Air supply recovery method

A recovery method and air volume technology, applied in the field of blast furnace smelting, can solve problems such as gas abnormality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

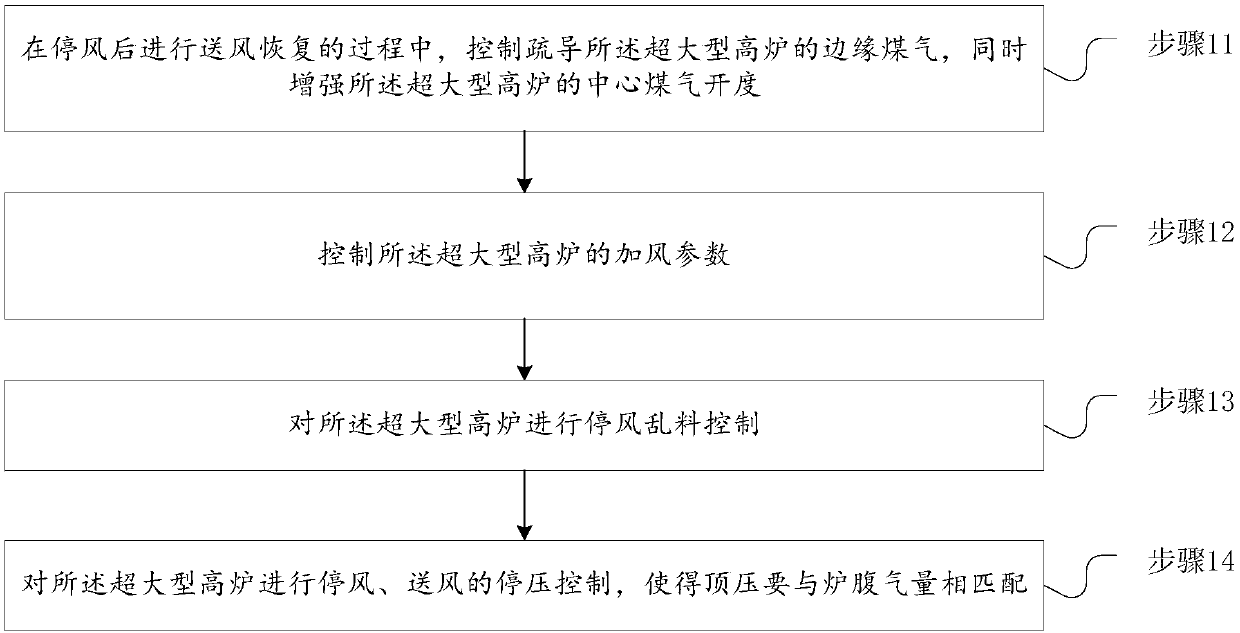

[0041] The invention discloses a method for recovering air supply, which is mainly aimed at ultra-large blast furnaces (with an effective volume of 4000m 3 ) under heavy load (coke load greater than 5.50) and large coal ratio (coal ratio higher than 195kg / t) smelting conditions, the key and difficult problems in the process of air supply recovery are comprehensively analyzed during air stop and air supply. Applying blast furnace adjustment and operation methods can make the blast furnace reach full capacity as soon as possible, avoid fluctuations in furnace conditions, effectively shorten recovery time, improve blast furnace production efficiency, and reduce smelting components.

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com