Hanging device for film type wall heating surface

A hanging device and membrane wall technology, applied in lighting and heating equipment, components of steam boilers, steam boiler accessories, etc. The effect of stability, prolonging service life and avoiding cracking accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

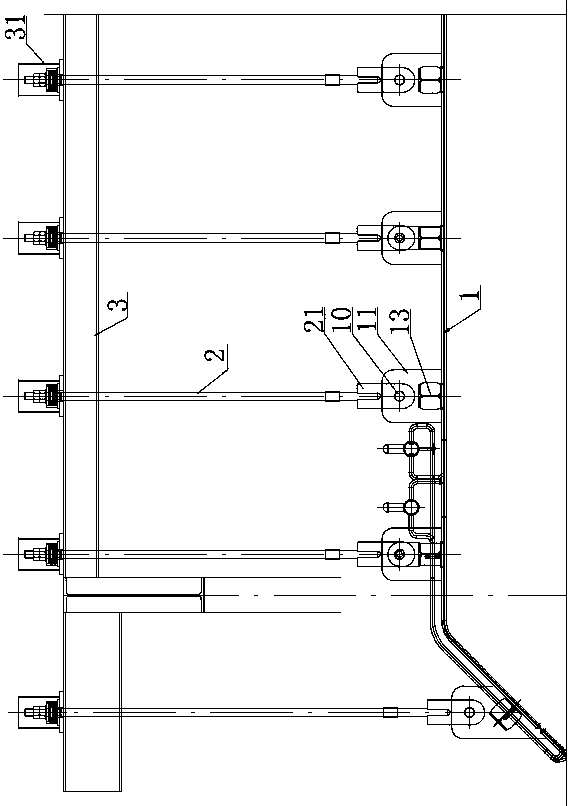

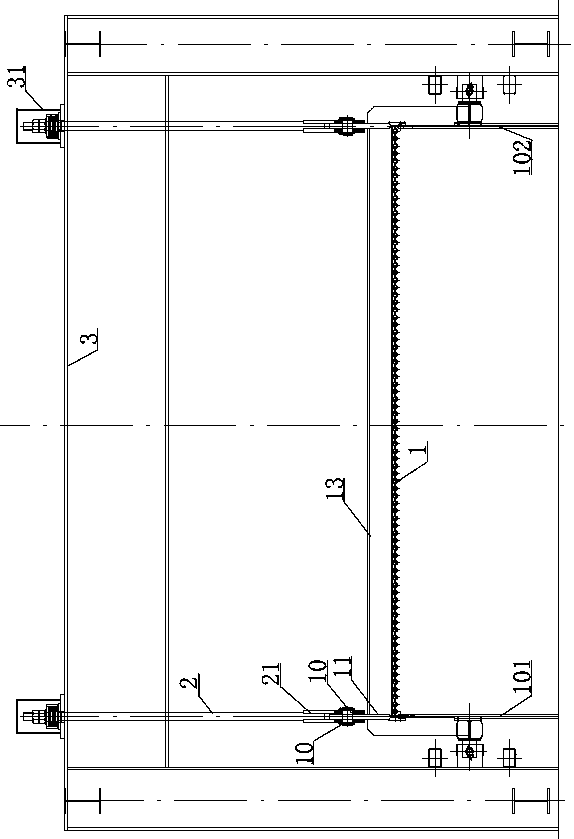

[0015] Such as figure 1 , figure 2 , image 3 As shown, the hanging device of the heating surface of the membrane wall includes: a plurality of suspension rods 2 arranged on the top of the heating surface 1 of the membrane type wall, the top of each suspension rod 2 is supported on the bearing bracket 3, and each suspension rod 2 The lower ends of both are connected to the heating surface 1 of the membrane wall. The suspenders 2 are arranged in pairs, and each pair of suspenders 2 is respectively arranged on the top of the left wall 101 and the right wall 102 of the membrane wall heating surface 1, and the left wall 101 and the right wall 102 are the transverse direction of two walls.

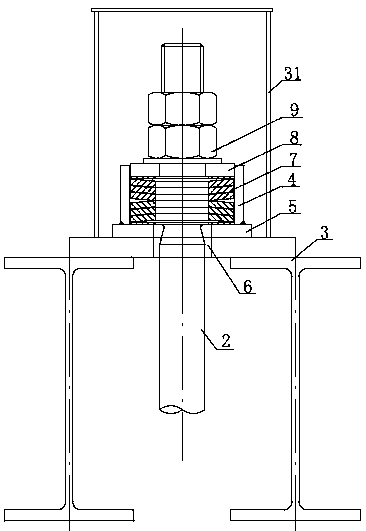

[0016] In this embodiment, the connection structure between each suspender 2 and the bearing bracket 3 includes: a spring seat 4, the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com