Diagnostic method for large-scale blast furnace core stacking

A diagnostic method and blast furnace technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of lack of versatility, operator's furnace condition diagnosis and furnace condition adjustment, etc., and achieve the impact of furnace conditions. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

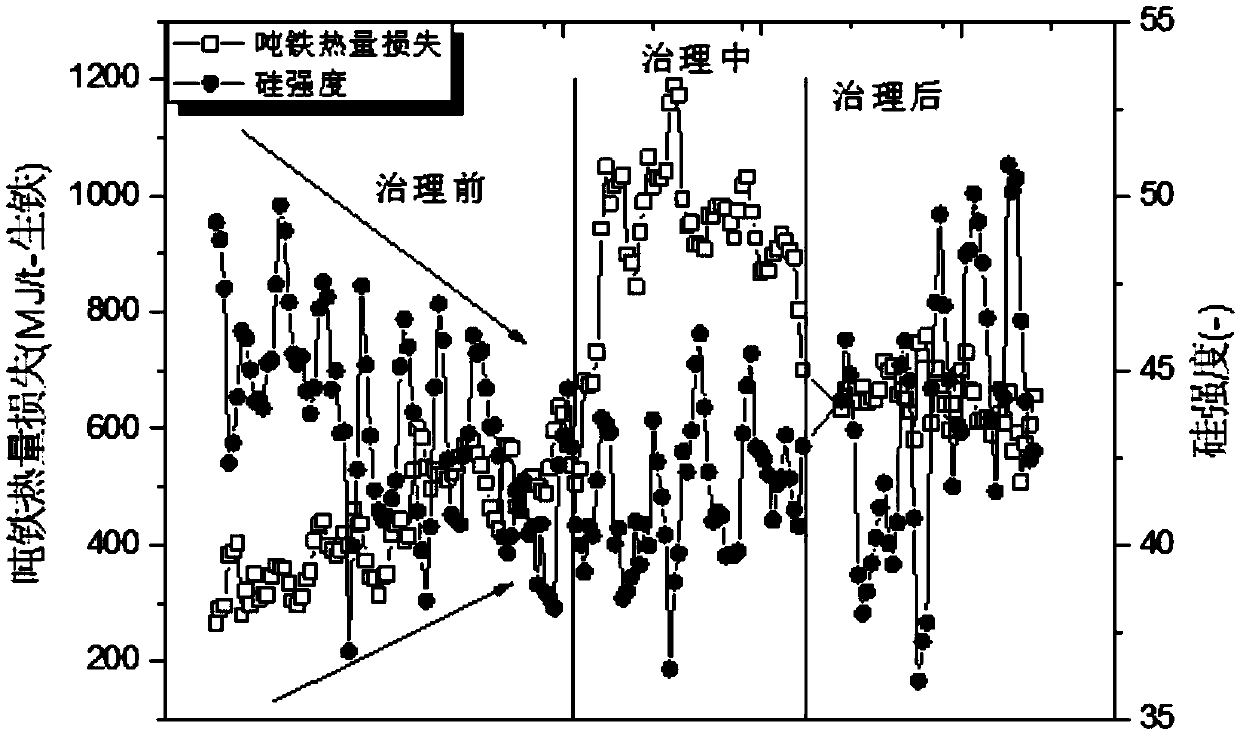

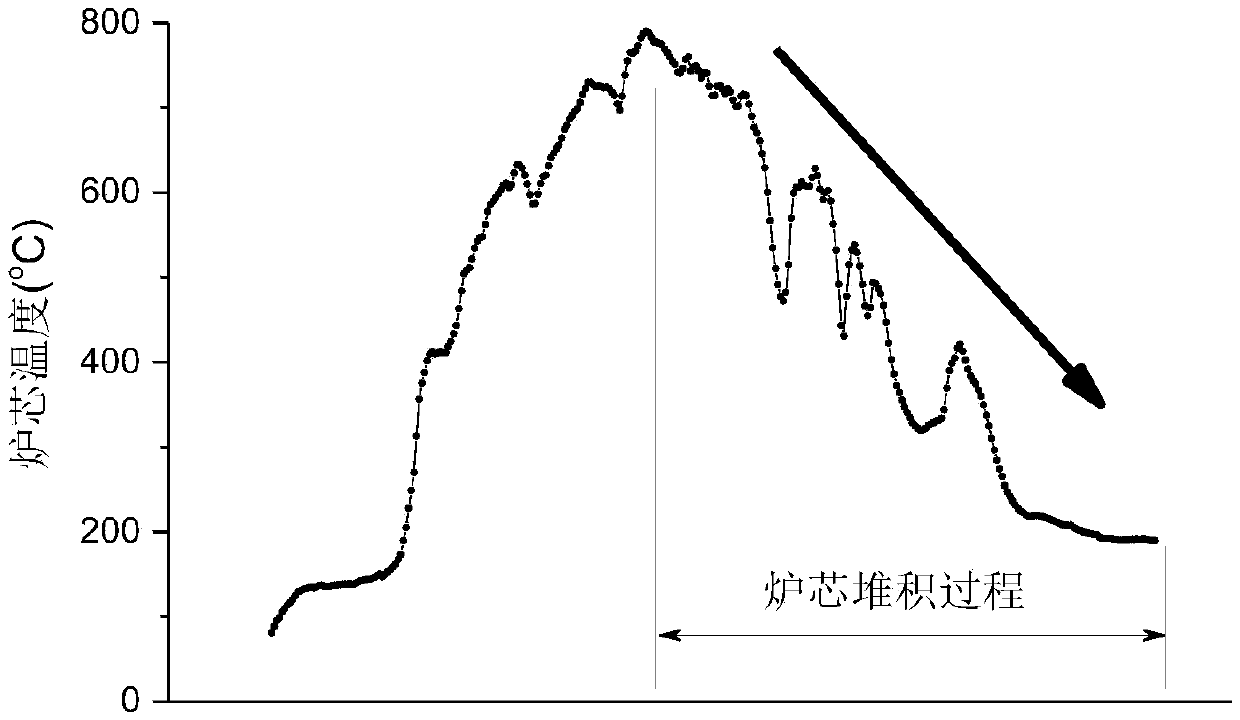

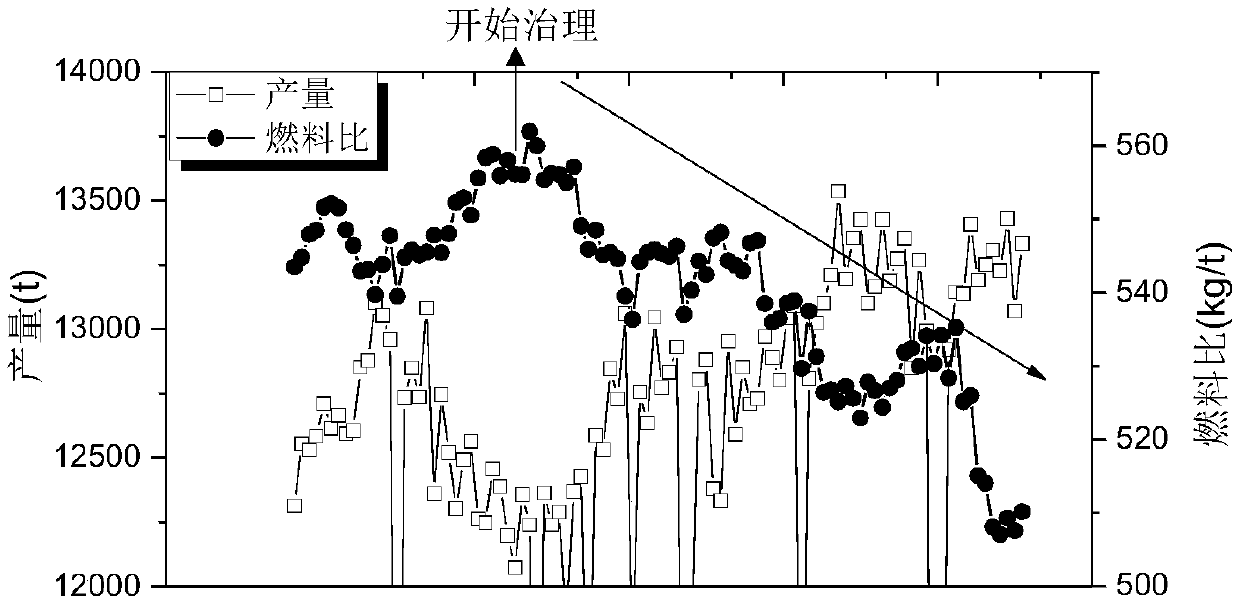

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In the present invention, a certain large-scale blast furnace is taken as an example. When the furnace condition is stable, the average daily output is 13,200 tons / day, and the fuel ratio is 515kg / t; keep climbing. During this process, the blast furnace continued to run forward, and the air volume and blowing function could maintain normal. There were no frequent material collapses and top pressure peaks, and there was no particularly difficult situation in slag and iron removal. It was just that the fuel was relatively high, and the cross The temperature of the temperature measurement center is high and wide, and the temperature of the bottom and side walls of the furnace has dropped in an all-round way.

[0039] In view of the above situation, adopt the present invention to judge whether the above-mentioned abnormality is caused by the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com