A feeding device in an automatic production line

A technology of automatic production line and unwinding device, which is used in thin material handling, transportation and packaging, winding strips, etc. Crop offset and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

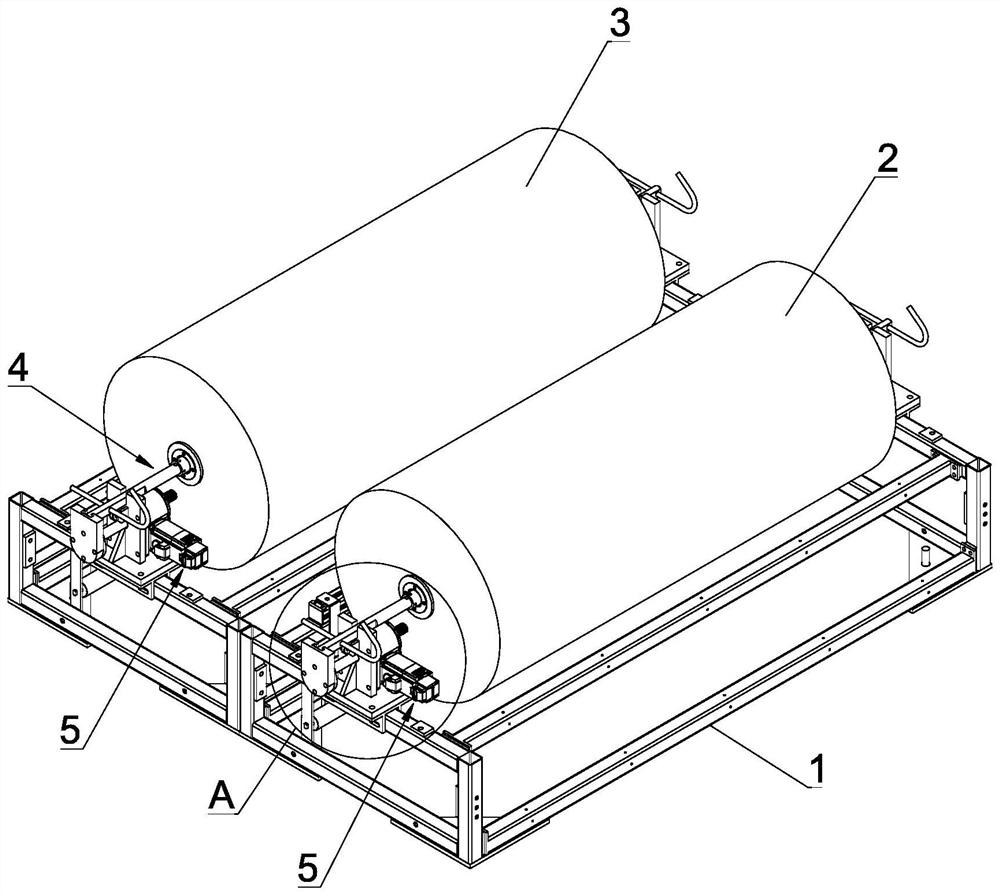

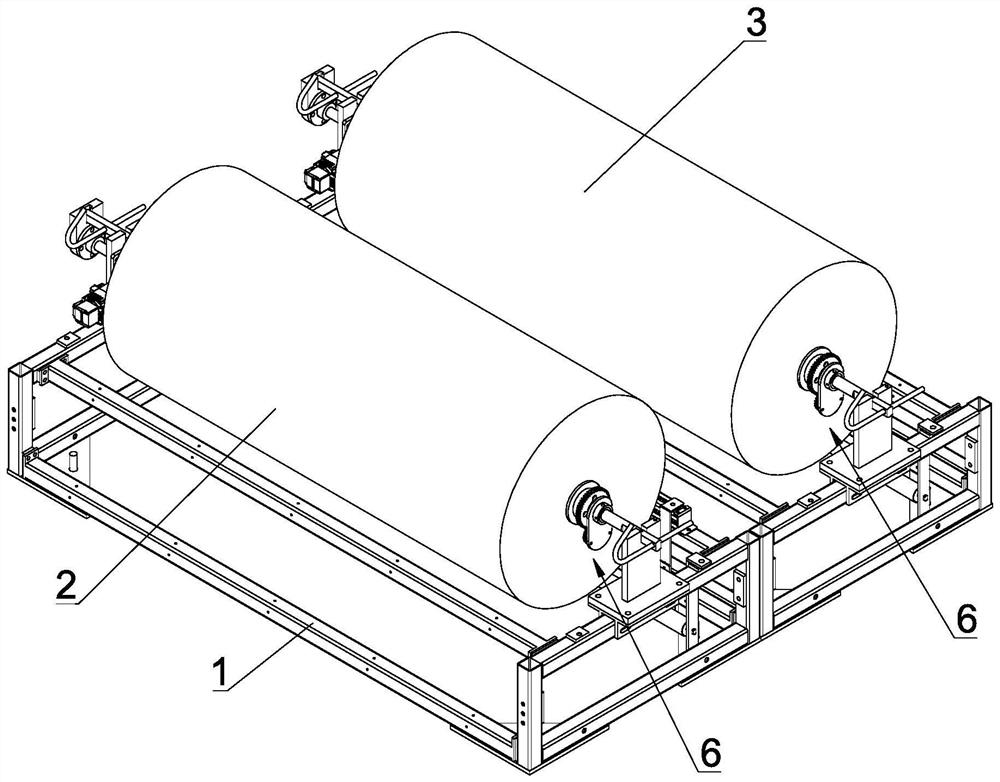

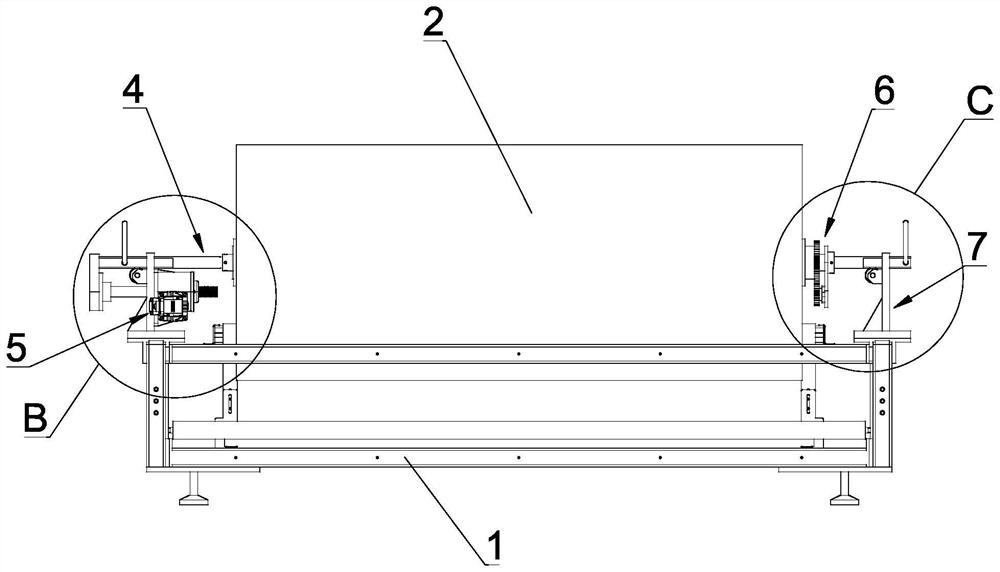

[0037] see Figure 1-Figure 8 , a discharge device in an automatic production line, comprising a frame 1, an upper layer of non-woven fabric roll 2 and a lower layer of non-woven fabric roll 3 rotated on the frame 1; along the conveying direction of the non-woven fabric, the lower layer The non-woven roll 3 is arranged in front of the upper non-woven roll 2; the upper non-woven roll 2 and the lower non-woven roll 3 are all installed on the frame 1 by a discharge roller 4; wherein,

[0038] One end of each of the discharge rollers 4 is provided with a deflection correction drive mechanism 5 for driving the discharge roller 4 to reciprocate along its axial direction, and the other en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap