Transmission for commercial vehicle

A technology for transmissions and commercial vehicles, which is applied in the direction of vehicle gearboxes, transmissions, gear transmissions, etc., can solve problems such as discomfort, and achieve the effect of reducing cost and structure consumption and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

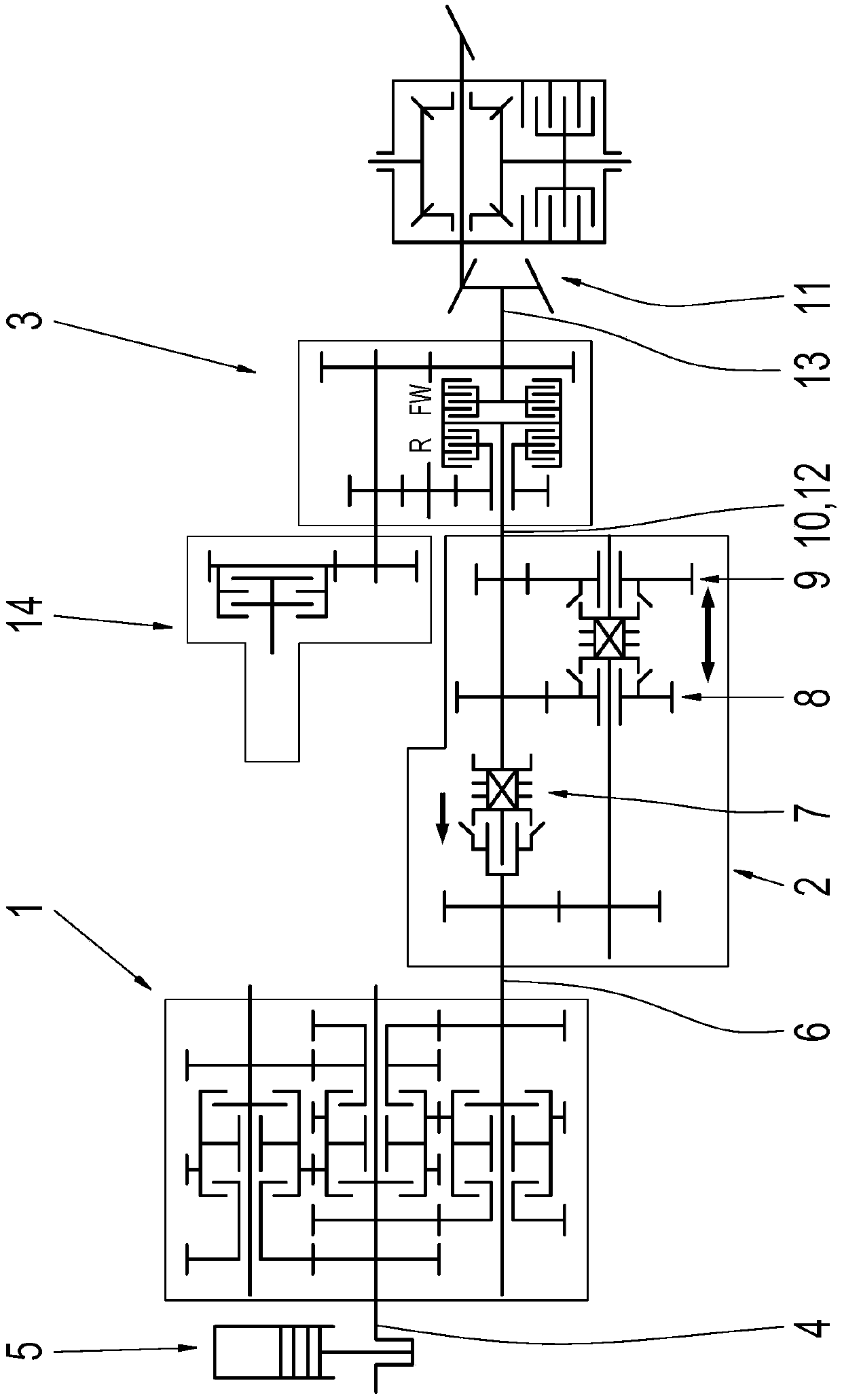

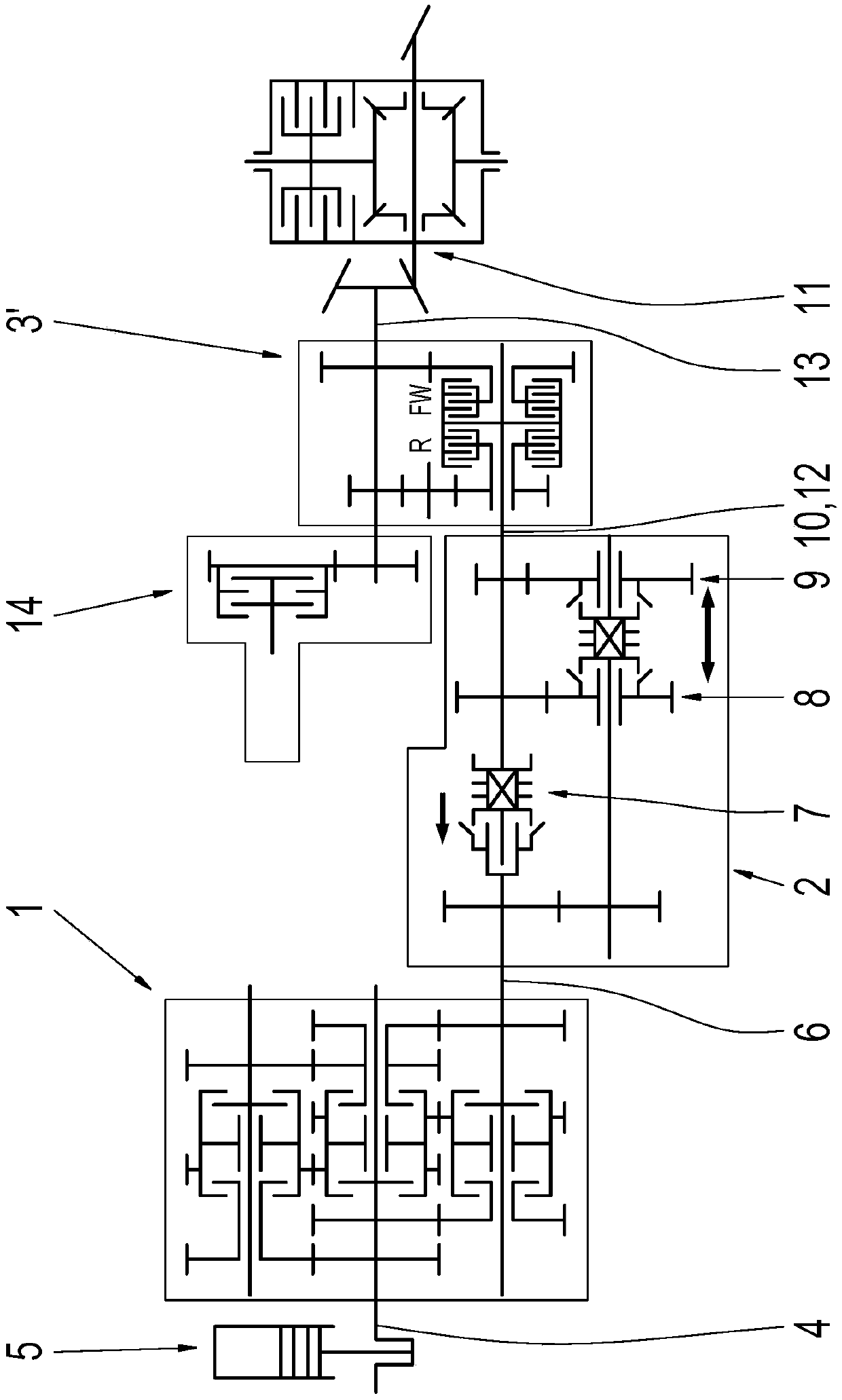

[0023] Transmission arrangements are used in commercial vehicles, in particular agricultural commercial vehicles, like for example tractors or the like.

[0024] The transmission arrangement has a power shift group 1 .

[0025] The power shift group 1 is followed by a synchromesh component 2 , followed by a power shiftable reversing group 3 , 3 ′.

[0026] Nine power-shiftable forward gears are realized by means of the power-shift gear group 1 embodied as a 9-stage power-shift gear group 1 . At the same time, the drive shaft 4 of the power shift group 1 is rotatably driven by the vehicle engine 5 .

[0027] The output 6 of the power shift group 1 drives the synchromesh part 2 with three synchronous gears, wherein the second synchronous gear 7 is a direct through-drive synchronous gear which is used in the main operating range of the transmission arrangement. The first synchronous gear 8 and the third synchronous gear 9 are indirectly driven.

[0028] The drive of the shift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com