Exhaust turbochargers for internal combustion engines

An exhaust turbine and supercharger technology, which is applied to gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of increased installation cost, increased failure risk, and increased installation cost of exhaust turbochargers. The effect of reducing the working gap, reducing the total cost and reducing the installation investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the description of the figures, the same reference numerals refer to the same elements.

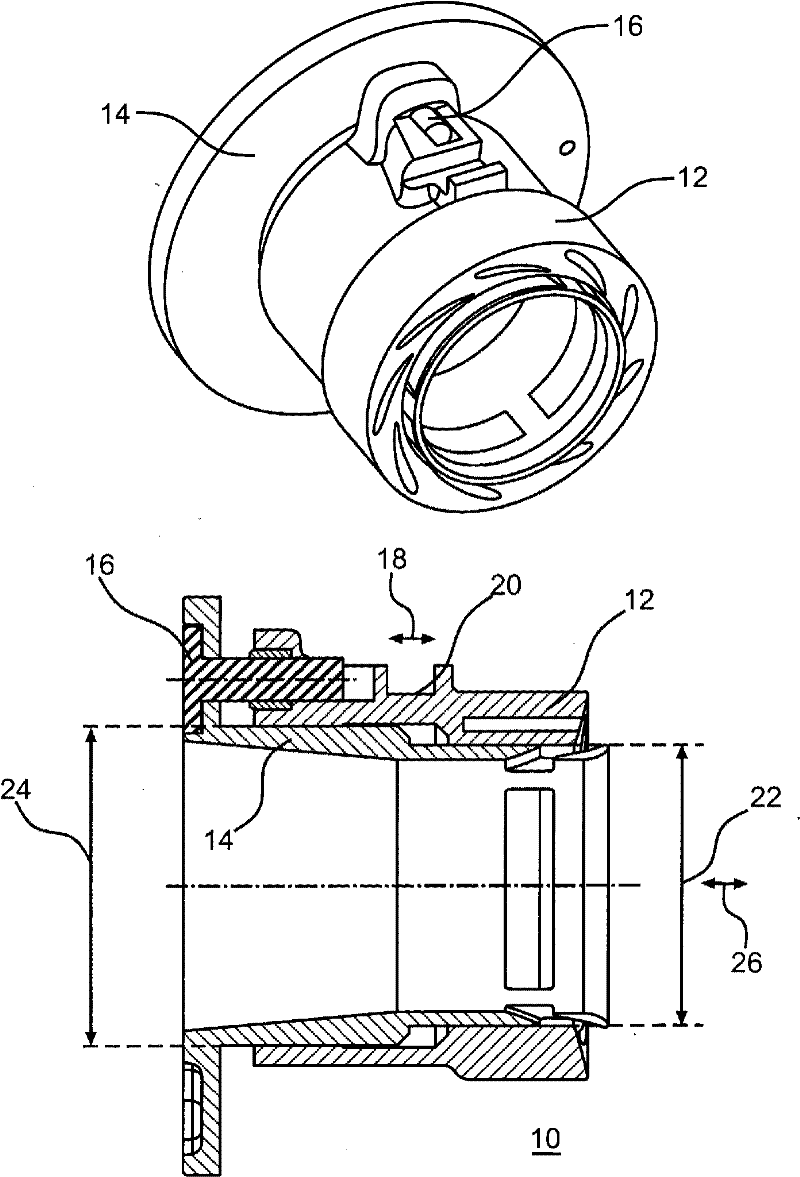

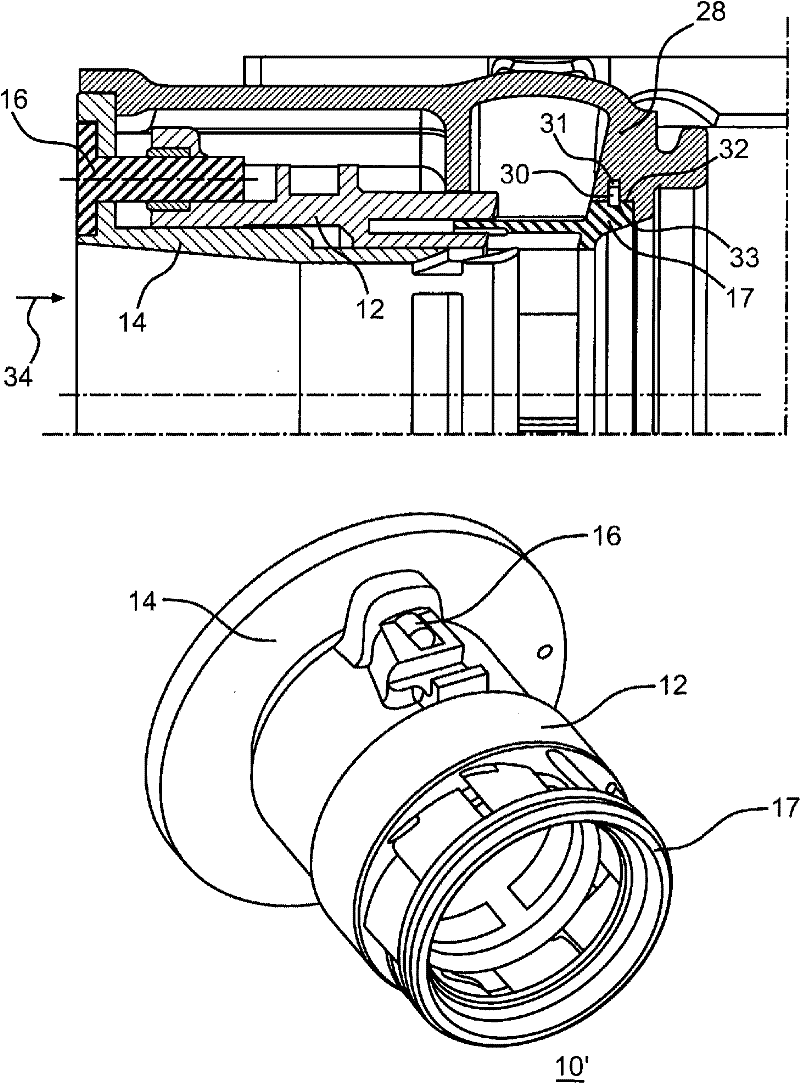

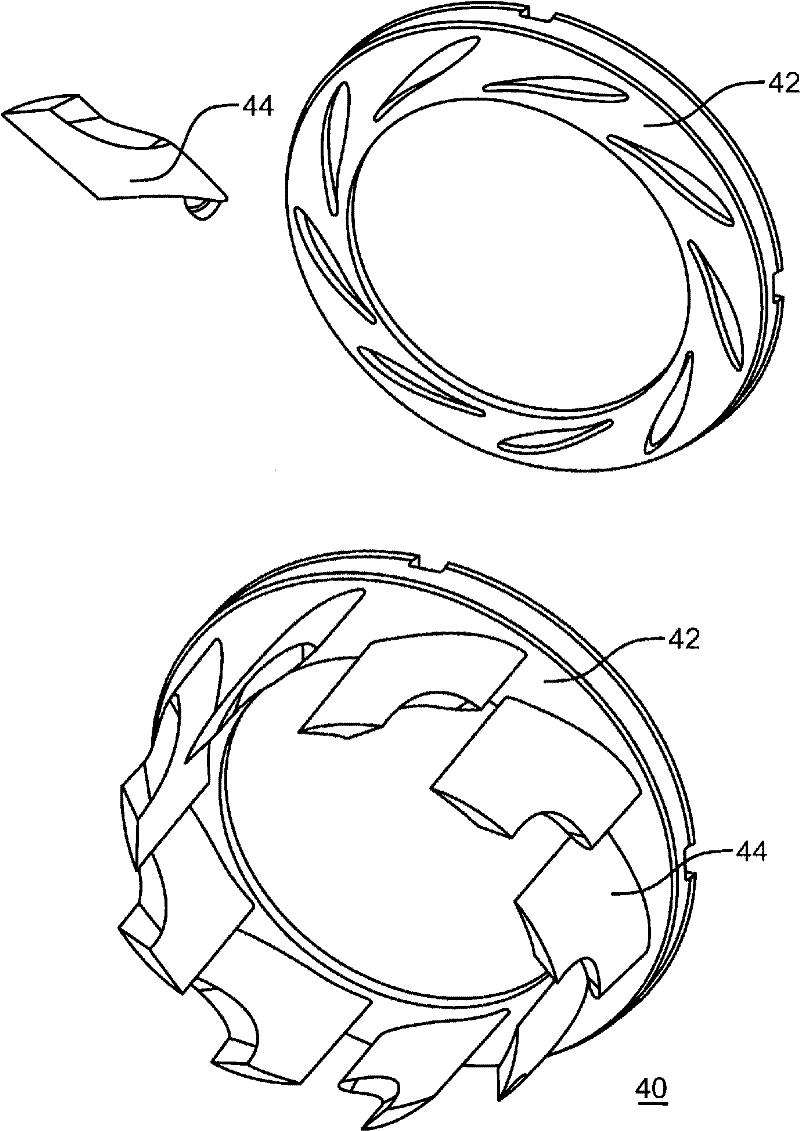

[0039] figure 1 shows a combination of an axial slide for influencing the flow parameters in the region of the turbine inlet and a profiled sleeve for influencing the flow parameters in the region of the turbine outlet, whereas in figure 2 middle, figure 1 A one-piece guide grid is added to the assembly in , and the installation of the assembly in the turbine housing of an exhaust-gas turbocharger is shown, the one-piece guide grid has multiple A guide vane sinks into the guide vane base of the axial slide. image 3 A possible embodiment of a multi-part guide grid with a guide vane base body and a plurality of guide vanes is shown. Figure 4 shows the basis figure 2 The installation of the assembly, where, in Figure 4 , the one-piece guide grille is based on image 3 The multi-piece guide grid replacement, wherein the multi-piece guide grid is fixed in the turbine housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com