Elevator device

A technology of elevators and lifting bodies, applied in transportation, packaging, elevators, etc., can solve the problems of large buffers, increased assumed collision speeds, and changes in inertial forces, and achieve the effect of longer suppression time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

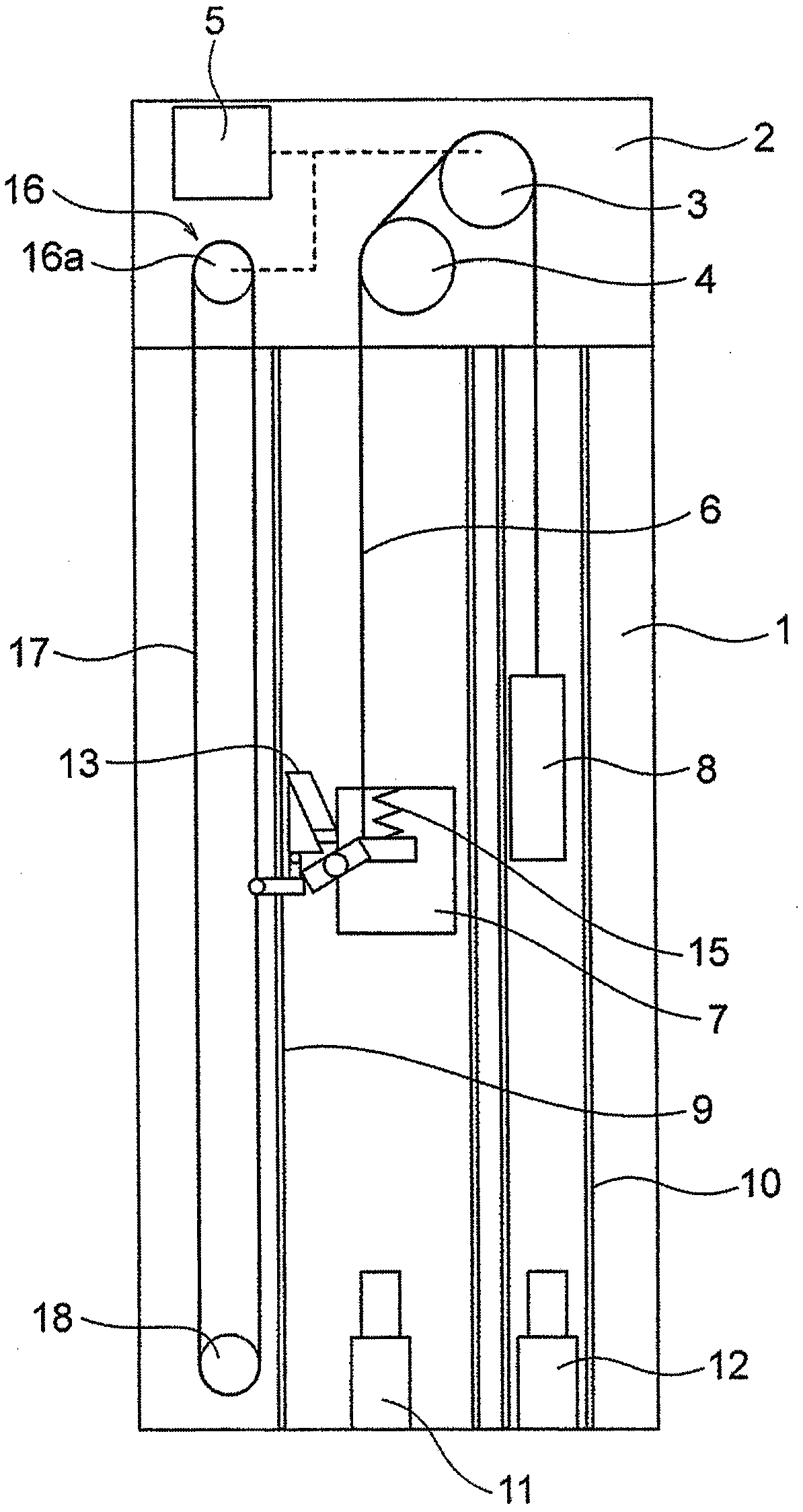

[0054] figure 1 It is a block diagram showing the elevator apparatus according to Embodiment 1 of the present invention. In the figure, a machine room 2 is arranged on the upper part of the hoistway 1 . A traction machine 3 and a deflector pulley 4 are arranged in the machine room 2 . The hoisting machine 3 has: a driving sheave; a hoisting machine motor that rotates the driving sheave; and a hoisting machine brake (electromagnetic brake) that brakes the rotation of the driving sheave.

[0055] The traction machine brake has: a brake sheave (drum or disc), which is coaxially combined with the drive sheave; a brake shoe, which contacts or separates from the brake sheave; and a brake spring, which directs the brake shoe toward the brake The brake wheel is pressed to apply the braking force; the electromagnet, which resists the brake spring, moves the brake shoe away from the brake wheel, thereby releasing the braking force.

