Vehicle door with an outside handle unit and methods of assembling the same

A technology of outer handle and car door, applied in the direction of lock application, vehicle lock, thin plate connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

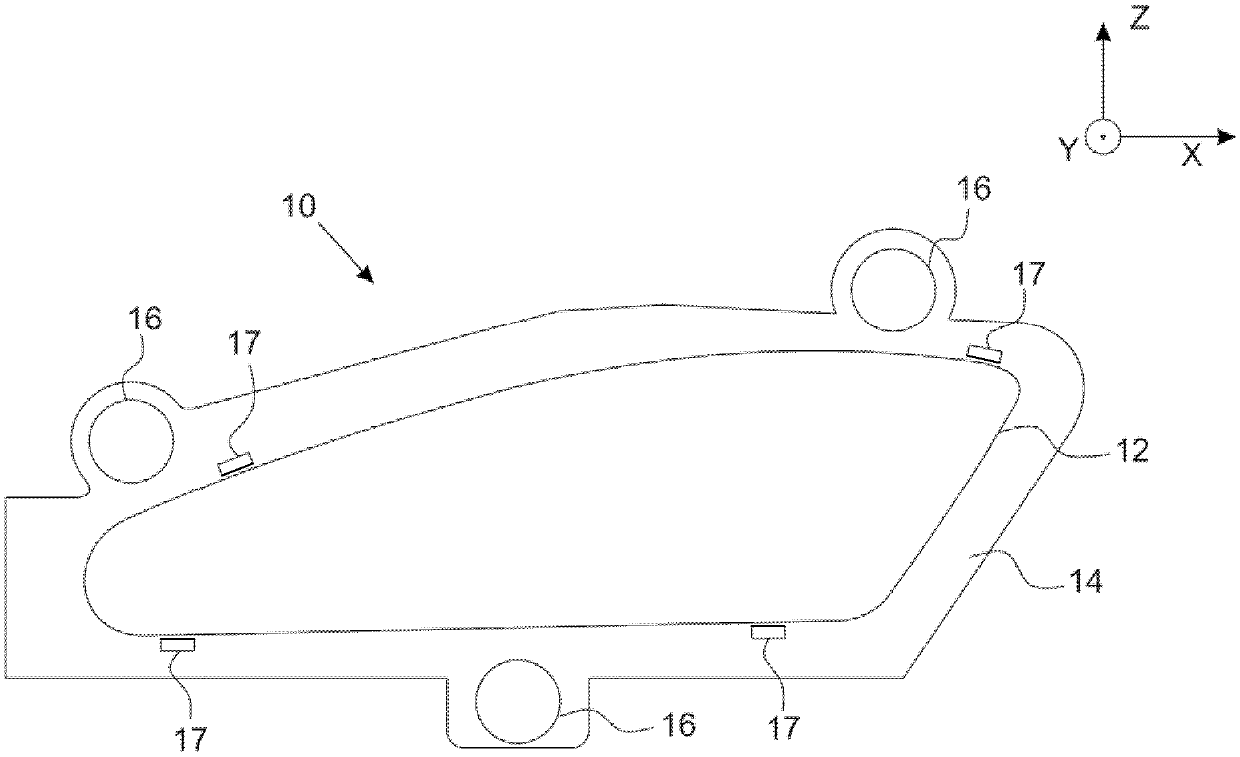

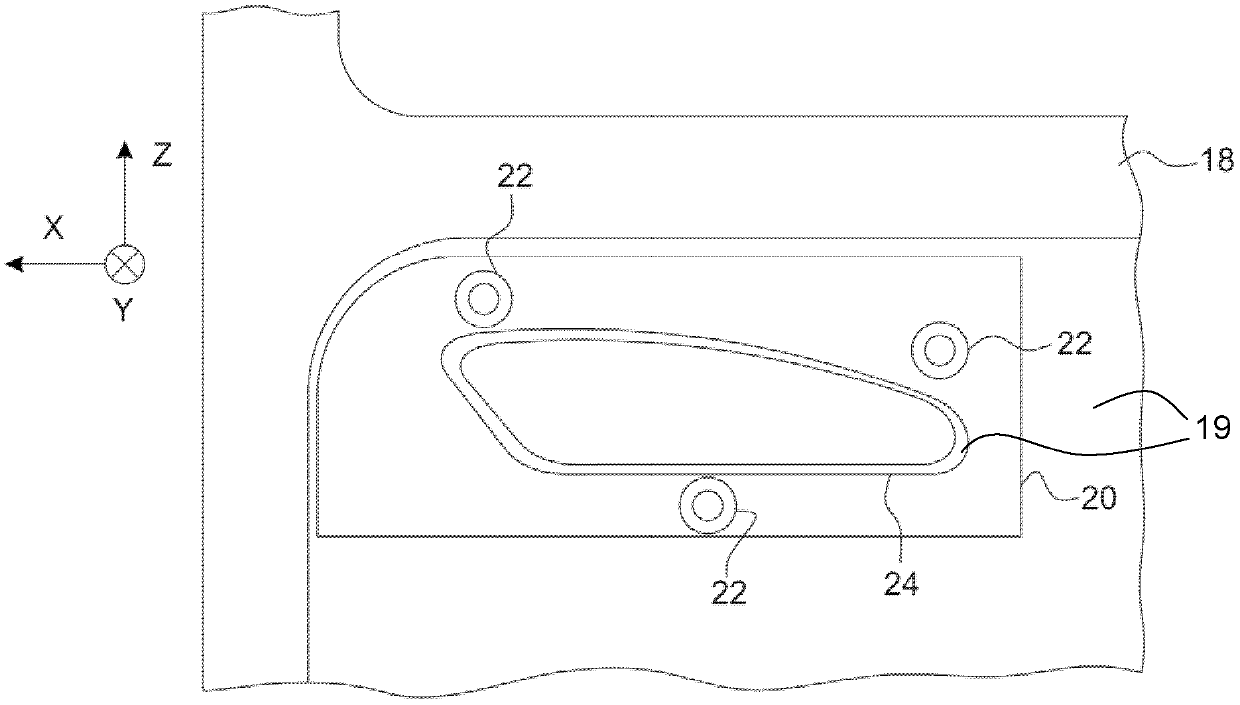

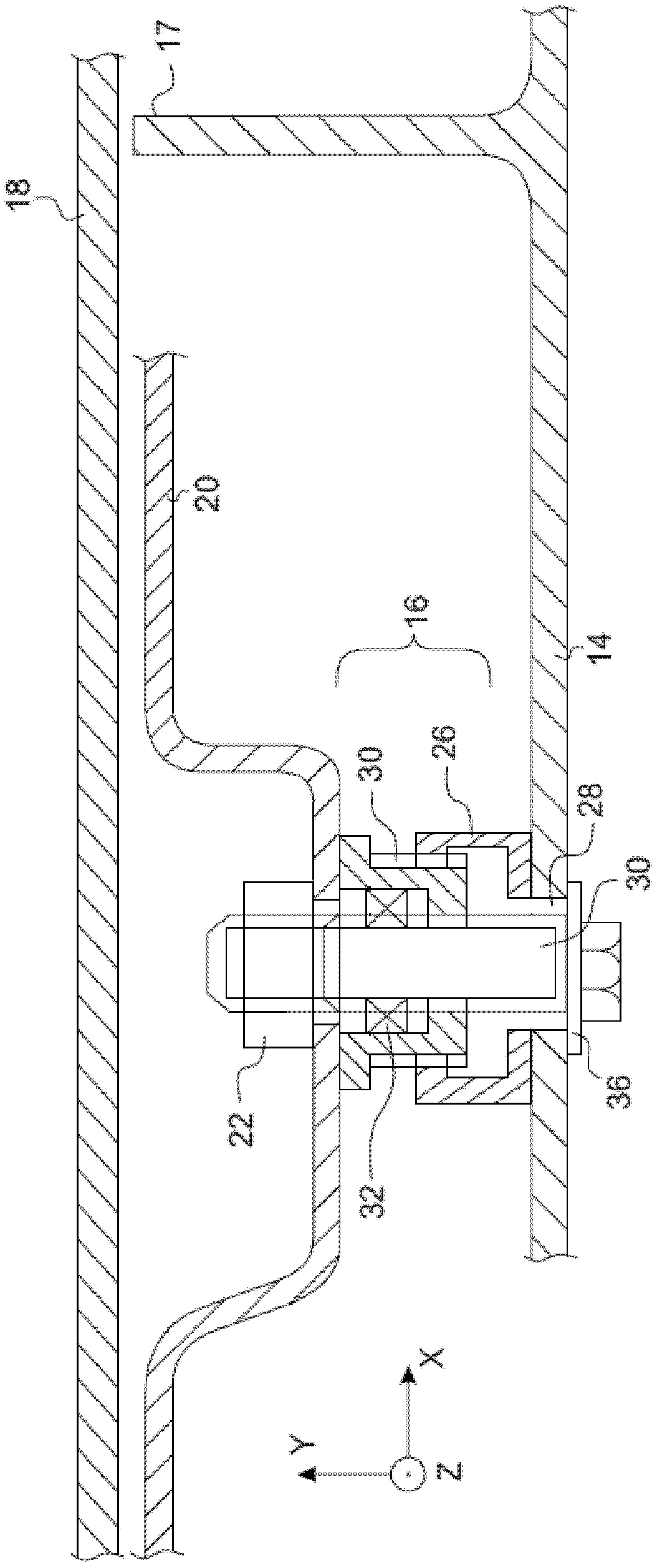

[0022] figure 1 Schematic view from the outside of the outer handle unit 10, which comprises a handle bow 12 and a carrier part 14, in which a not-shown mechanism and a door lock for connection to the mechanism by means of a soft-sleeve cable are accommodated of the servo drive. If it is the driver's door, a lock cylinder unit not shown is also contained therein. A certain number (here three, but also other numbers) of compensating elements 16 are arranged on the circumference of the carrying part 14, and they are image 3 is further shown in . The compensating element 16 can previously be mounted on the carrier part 14 by means of a snap-in lug connection or otherwise. In addition, three or four oriented projections 17 are attached or formed on the carrier part 14 around the handle bracket, and should be located as close as possible to the compensating element 16 . These oriented bulges have an extension of a few millimeters in the Y...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap