Car front safety anti-collision beam

A technology of anti-collision beams and automobiles, applied in the direction of vehicle safety arrangements, vehicle components, bumpers, etc., can solve the problems of insufficient rigidity, stress concentration, simplicity, etc., and achieve improved anti-collision performance, avoid stress concentration, and good transmission effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

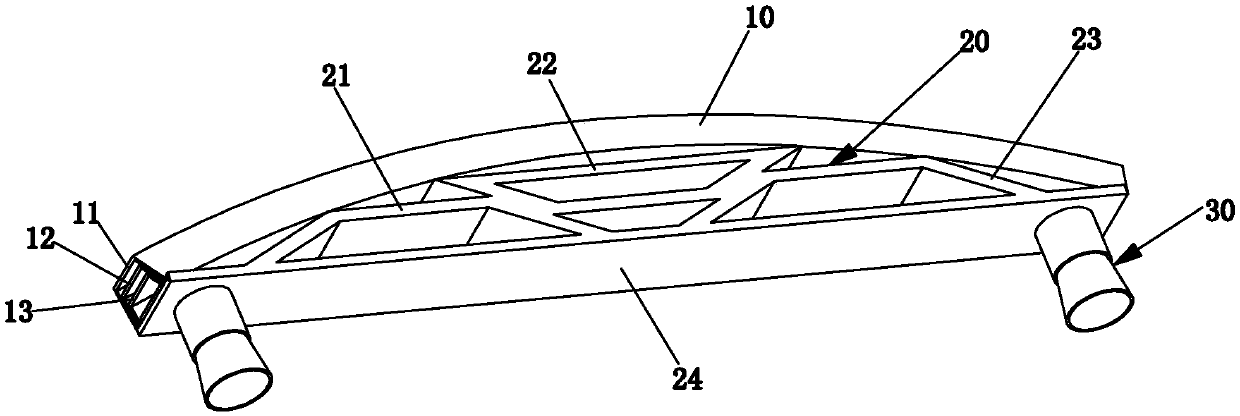

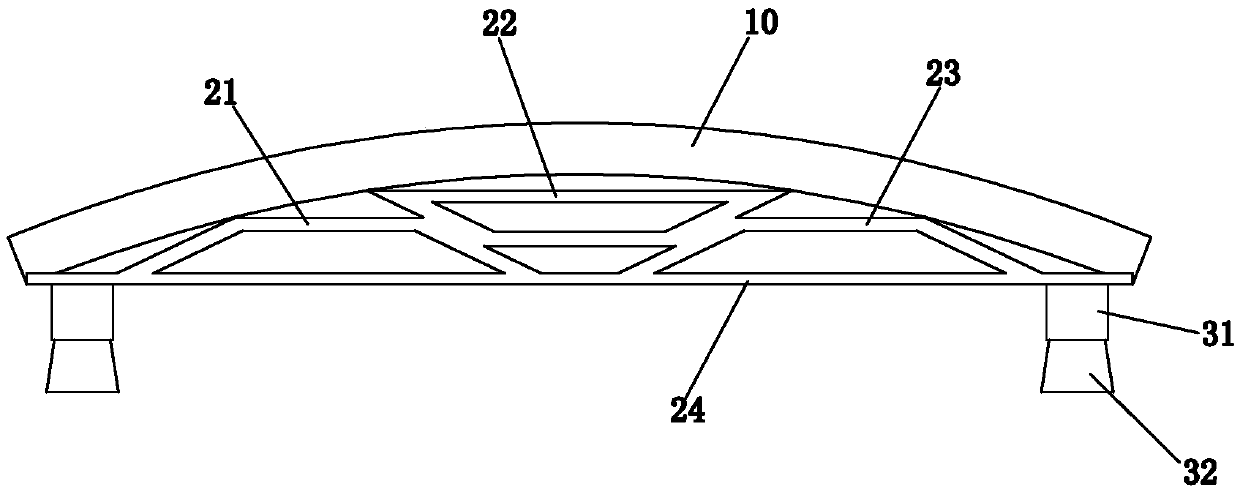

[0031] Please check Figure 1 to Figure 4 , a preferred embodiment of an automobile front safety anti-collision beam, said a kind of automobile front safety anti-collision beam, which includes a body 10, a truss 20 and an energy-absorbing box 30 affixed to the truss 20.

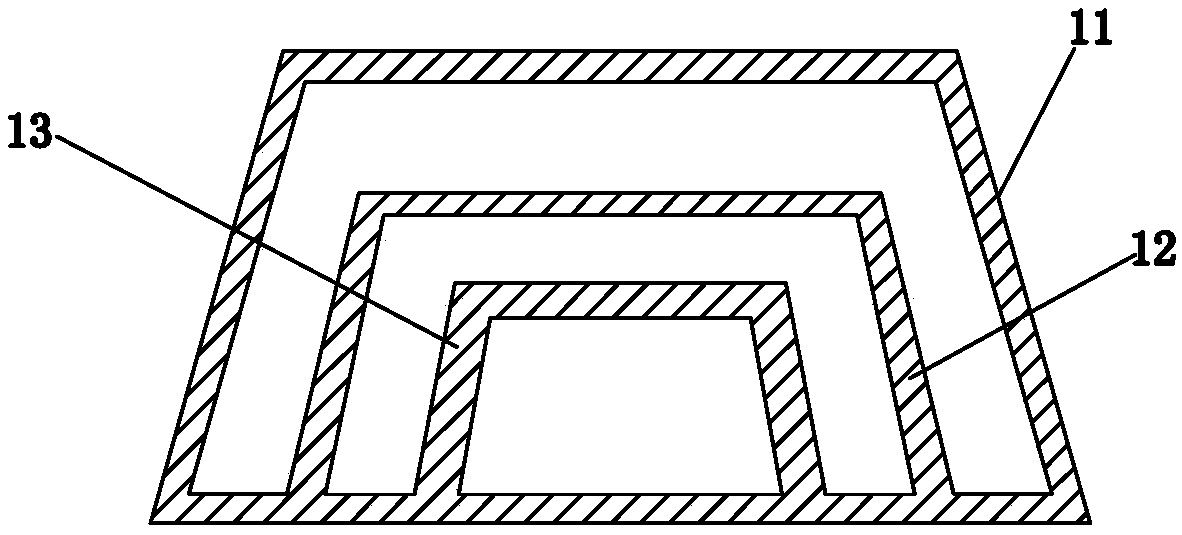

[0032] like figure 2 As shown, the cross section of the body 10 includes a fourth trapezoidal body 11, a fifth trapezoidal body 12 and a sixth trapezoidal body 13, the fifth trapezoidal body 12 is located in the fourth trapezoidal body 11, and the sixth trapezoidal body 13 is located in the fifth trapezoidal body. In the body 12, and the bases of the three trapezoids are on the same straight line, when the fourth trapezoid 11 is hit, the fourth trapezoid 11, the fifth trapezoid 12 and the sixth trapezoid 13 are superimposed to improve the height of the body 10. stiffness. And there are gaps among the fourth trapezoidal body 11 , the fifth trapezoidal body 12 and the sixth trapezoidal body 13 . The cross s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com