An Experimental Method for Predicting Coke Quality at Different Heights in Coke Oven

An experimental method and technology of coke quality, applied in the field of coking, can solve the problems of inability to accurately sample and obtain the performance difference of coke oven coke production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

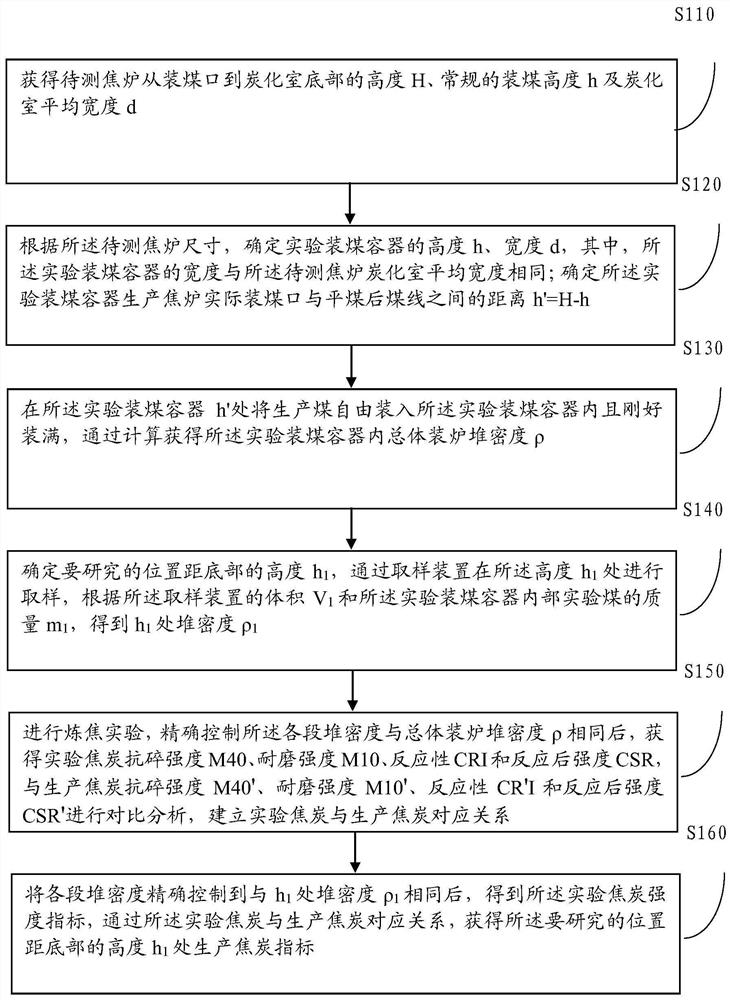

[0025] Such as figure 1 As shown, the embodiment of the present application provides an experimental method for predicting the quality of coke at different heights in the coke oven, including:

[0026] Step 110: Obtain the height H of the coke oven to be tested from the coal charging port to the bottom of the carbonization chamber, the conventional coal charging height h, and the average width d of the carbonization chamber;

[0027] Step 120: Determine the height h and width d of the experimental coal charging container according to the size of the coke oven to be tested, wherein the width of the experimental coal charging container is the same as the average width of the coking chamber of the coke oven to be tested; determine the The distance h'=H-h between the actual coal charging port of the coke oven produced by the experimental coal charging container and the coal line after leveling coal;

[0028] Further, in the method, the length of the coal charging container is gre...

Embodiment 2

[0047] In order to introduce the embodiment of the present invention more clearly, a 7.63-meter coke oven is taken as an example below.

[0048] Step 110: The height of the 7.63m coke oven from the coal charging port to the bottom of the carbonization chamber is about 9m, the conventional coal charging height is 7 meters, and the average width of the carbonization chamber is 590mm;

[0049] Step 120: Design the experimental coal charging container with a height of 9 meters and a width of 590mm, and the distance h'=2 meters between the actual coal charging port and the coal line after leveling coal;

[0050] Step 130: Build a belt conveyor on the platform 2 meters above the experimental coal charging container, and freely load the production coal into the container at a certain speed; stop coal loading when the production coal overflows from the upper part of the container, and use a scraper to scrape the coal above the container. Gently scrape off the coal sample along the edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com