Direct-driving motor with single-bearing structure

A direct-drive motor and single-bearing technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of fixed shaft position, difficult coordination, and inability to adjust, so as to reduce materials, shorten assembly process, and increase installation matching sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

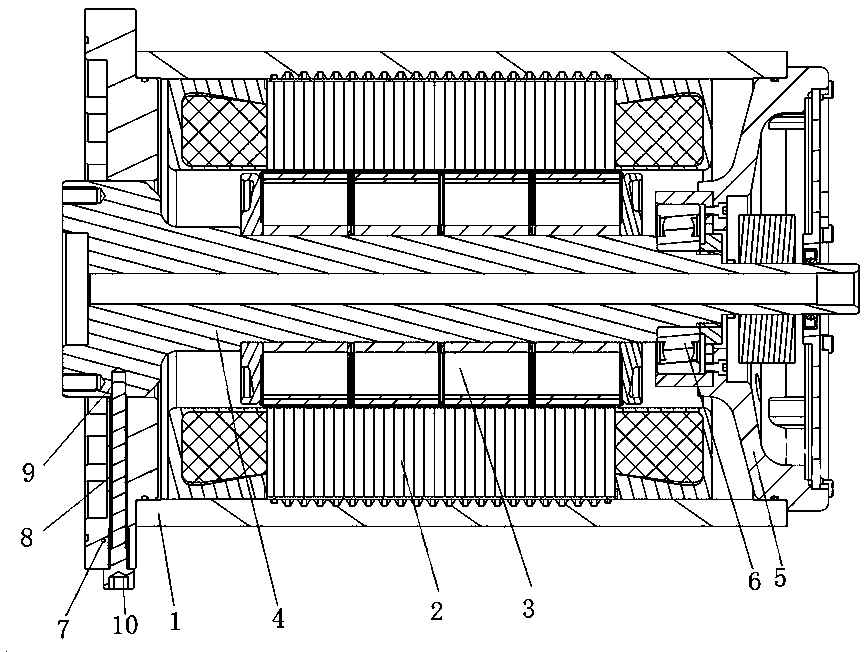

[0016] The following is based on figure 1 The specific embodiment of the present invention is further described:

[0017] see figure 1 , a direct drive motor with a single bearing structure, including a motor housing 1, a stator assembly 2, a rotor assembly 3, a front flange 7 and a rear flange 5, and the inner side of the motor housing 1 is connected with a stator assembly 2 A rotor assembly 3 is arranged inside the stator assembly 2, a front flange 7 is connected to one end of the motor housing 1, and a rear flange 5 is connected to the other end of the motor housing 1, and the rear flange The middle part of 5 is provided with a rear through hole and one side of the rear through hole is provided with a bearing chamber, the rotating shaft 4 in the rotor assembly 3 is sleeved and connected with the inner ring of the bearing 6, and one end of the rotating shaft 4 is connected from the rear The rear through hole of the flange 5 protrudes and the bearing 6 on the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com