[0056] A suspension body 6 is wound around the tra...

Embodiment approach 2

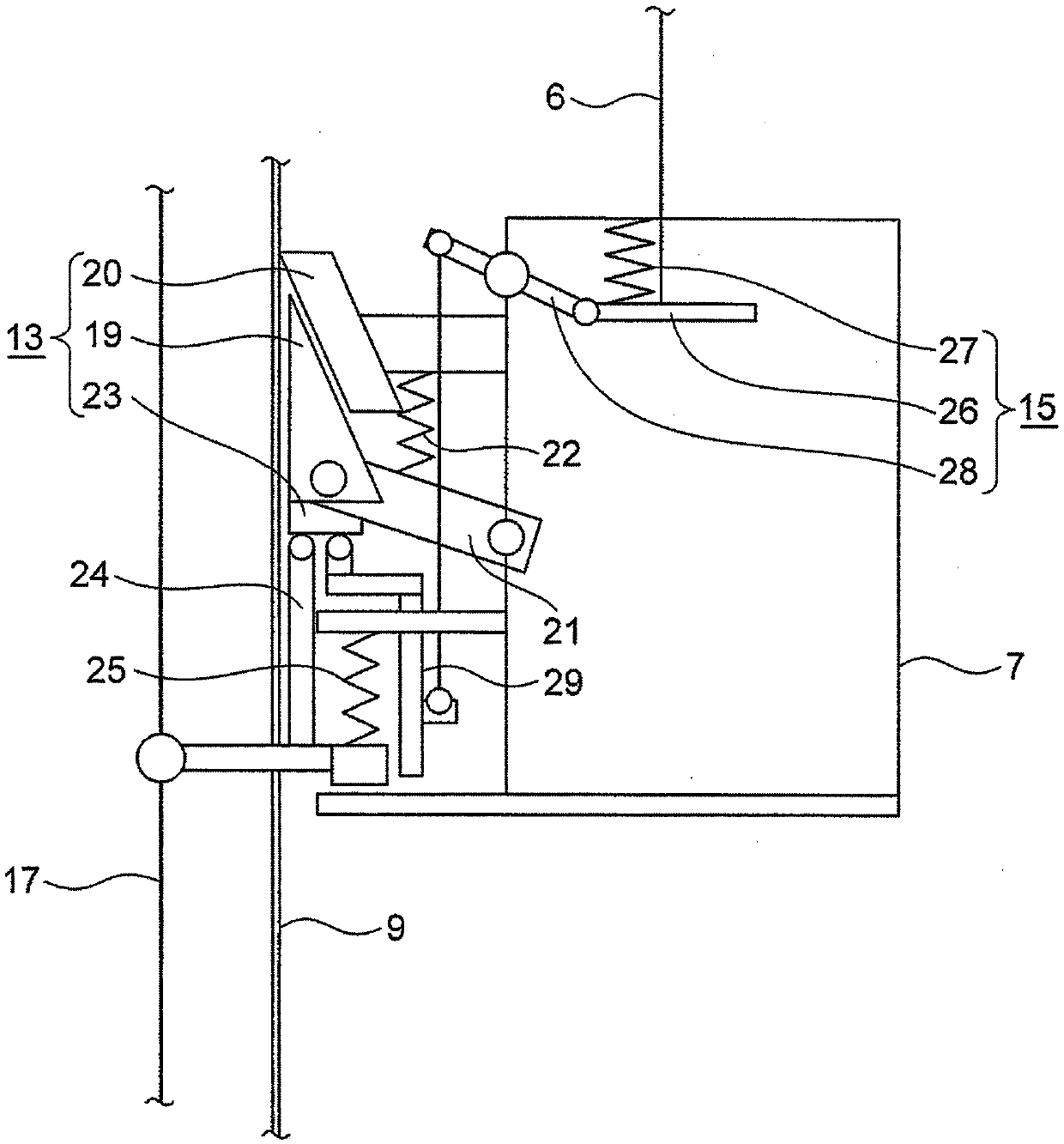

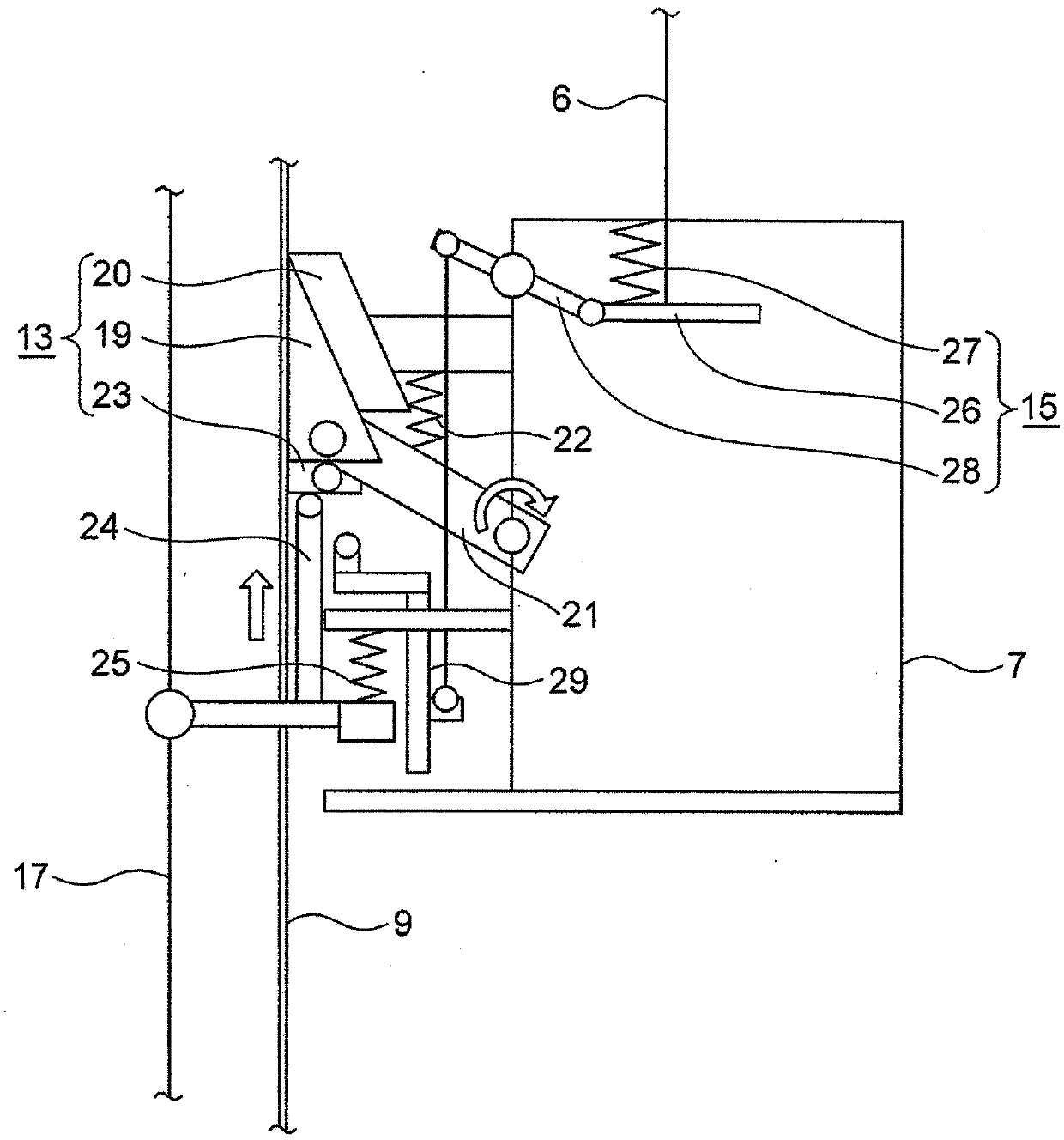

[0081] Next, Embodiment 2 of the present invention will be described. In addition, this second embodiment is the same as the above-mentioned first embodiment except for the parts described below. Figure 7 It is an enlarged view of the urging part receiving part of the structure in which the front end of the link retracts by compression in Embodiment 2, and is a view showing a locked state. Figure 8 It is an enlarged view of the urging part receiving part of the structure in which the front end of the link retracts by compression in Embodiment 2, and is a view showing a lock release state.

[0082] In Embodiment 1, instead of providing the vibration suppressing spring 22 on the link linked with the brake, a locking mechanism 33 is provided inside the urging part receiving part 23, and the first urging part 24 and the second urging part 24 are connected to each other. When the parts 29 are all in the initial position, due to the dead weight of the link of the locking mechanis...

Embodiment approach 3

[0089] Next, Embodiment 3 of the present invention will be described. In addition, this Embodiment 3 is the same as the said Embodiment 1 or 2 except the part demonstrated below. Figure 11 It is an enlarged view of the urging part receiving part 23 of Embodiment 3, and is a figure showing the state before engaging. Figure 12It is an enlarged view of the urging part receiving part 23 of Embodiment 3, and is a figure showing the time when the speed governor rope side is pulled up (the state in which the engaging mechanism operates).

[0090] In the contact portion between the brake member and the urging portion of Embodiment 1, a groove 41 is provided in the urging portion, and a link 40 is provided so that the urging portion can be freely displaced in an initial state. , when the force application part is displaced upward once and enters the brake receiving part, the connecting rod 40 rotates on the brake support part and engages with the groove 41 of the force application p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com