A Timing Aging Device for Ignition Electric Nozzle

A thermal power and sophisticated technology, applied in the direction of jet propulsion devices, gas turbine devices, machines/engines, etc., can solve the problems of loss of ignition device life, low degree of automation, poor economy, etc., to avoid shortening the service life, expand the internal space, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

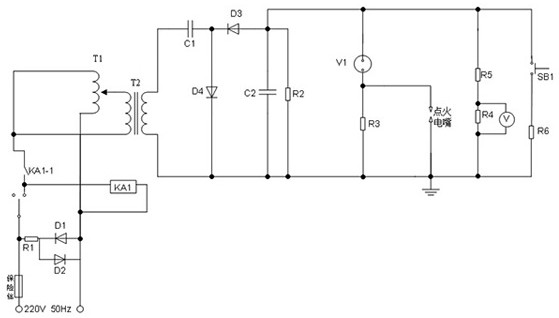

[0017] combined with figure 1 As shown, a timing aging device for an ignition nozzle includes an ignition nozzle, and also includes a timing switch circuit, a voltage regulation boost circuit, a voltage doubler energy storage circuit and a discharge circuit. The timing switch circuit includes a timer KA1 and a timer The relay KA1-1 connected to the device KA1; the voltage regulation and boosting circuit includes an autotransformer T1 and a voltage booster T2, and the autotransformer T1 regulates the secondary voltage by adjusting the primary-to-secondary turn ratio, and the boost Transformer T2 boosts the secondary output of autotransformer T1; the voltage doubler energy storage circuit includes capacitor C1, silicon stack D3, silicon stack D4 and energy storage capacitor C2, when the voltage output by step-up transformer T2 makes the silicon stack When D4 is turned on, the step-up transformer T2 charges the capacitor C1, and the voltage on the capacitor C1 is equal to the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com