LED luminaire device for factory lighting

A technology for LED lamps and factory lighting, applied in lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of inconvenient lamp installation, cumbersome installation operations, electric shock accidents for staff, etc., to avoid electric shock accidents and installation. The process is safe and convenient, and the effect of preventing the danger of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings of the embodiments of the present invention.

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 shown;

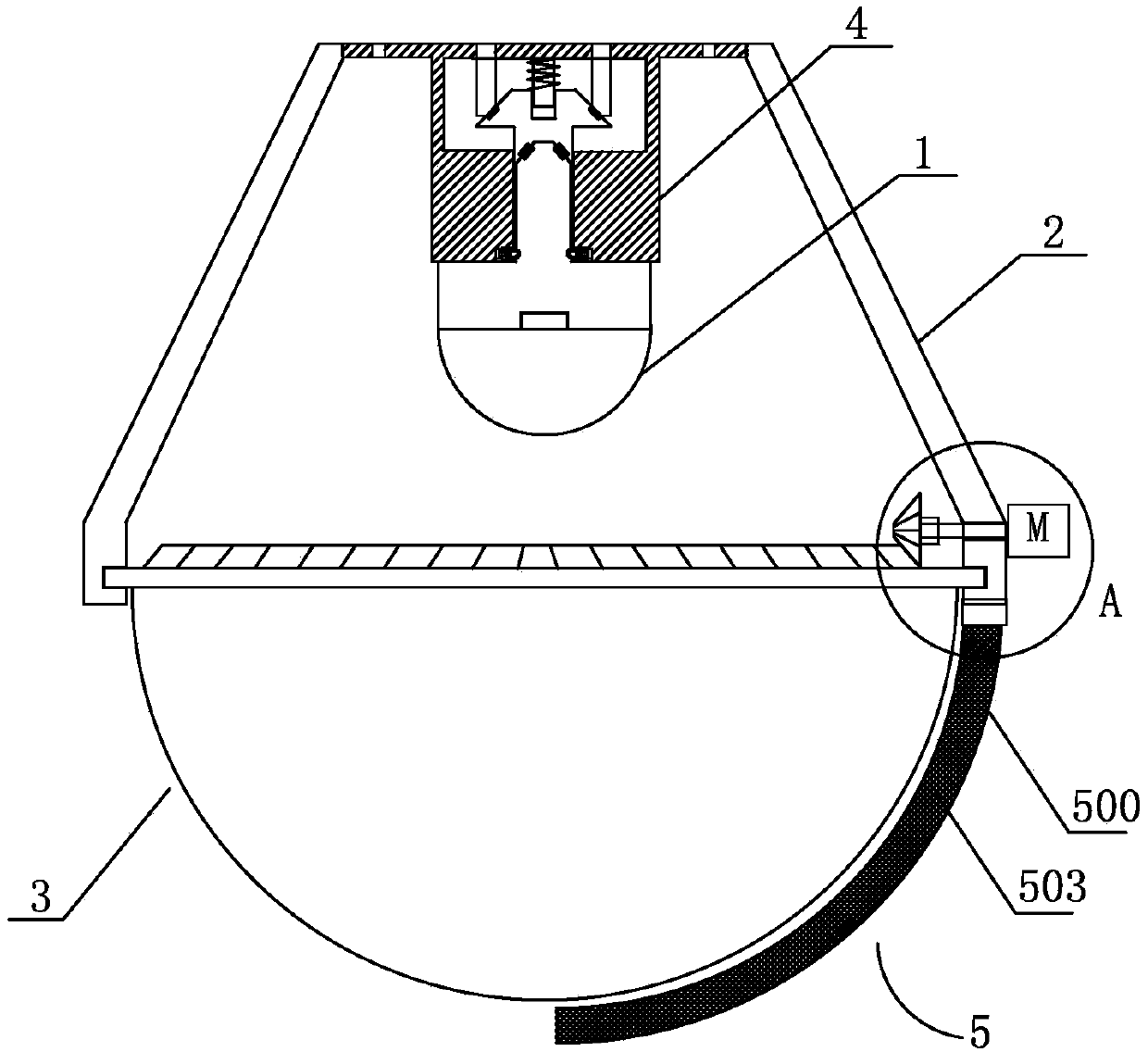

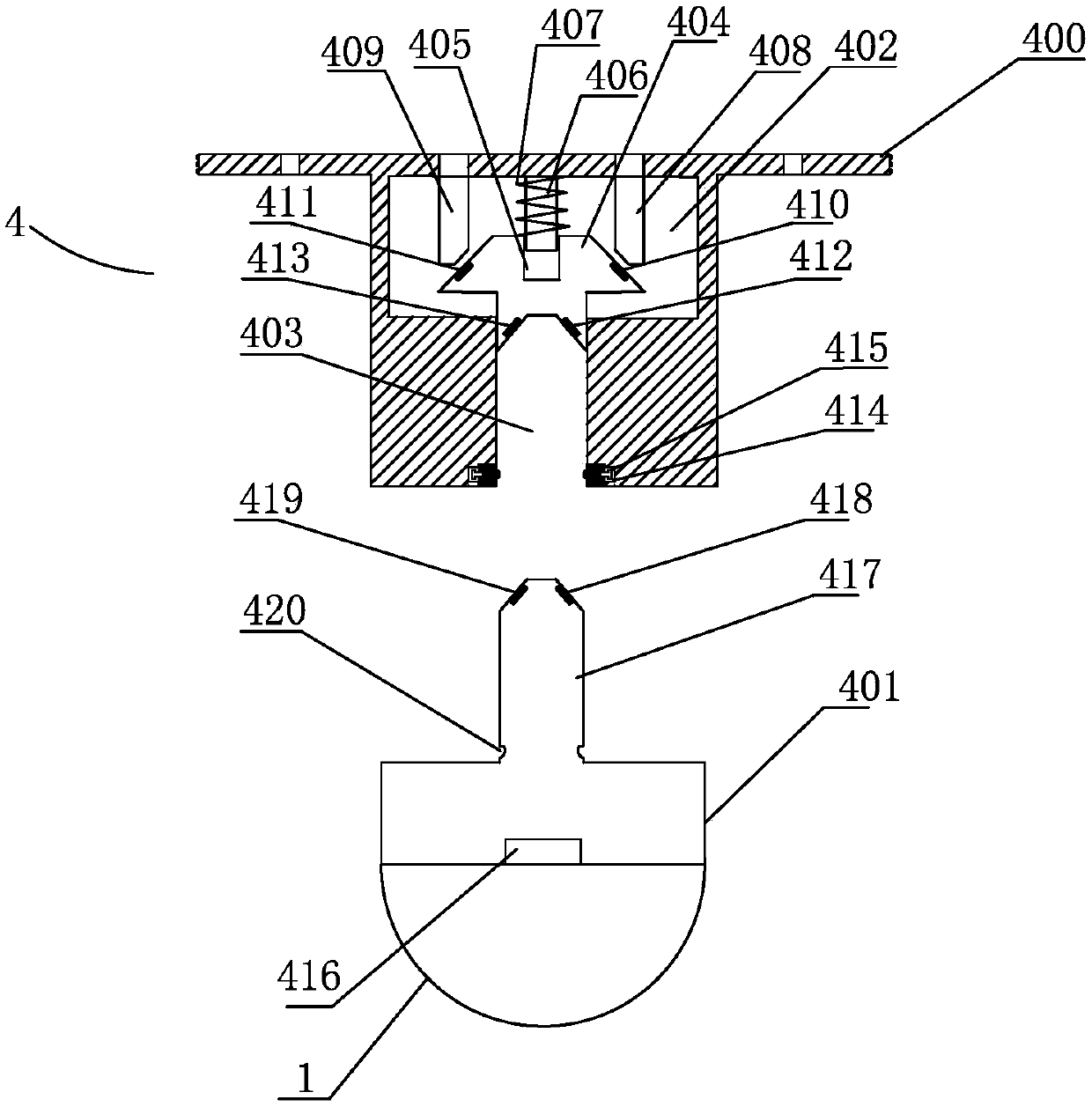

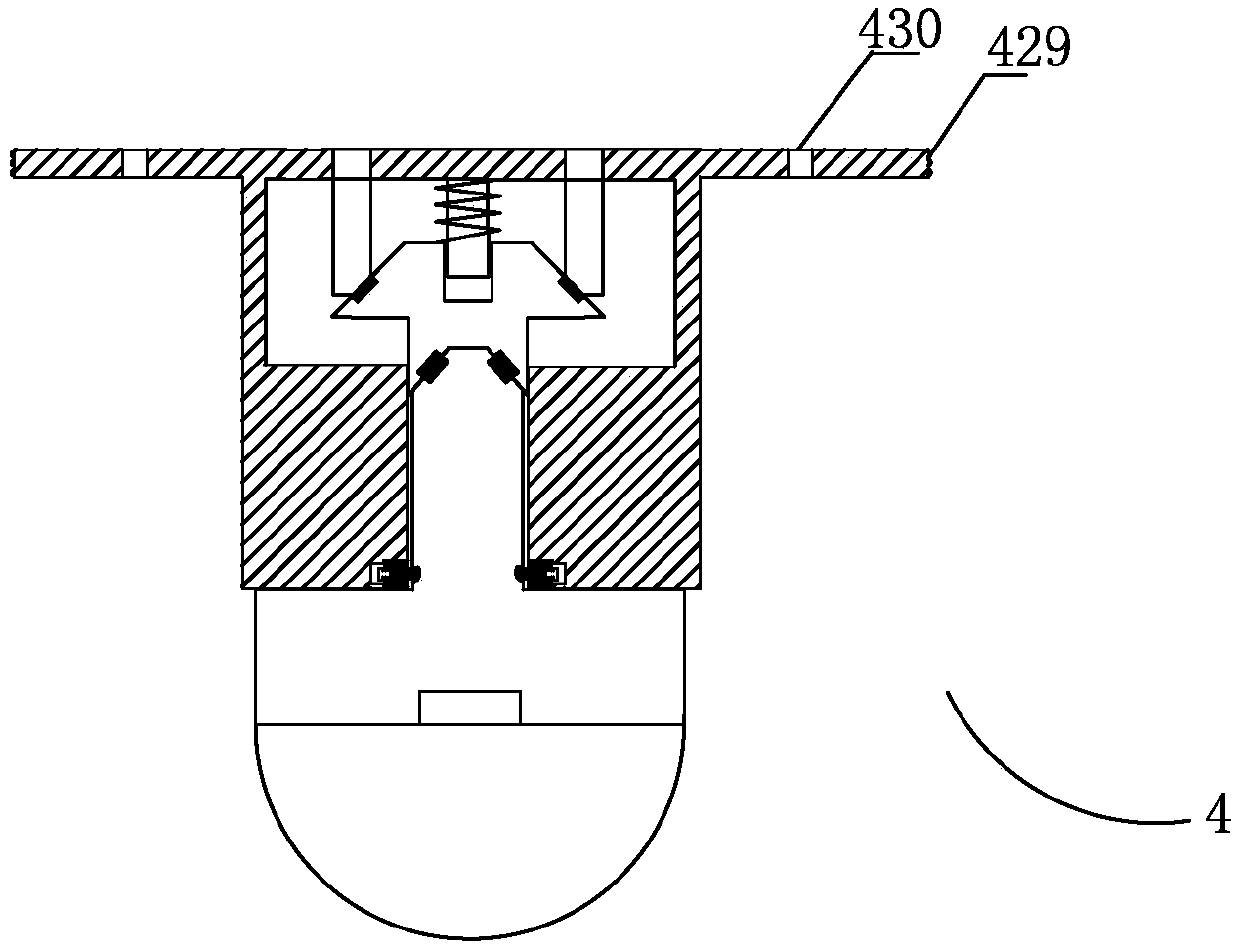

[0025] The technical solution adopted by the present invention is to provide an LED lighting device for factory lighting with the following structure, which includes an LED lamp 1, a sunshade plate 2, a lampshade 3, a lamp holder mechanism 4 and a dust removal mechanism 5, the The LED lamp 1 is connected to the lamp holder mechanism 4, one end of the light shielding plate 2 is connected to the lamp holder mechanism 4, the other end of the light shielding plate 2 is rotatably connected to the lampshade 3, and the dust removal mechanism 5 is connected to the bottom of the light shielding plate 2;

[0026]The lamp holder mechanism 4 includes a base 400 and a connecting seat 401, the base 400 is provided with an accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com