Automatic torsion spring assembling machine for illuminating lamp production

A technology for lighting lamps and assembling machines, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of inability to meet the development trend of high efficiency, high quality and low cost, laborious manual operation, and high labor costs. High assembly quality, reduced labor costs, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] The present invention will be further described in detail below in conjunction with the drawings.

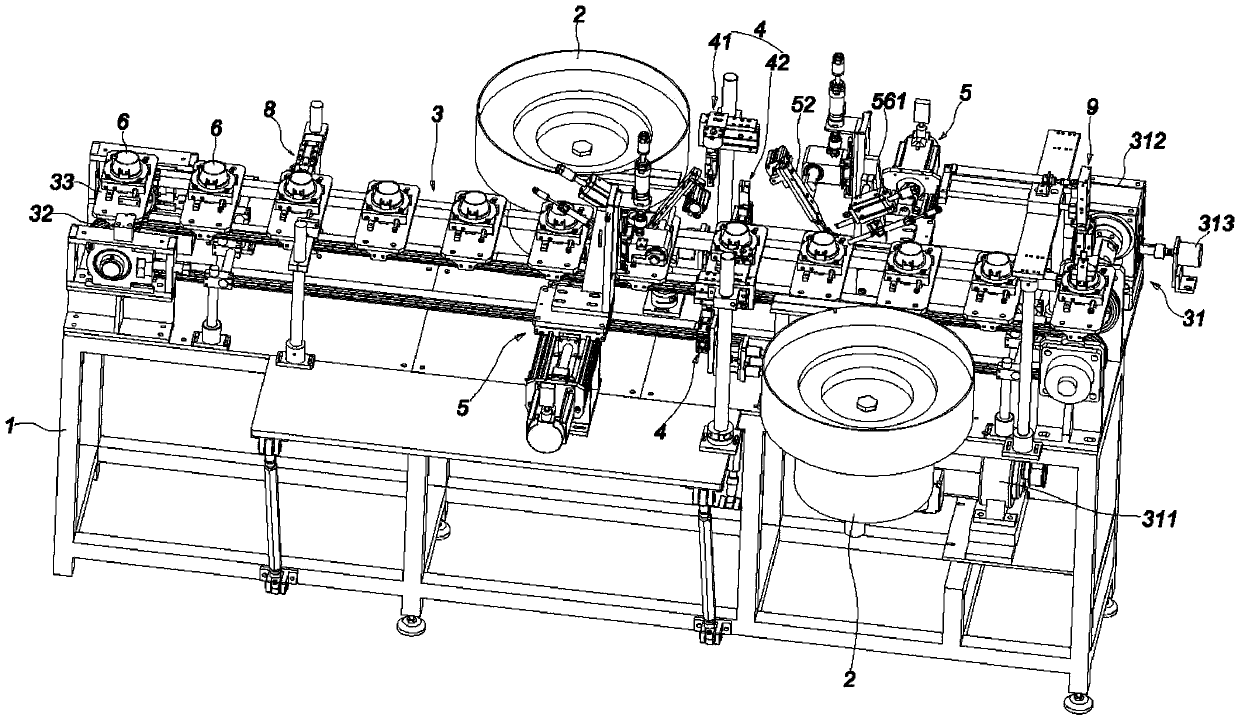

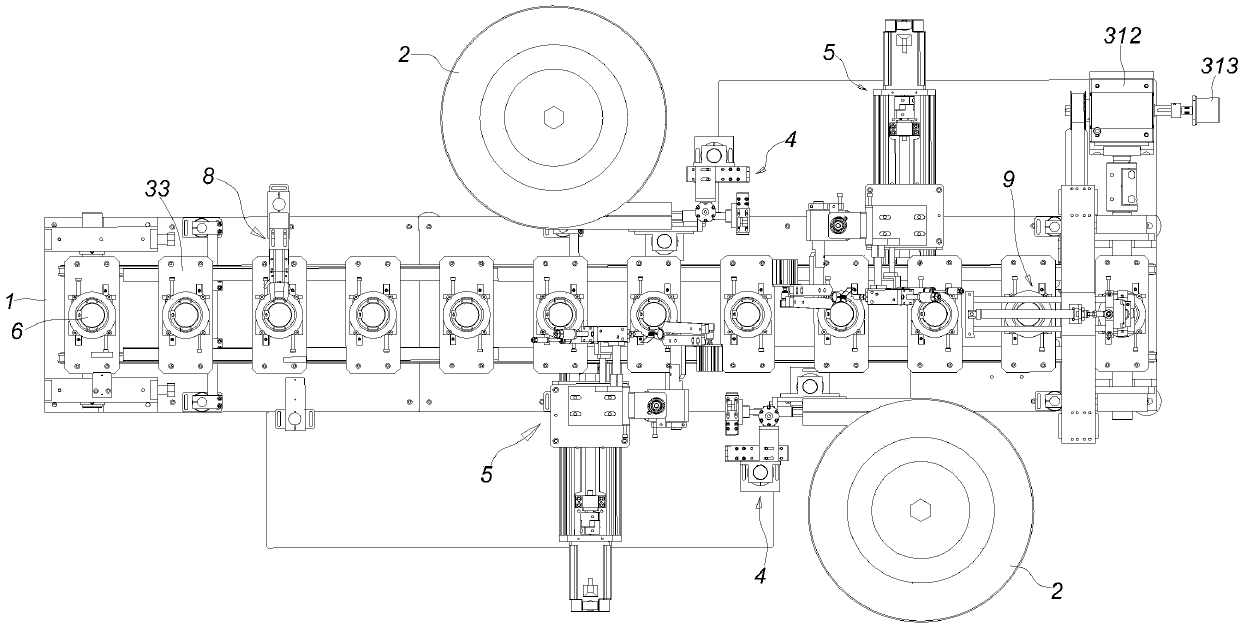

[0034] Figure 1~13 It schematically shows an automatic torsion spring assembly machine for the production of lighting lamps according to an embodiment of the present invention.

