Punching and static pressure pile driving method

A technology of static pressure pile driver and punching and digging, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of limiting the application and promotion of static pressure pile reinforcement foundation, increasing construction links and costs, and failing to meet the design of the pile end. problems such as elevation, to achieve the effect of strengthening the promotion and application value and advanced nature, reducing the effect of soil extrusion, and overcoming the shortcomings of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

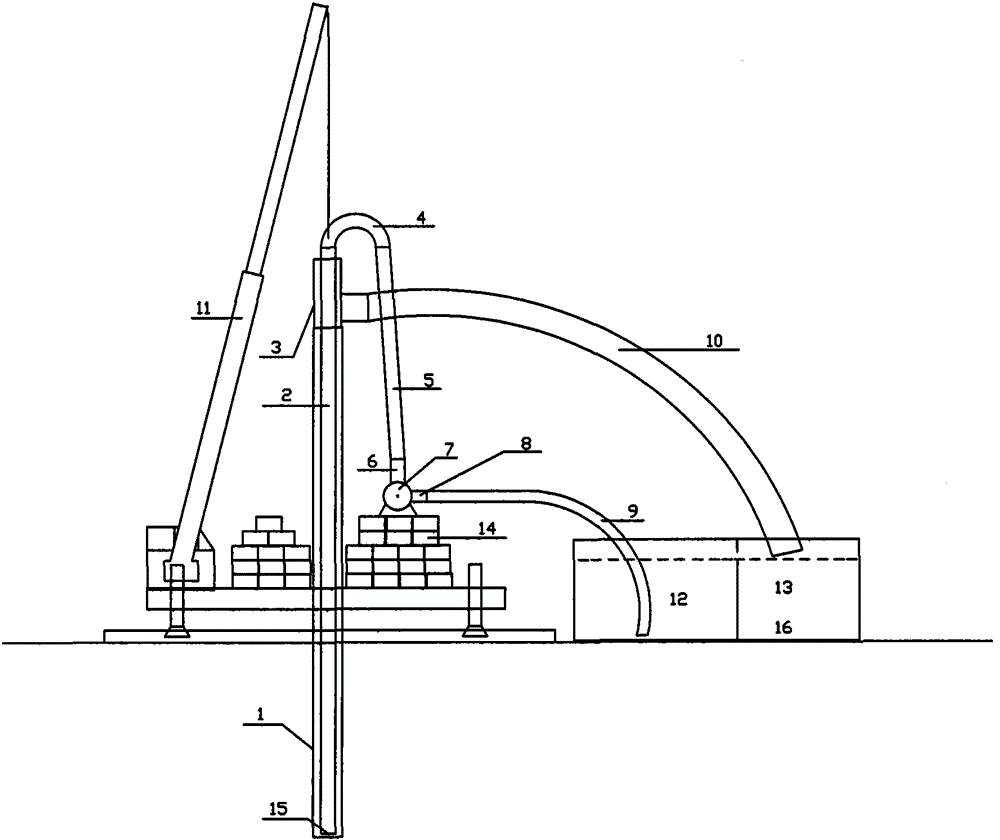

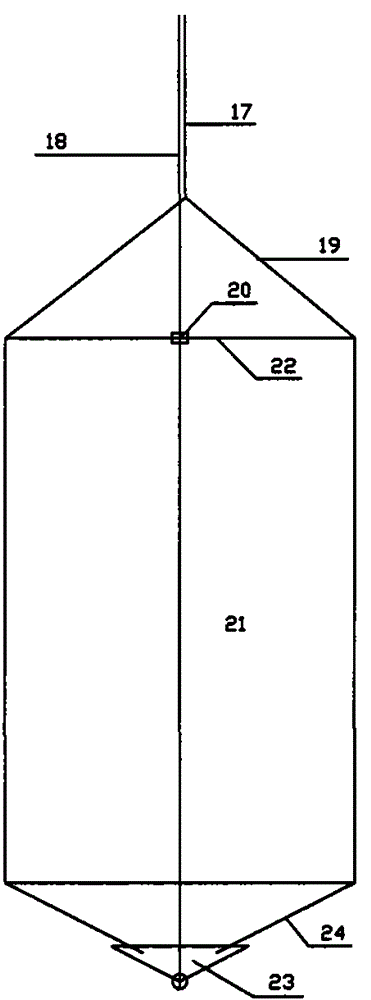

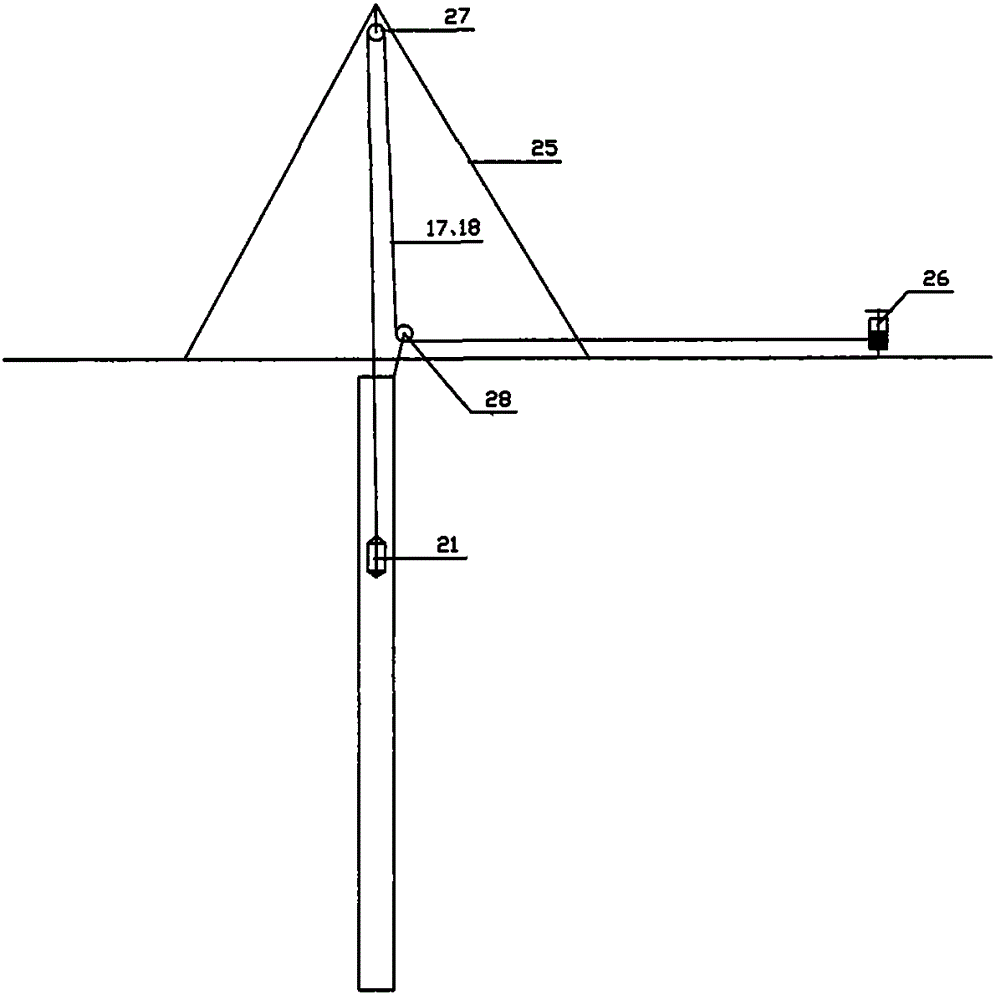

[0016] Combine below Figure 1-Figure 3 , the present invention is described in detail.

[0017] Punching and digging static pressure pile driving method, including construction equipment layout and operation technology and technology:

[0018] (1) Layout of pile driving equipment

[0019] The high-pressure water pump 7 and its supporting electrical equipment are installed on the static pile driver or the static pile driver counterweight 14 at a suitable place, the mud collection overflow pipe 3 is installed on the top of the pipe pile 1 to be pressed, and the mud sedimentation tank 13 and the water tank 12 are arranged On the ground near the reachable range of the boom 11 of the static pile driver, which does not affect the construction of the pile, and where the deposited soil is easy to remove, the high-pressure water pump water outlet 6 and the water inlet 8 are connected to the high-pressure water supply hose 5 and the high-pressure water pump water inlet hose 9 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com