Outdoor antifreezing and damp-proof type fire hydrant used for low-temperature environment ship

A low-temperature environment and fire hydrant technology, applied in the field of shipbuilding, can solve problems such as easy to freeze, inconvenient use, and high energy consumption, and achieve the effect of saving energy consumption and reducing installation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the explanatory text.

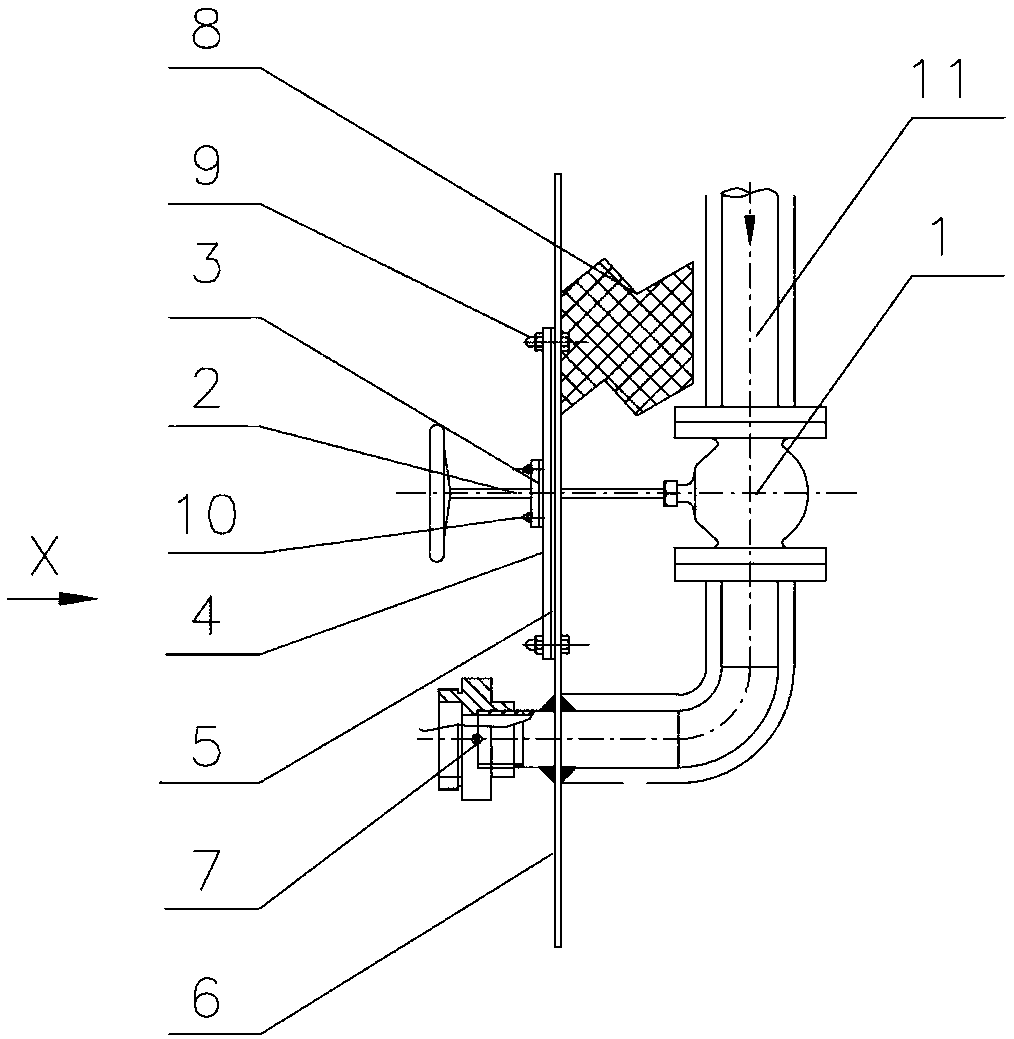

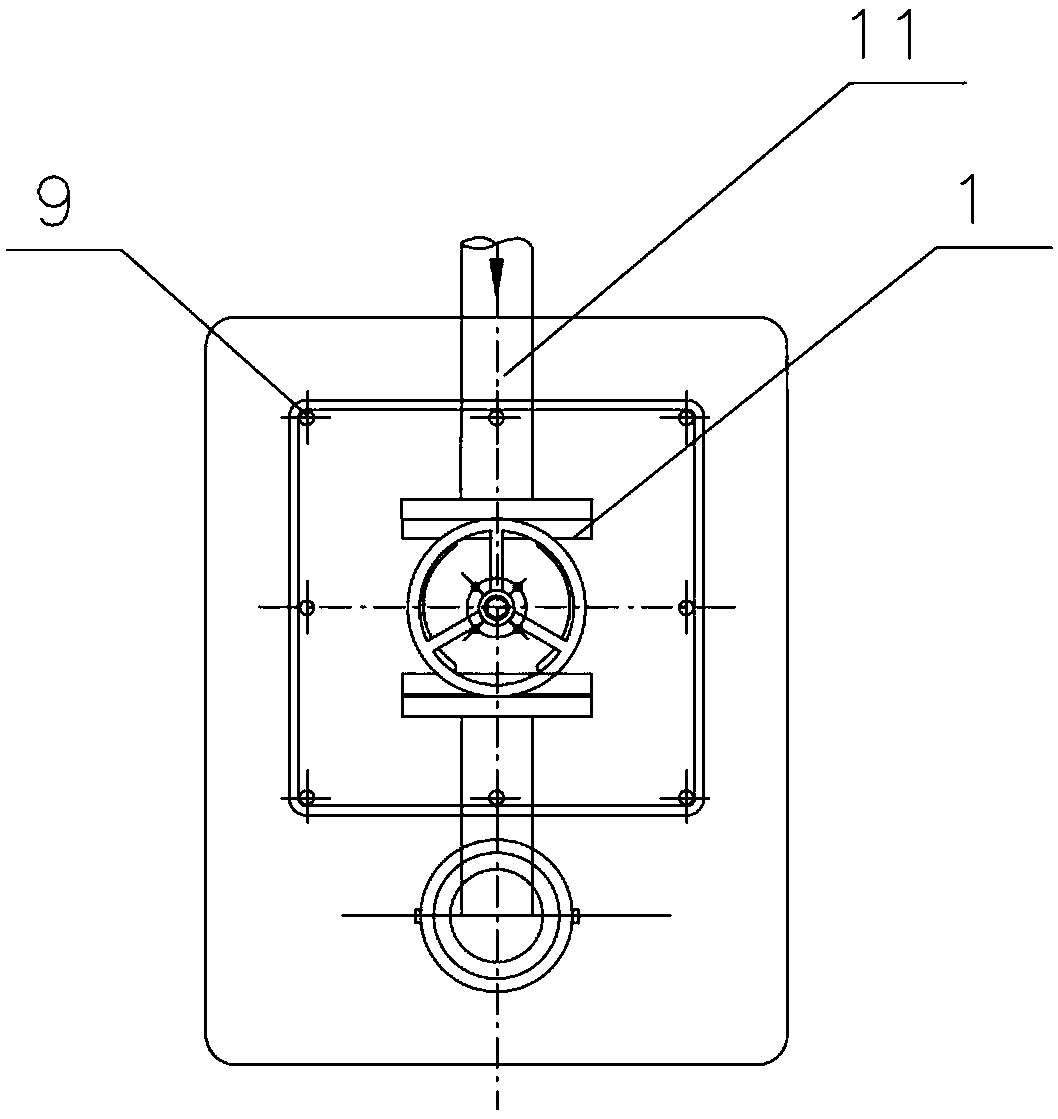

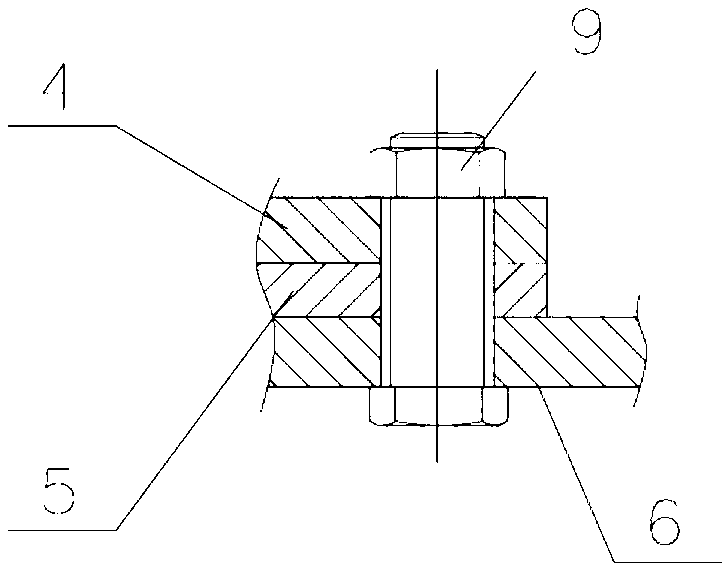

[0045] Such as Figure 1-4 As shown, the present invention provides an open-air antifreeze wet fire hydrant for low-temperature environment ships. The open-air antifreeze wet fire hydrant for low-temperature environment ships includes a fire valve 1, a fire valve extension rod 2, an extension rod seal 3, a cover plate 4, and a cover plate Sealing 5, bulkhead 6, fire hydrant joint 7, insulation layer 8, cover plate fixing bolt 9, extension rod sealing fixing bolt 10, fire water pipe 11.

[0046] The above-mentioned open-air antifreeze wet fire hydrant for ships in low temperature environment, the water inlet of fire valve 1 is connected with the upper fire pipe 11, and the water outlet of fire valve 1 is connected with fire hydrant joint 7 through a short pipe; fire valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com