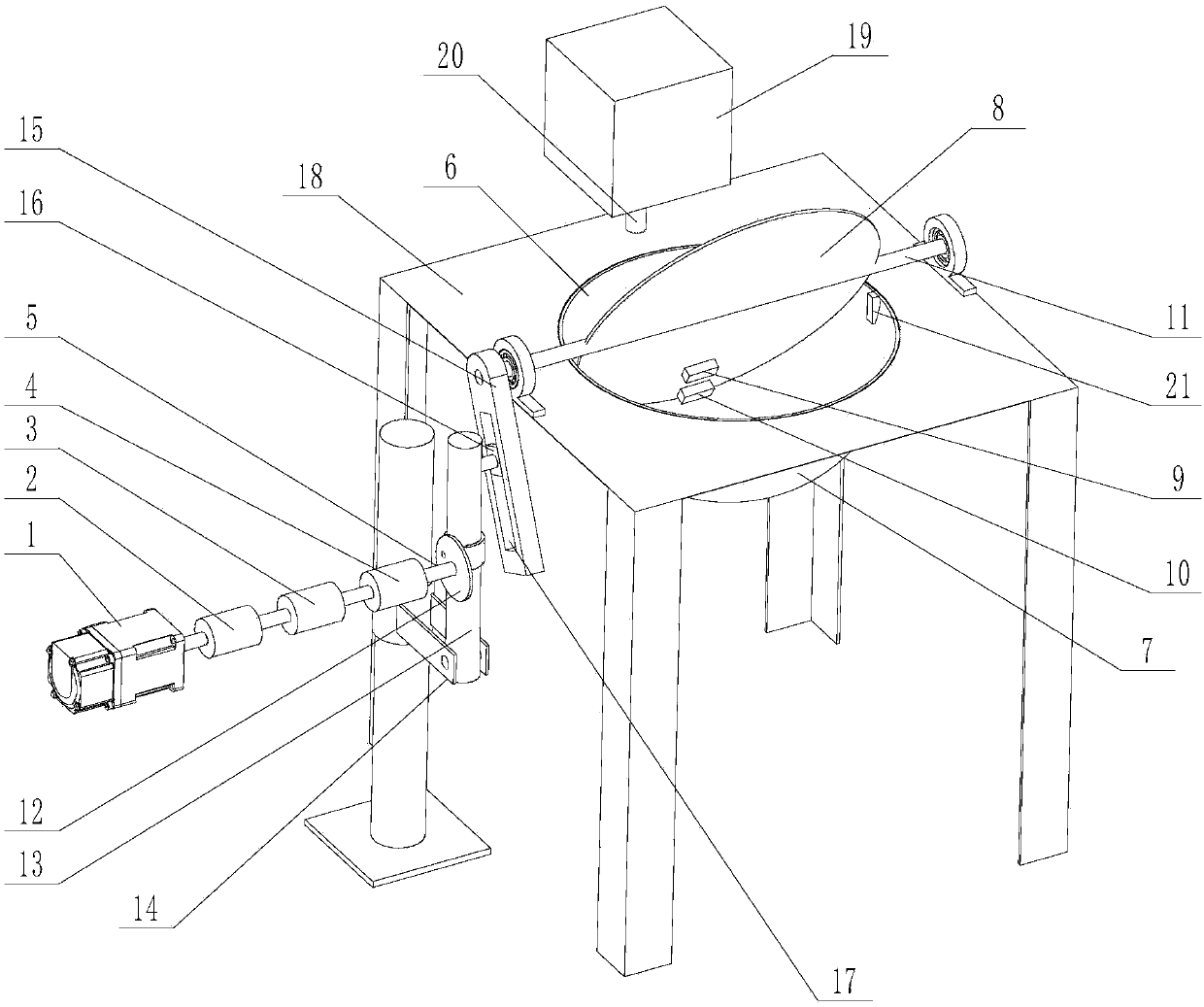

[0023] Such as figure 1 As shown, a tea processing equipment capable of improving the processing efficiency of spherical tea leaves includes a frame 18, a frying plate drive motor 1, a first coupling 2, a torque sensor 3, a second coupling 4, a drive shaft 11, a frying plate Pot 6, heating wire 7, frying plate 8, speed sensor 9, frying pan driving motor, frying pan rotating shaft, temperature sensor 10, air bag 19, air jet port 20, air jet control device and travel switch 21, the frying plate driving motor 1 is fixed on the frame 18, and the two ends of the frying pan 6 are provided with a frying pan rotating shaft, and the two frying pan rotating shafts are installed on the frame through bearing seats, and one of the frying pan rotating shafts is connected and fixed on the machine through a crank rocker mechanism. The frying pan driving motor on the frame; the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com