Automobile glass front and back door bracket installing tool

A technology for glass brackets and tooling installations, applied in manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve problems such as affecting product quality and glue spillage, saving maintenance costs, preventing defective products, and ensuring quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

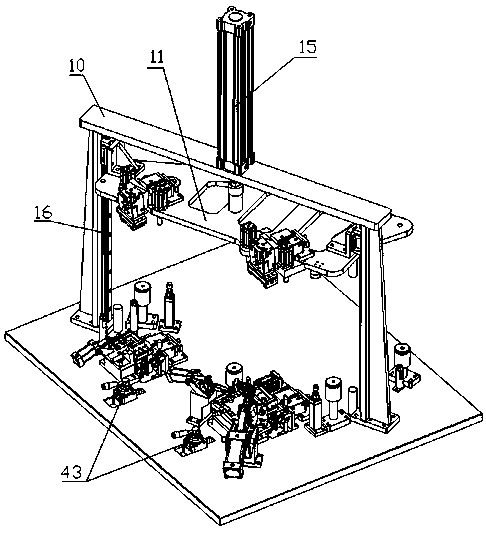

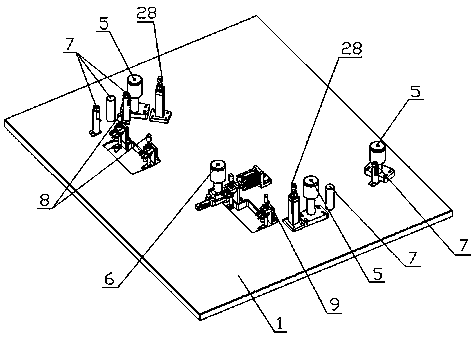

[0036] As shown in the drawings, the present invention includes a workbench 1, a glass positioning device, a pair of heating and constant temperature devices 2, a first glass bracket pressing device 3 and a second glass bracket pressing device 4,

[0037] The glass positioning device includes a glass supporting and limiting component and a glass pressing component.

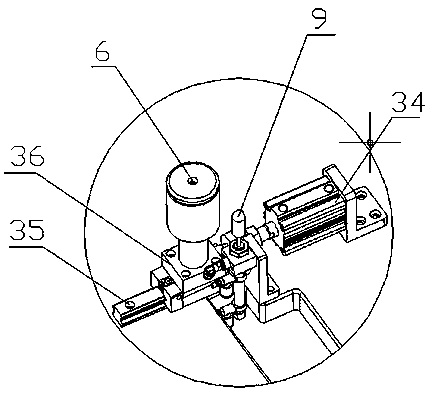

[0038] The glass support limit assembly includes at least three fixed limit columns 5, movable limit columns 6, at least five fixed support columns 7, a pair of first support cylinders 8, a pair of second support cylinders 9 and a pair of connecting plate supports Post 28,

[0039] At least three fixed limit columns 5 are detachably installed on the workbench 1, movable limit columns 6 are slidably installed on the workbench 1, at least five fixed support columns 7 are fixedly installed on the workbench 1, and a pair of first The support cylinder 8 and a pair of second support cylinders 9 are respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com