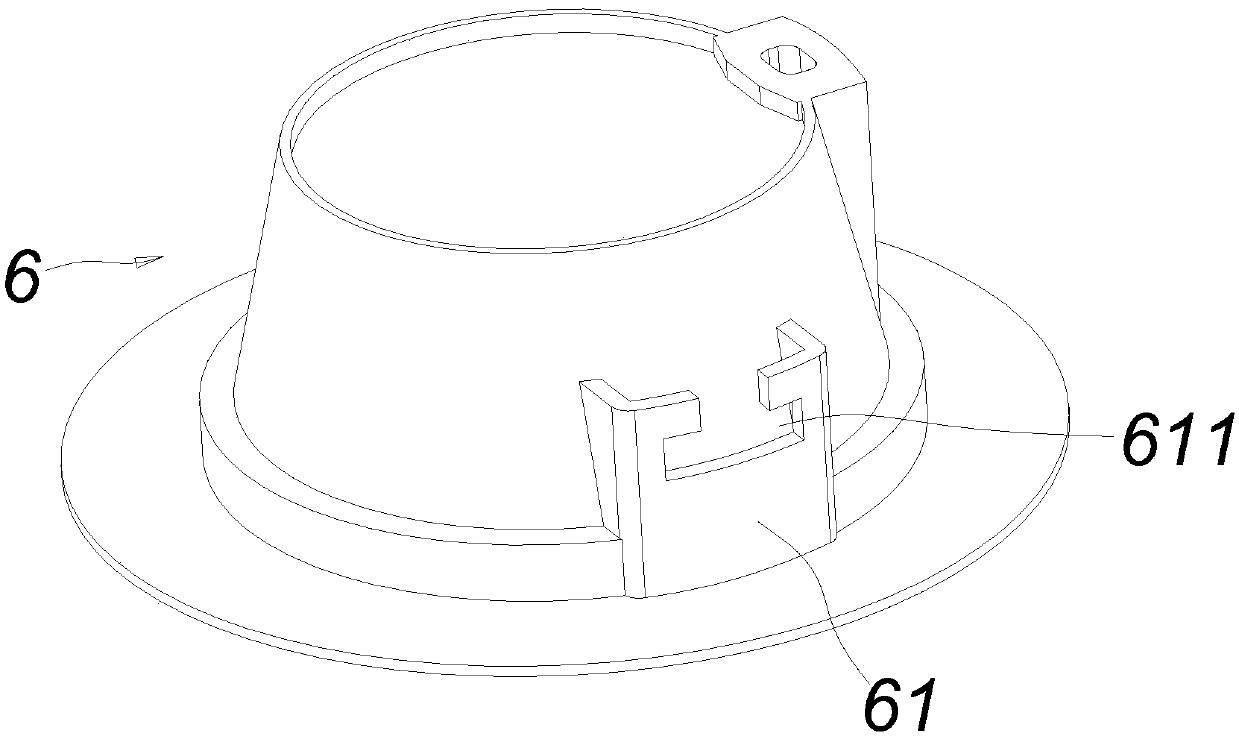

[0035] Such as Figure 1~13 As shown, the automatic torsion spring assembly machine for the production of lighting lamps includes a frame 1, a torsion spring feeding device 2, a lamp conveying device 3, a torsion spring conveying device 4, a torsion spring installation mechanism 5, a lamp position correction device 8 and a lamp outlet 料装置9。 Material device 9. The torsion spring installation device 5, the torsion spring feeding device 2, the lamp conveying device 3 and the torsion spring conveying device 4 are all installed in the frame 1. The torsion spring conveying device 4 cooperates with the torsion spring feeding device 2 and the torsion spring mounting device 5 respectively. The torsion spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com