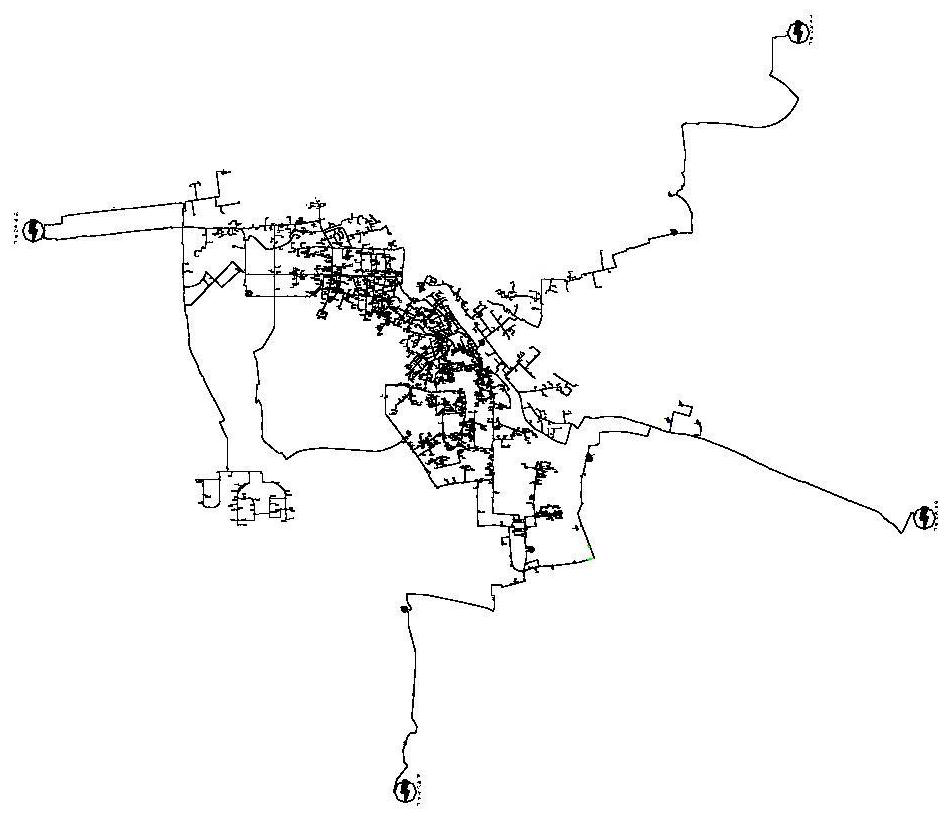

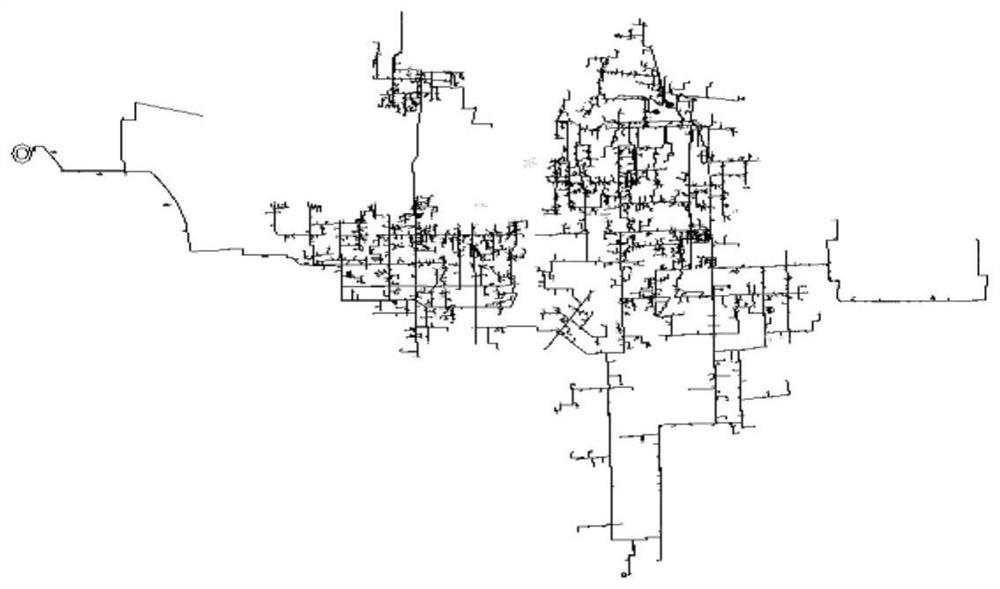

A Method for Optimizing the Scheduling of Hydraulic Working Conditions of Multi-Heat Source Annular Central Heating Pipe Network

A technology for central heating and optimal scheduling, which is used in heating methods, household heating, heating systems, etc. to achieve reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

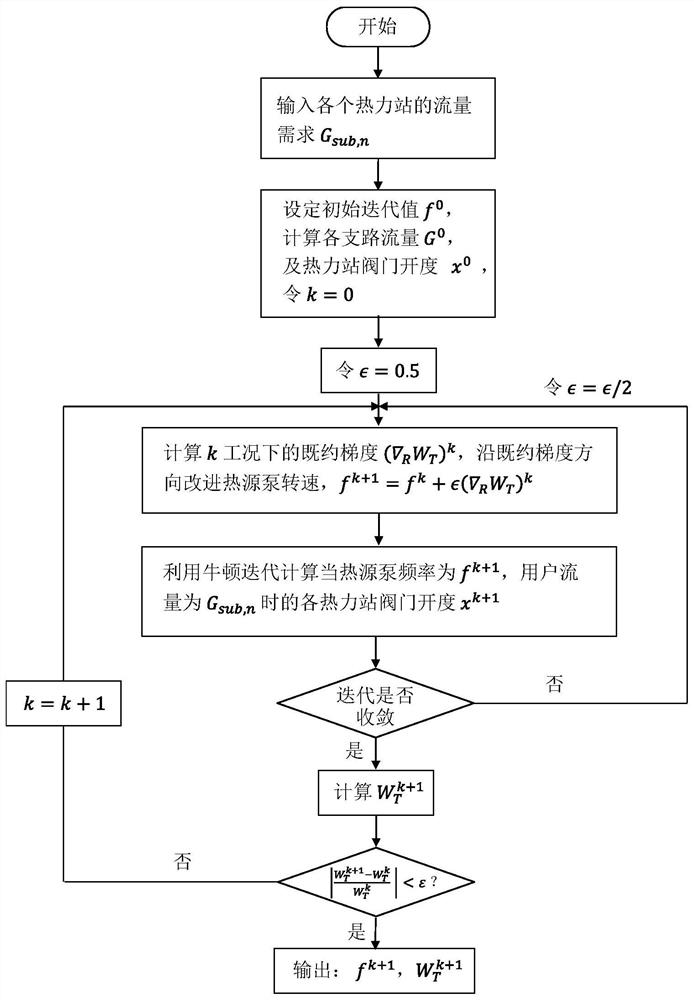

[0031] The optimal scheduling problem of heat source flow in multi-heat source ring network can be reduced to the following optimization problem: under a certain water supply temperature, the flow demand of each end is known, and the flow and head of each heat source are unknown, the goal is to minimize the energy consumption of transmission and distribution , to optimize the optimal speed of each heat source pump and the valve opening of the end user to meet the needs of users. The optimization problem can be described as:

[0032] Objective function:

[0033]

[0034] Restrictions:

[0035] A·G=0 (2)

[0036] A T ·P=S·G a ·G+H (3)

[0037] G sub =G sub,n (4)

[0038] S sub,a ≥S sub,n (5)

[0039] 30Hz≤f j ≤50Hz (6)

[0040] Among them, W T is the total power of the heat source pump; g sc,j is the flow rate of the jth heat source pump; f j is the frequency of the jth heat source pump; H j (g sc,j , f j ) is the lift characteristic curve of the jth heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com