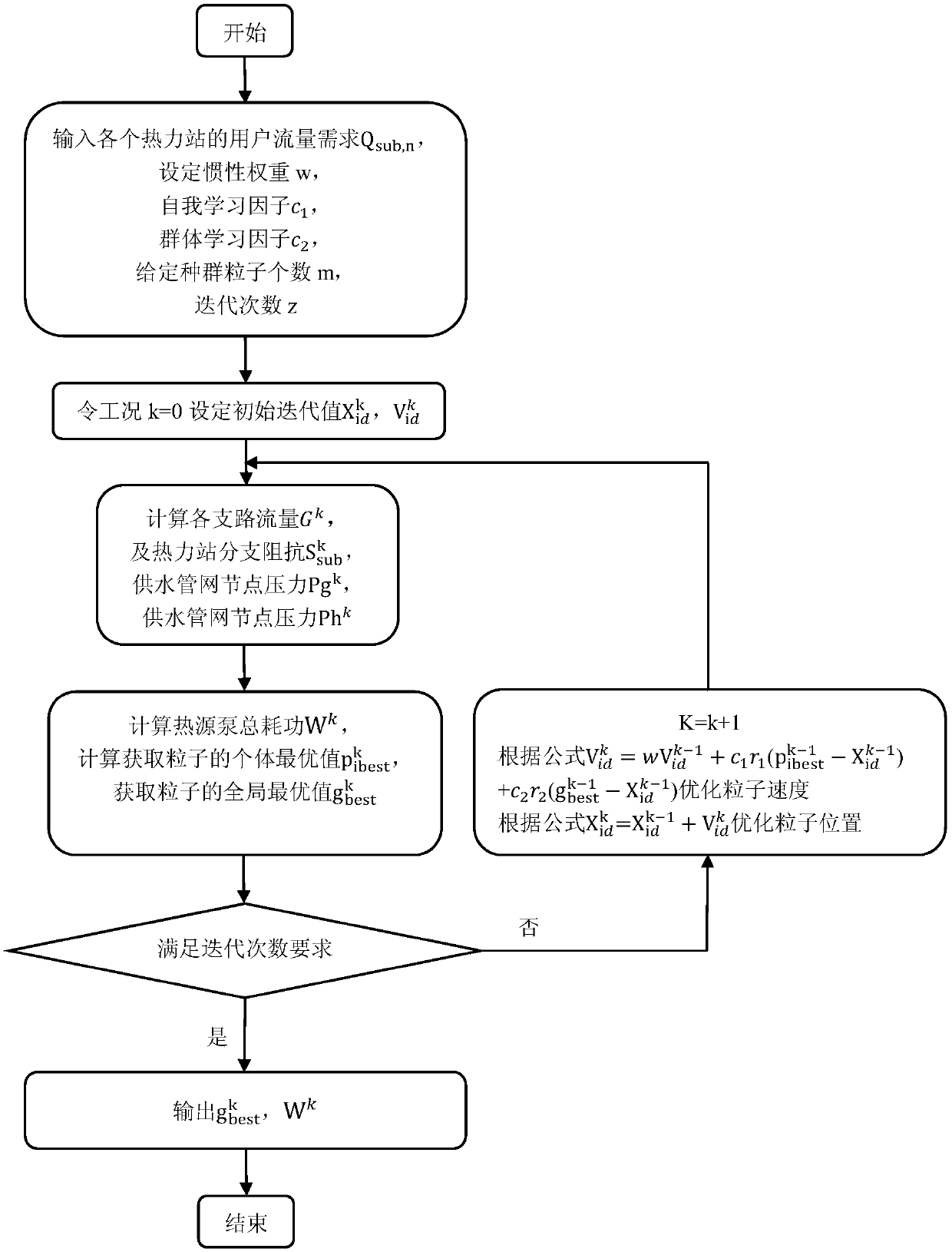

Multi-heat-source annular heat supply network hydraulic optimization scheduling method based on PSO algorithm

A technology of hydraulic optimization and dispatching method, applied in calculation, calculation model, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

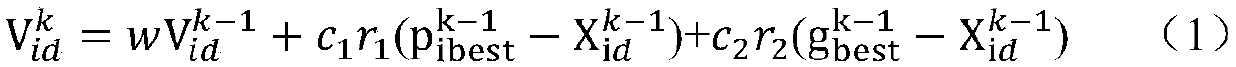

Method used

Image

Examples

Embodiment Construction

[0034]The heat source flow optimization scheduling problem of multi-heat source annular heating network can be summarized as the following optimization problem: the primary network adopts flow regulation, so the water supply temperature of the primary network is a fixed value, and the flow rate of each thermal station can be obtained from the outdoor temperature and the return water temperature of the primary network The demand (known quantity), the flow rate and head of the circulation pump of each heat source are unknown quantities, aiming at the minimum energy consumption of the circulation pump of all heat sources, on the premise of meeting the flow demand of each heat station, adjust the flow distribution and distribution of each heat source The impedance of the valves in the thermal station realizes the optimal scheduling of hydraulic conditions. The optimization problem can be described as follows:

[0035] Objective function:

[0036] Restrictions:

[0037] A·G k =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com