On-line eddy current monitoring method for longitudinal tear damage of wire rope conveyor belt

A longitudinal tearing, wire rope technology, applied in conveyor objects, conveyor control devices, measuring devices, etc., can solve the problems of small accident alarm advance, high detection cost, poor detection accuracy, etc., to avoid tearing accidents, The effect of high sensitivity and fast monitoring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

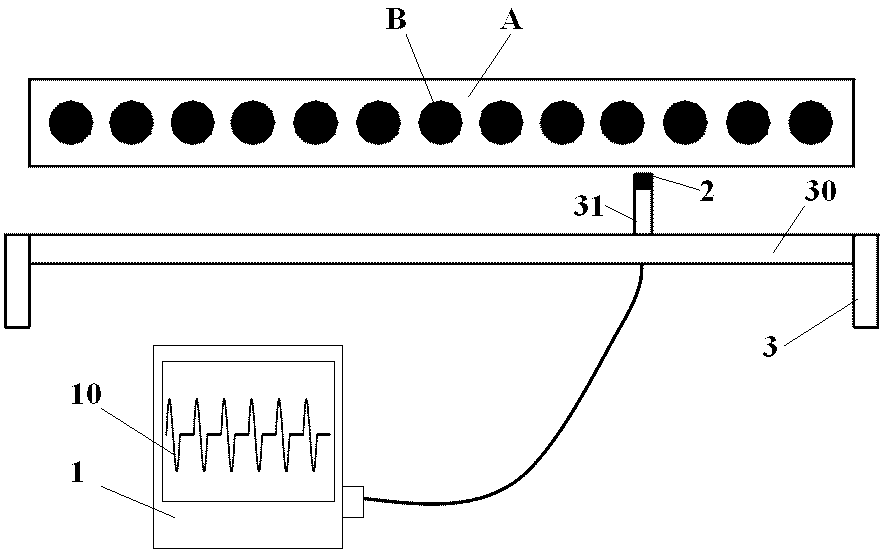

[0017] figure 1 In the shown first embodiment, the on-line eddy current monitoring device for longitudinal tear damage of the steel cord conveyor belt includes an eddy current detector 1, an eddy current detection probe 2, and a probe scanning device 3. It is characterized in that the probe scanning device 3 The scanning track 30 is linear, and the length of the scanning track 30 is the same as the transverse width of the inspected wire rope conveyor belt. There is a probe bracket 31 on the scanning track 30, and the probe bracket 31 is a variable-length telescopic bracket. The probe bracket 31 The eddy current detection probe is fixed at the top, and the probe holder 31 can move back and forth along the scanning track 30 under the control of the probe scanning device 3 .

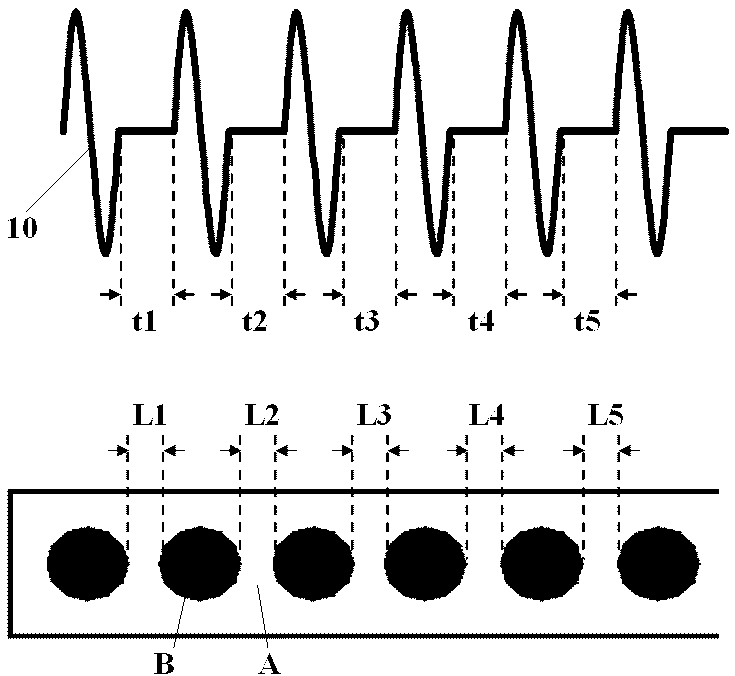

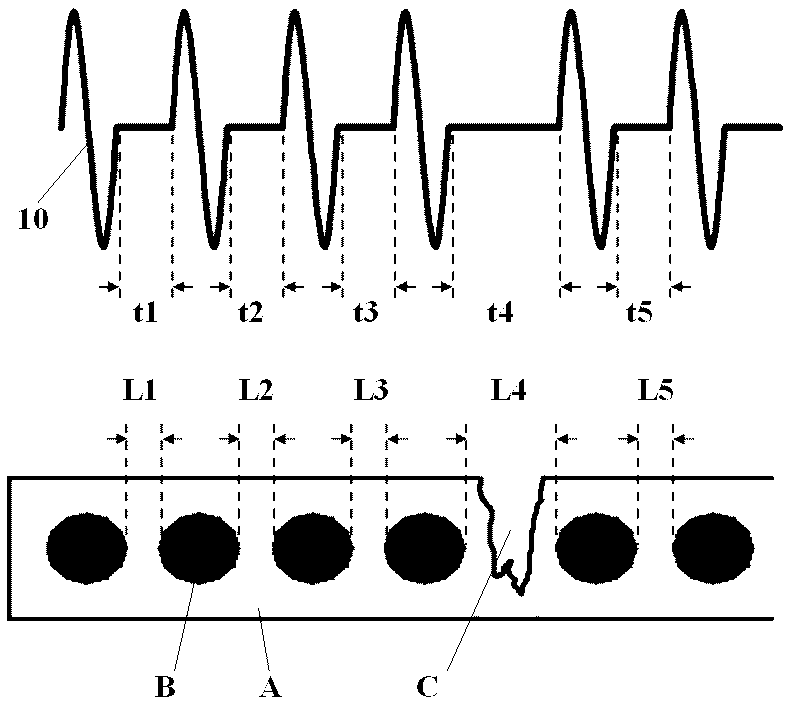

[0018] figure 2 , image 3 In the first embodiment shown, the online eddy current monitoring method for longitudinal tear damage of the steel wire rope conveyor belt is characterized in that the probe sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com