Tea leaf stir-frying device based on torque sensor and stir-frying method

A technology of torque sensor and temperature sensor, which is applied in the direction of instruments, tea processing before extraction, measuring devices, etc., can solve the problems of poor tea processing effect and lack of physical quantity, so as to prevent unstable quality, improve quality, and reduce roasting. The effect of this

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

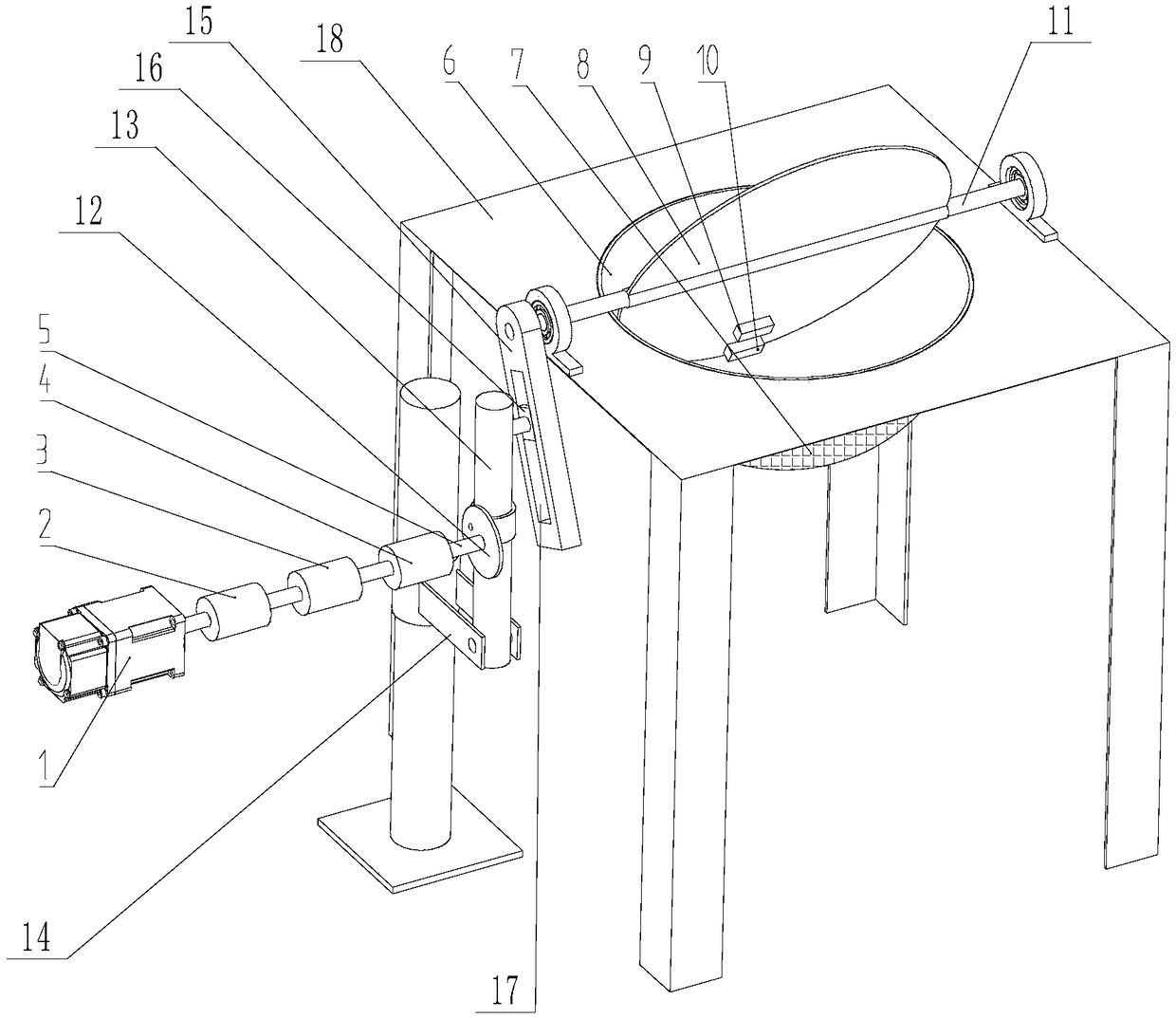

[0021] The present invention will be further explained below in conjunction with the drawings:

[0022] Such as figure 1 As shown, a tea frying equipment based on a torque sensor includes a frame 18, a drive motor 1, a first coupling 2, a torque sensor 3, a second coupling 4, a transmission shaft 11, a wok 6, and an electric heater The wire 7, the frying plate 8, the speed sensor 9, and the temperature sensor 10. The drive motor 1 and the frying pan 6 are all fixed on the frame 18, and the output shaft 5 of the drive motor 1 is connected to the first coupling 2 in turn The torque sensor 3 and the second coupling 4, the output shaft 5 of the second coupling 4 is connected to the transmission shaft 11 through a crank and rocker mechanism, the frying plate 8 is fixed on the transmission shaft 11, and the shape of the lower half of the frying plate 8 is It matches the shape of the wok 6 with a semicircle. When the drive motor 1 moves, the output shaft 5 of the second coupling 4 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com