Multi-rope connecting method of steel cable belt joint

A steel wire rope core and steel wire rope technology, applied in belt fasteners, belts/chains/gears, conveyors, etc., can solve problems such as weak belt connections and safety risks, and achieve self-connection unevenness and meet the needs of safe use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

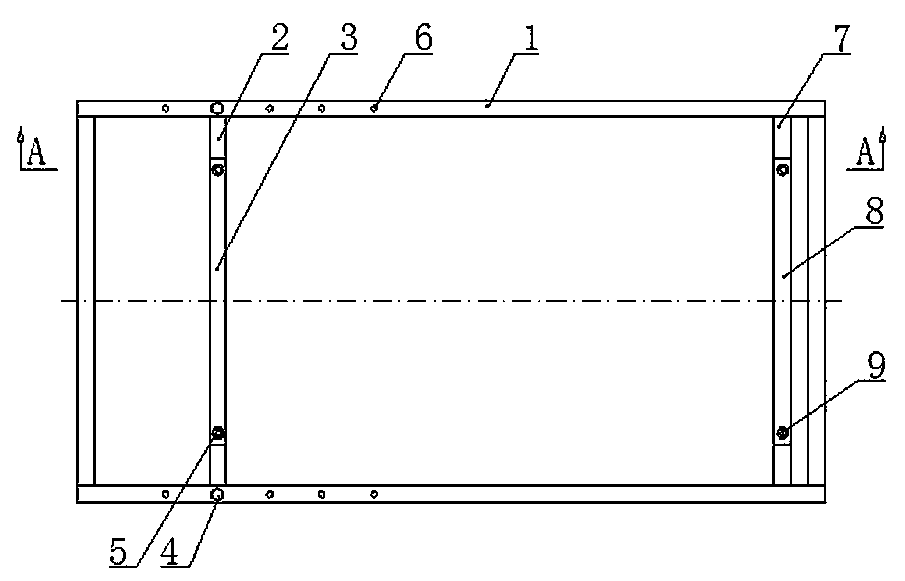

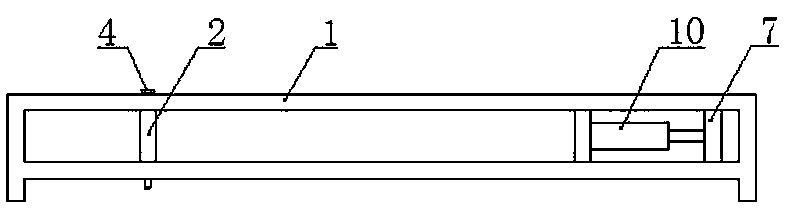

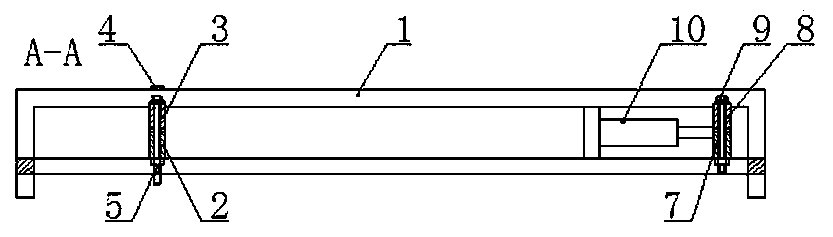

[0027] see Figure 1-Figure 4 , the fixed frame includes a frame body 1, the frame body 1 is a frame structure composed of four rectangularly distributed columns and four beams, a fixed clip is installed on the upper left end of the frame body 1, and the fixed clip includes a fixed clip bottom The beam 2 and the fixed clamp platen 3 arranged on it are connected with the fixed clamp bottom beam 2 with the fixed clamp screws 5 at both ends of the fixed clamp clamp plate 3; the two ends of the fixed clamp bottom beam 2 are fixed on the On the frame body 1; the right end of the frame body 1 is provided with movable clips having the same structure as the fixed clips and used correspondingly, the movable clips include the movable clip bottom beam 7 and the movable clip pressing plate 8 arranged on it The two ends of movable clip pressing plate 8 are connected with movable clip bottom beam 7 with movable clip screw 9. A jack 10 is respectively housed on both sides of the frame body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com