Elevator suspension sheave device and method for mounting suspension sheave device

A technology of hanging wheels and elevators, applied in the directions of transportation, packaging, elevators, etc., can solve the problem of beams not being arranged in parallel, and achieve the effect of changing the installation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

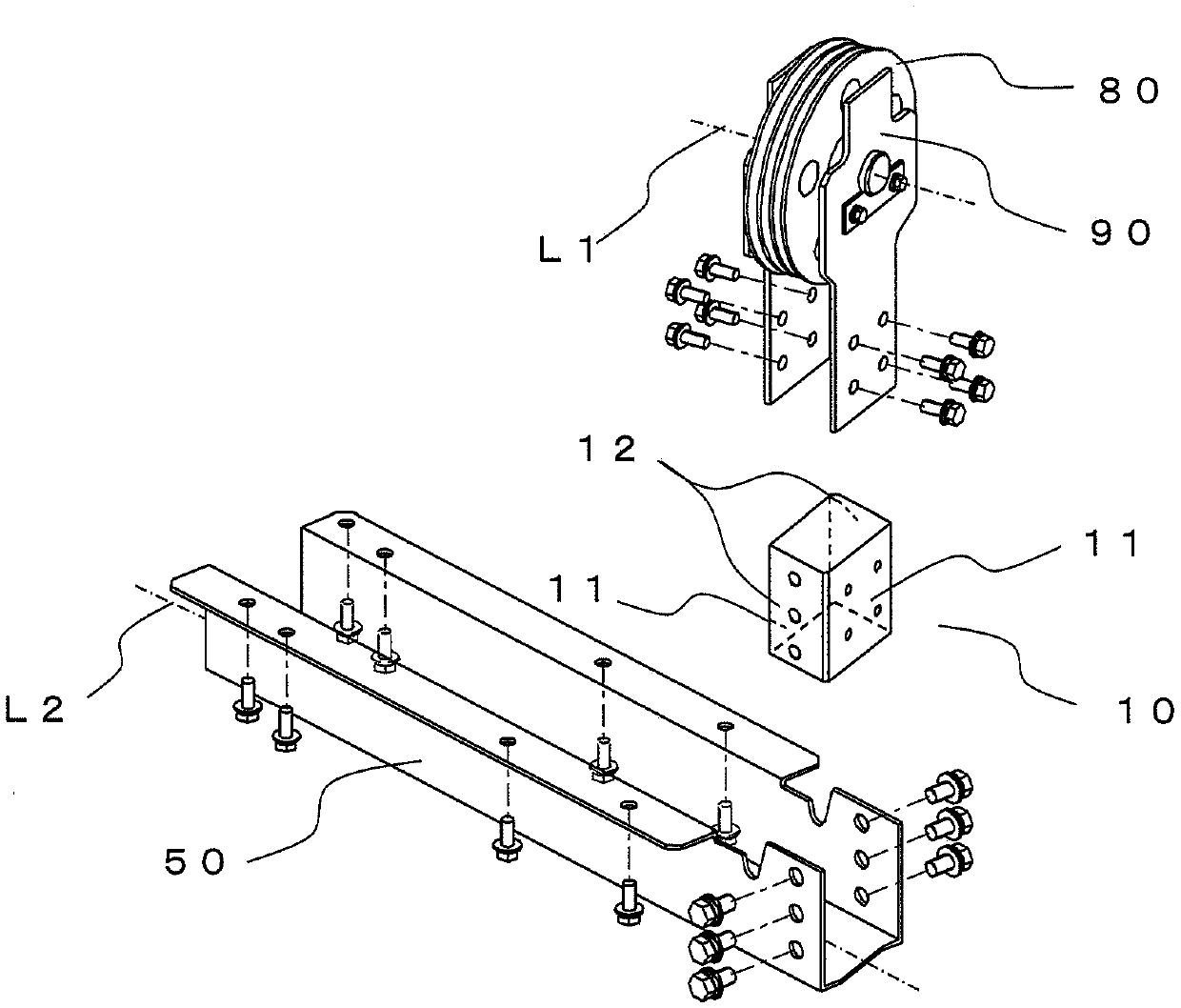

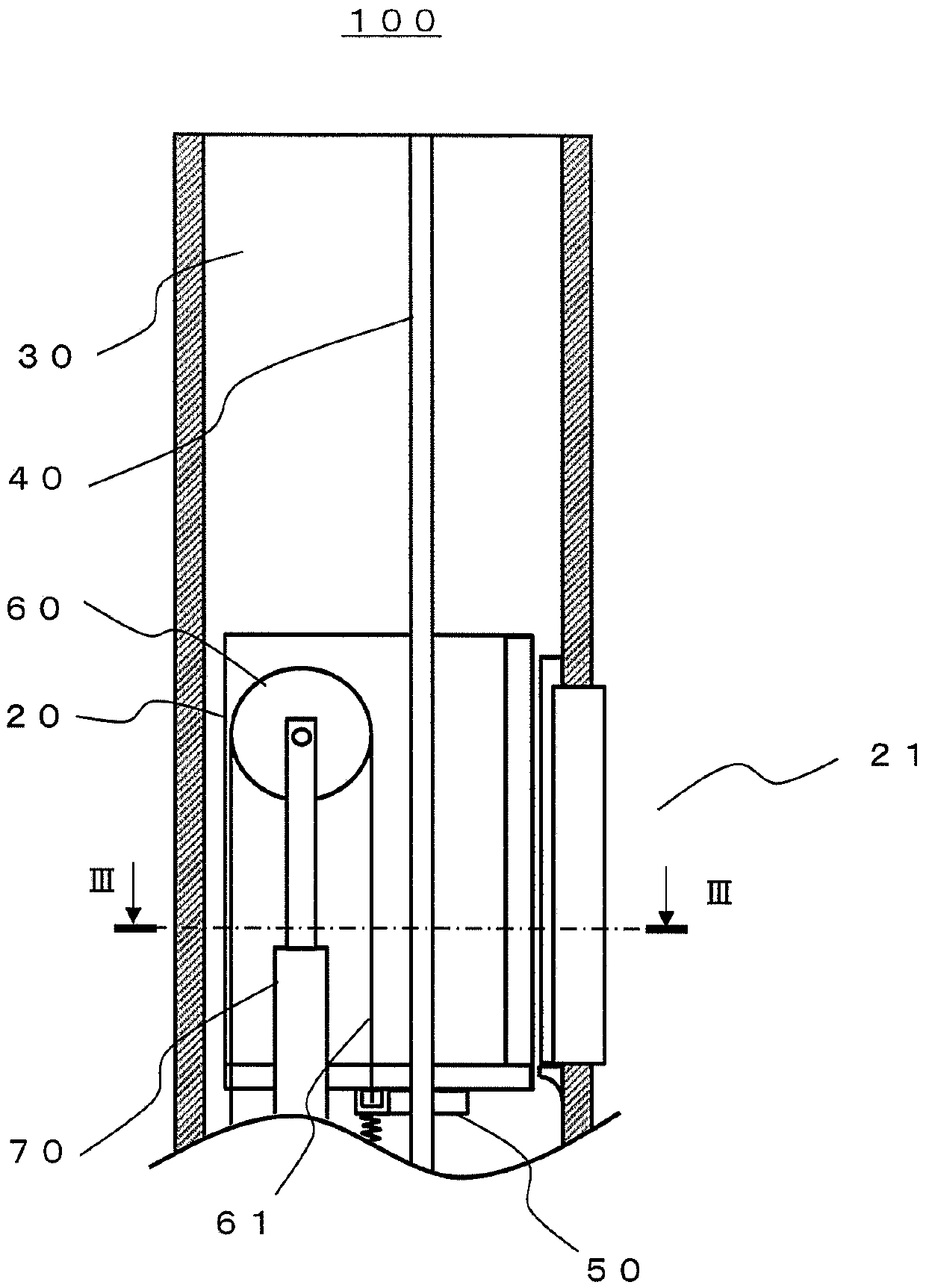

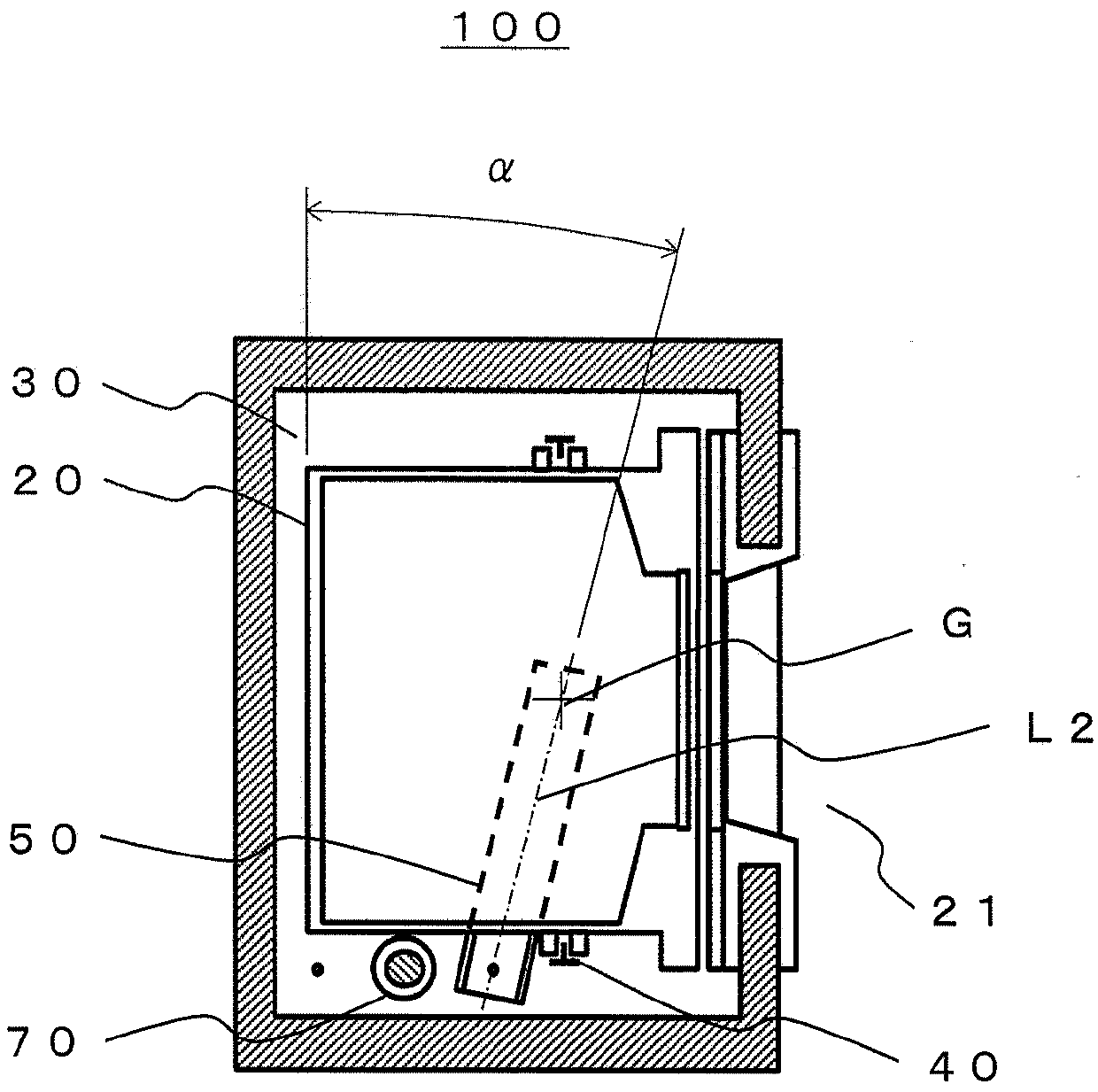

[0024] figure 1 It is a configuration diagram showing the suspension wheel device in Embodiment 1 of the present invention. Such as figure 1 As shown, the suspension wheel device has a support plate 90 for supporting the suspension wheel 80 , a beam 50 , and a connection body 10 for connecting the support plate 90 and the beam 50 . The support plate 90 is constituted by a pair of plate-shaped members, and supports the suspension pulley 80 so that the suspension pulley 80 is sandwiched by the pair of plate-shaped members from the direction of the rotation axis L1 of the suspension pulley 80 . Four through-holes for fastening the support plate 90 to the coupling body 10 are respectively provided at the ends of a pair of plate-shaped members constituting the support plate 90 .

[0025] The connecting body 10 is constituted by a hexahedron, the cross-section in the horizontal direction parallel to the top surface forms a parallelogram, and the adjacent side surfaces form a non-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com